Abstract

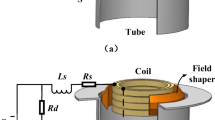

Electromagnetic forming (EMF) is a technology that uses Lorentz force to drive the deformation of light alloy. In the processing of small metal pipe fittings, attraction forming is beneficial to reduce the design requirements of forming coils and the application cost of actual tooling. However, the attractive dual-frequency current method requires strict matching between currents. This will lead to difficulty in controlling and changing the attractive force, thus reducing the uniformity of the deformation of the workpiece. To solve this problem, a field shaper is introduced to optimize the distribution of electromagnetic force and improve the uniformity of pipe forming. The finite element model including circuit field, electromagnetic field, and structure field was established, and the bulging of an aluminum alloy pipe fitting with a radius of 10 mm and a length of 40 mm under the action of 9-kV power supply was simulated. The results show that the deformation uniformity is increased by 15% and the degree of shape change is increased by 8.9% with the addition of field shaper. It is proved that field shaper can improve the uniformity of pipe fitting.

Similar content being viewed by others

Data availability

All the data have been presented in the manuscript.

Code availability

Not applicable.

References

Xiong Q, Tang H, Wang M, Huang H, Jiang J, Qiu L (2019) Research progress of electromagnetic forming technique since 2011. High Voltage Eng 45(04):1171–1181

Psyk V, Risch D, Kinsey BL, Tekkaya AE, Kleiner M (2011) Electromagnetic forming a review. J Mater Process Technol 211(5):787–829

Xiong Q, Cao Q, Han X, Lai Z, Deng F, Zhang B, Zhang X, Chen Q, Li L (2016) Axially Movable Electromagnetic Forming System for Large-Scale Metallic Sheet. IEEE Trans. Appl. Supercond.26(4):1–4

Hong X, Huang L, Li J, Ma F, Lin L (2016) Numerical simulation of electromagnetic bulging of large diameter aluminum alloy bellows. Journal of Netshape Forming Engineering 8(04):1–7

Li Z, Li C, Zhao C(2006) Research on forming limit of electromagnetic tube bulging. Forging & Stamping Technology 06:52–55

Yu H, Li C, Li Z (2006) Numerical simulation of coupled fields of electromagnetic forming for tube-compression based on FEM. J Mech Eng 07:231–234

Pawar S, Kore SD (2019) Electromagnetic forming and perforation of Al tubes. J. Mech. Sci. Technol 33(12):5999–6007

Zieve PB (1991) Power supply for electromagnetic proof load tester and dent remover. US Patent 5:046,345

Cao Q, Lai Z, Xiong Q, Chen Q, Ding T, Han X, Li L (2016) Electromagnetic attractive forming of sheet metals by means of a dual-frequency discharge current: design and implementation. Int J Adv Manuf Technol 90(1-4):1–8.9

Xiong Q, Yang M, Liu X, Song X, Qiu L, Jiang J, Yu K (2020) A dual-coil method for electromagnetic attraction forming of sheet metals. IEEE Access 8:92708–92717

Rajak AK, Kumar R, Basumatary H, Kore SD (2018) Numerical and experimental study on effect of different types of field-shaper on electromagnetic terminal-wire crimping process. Int J Precis Eng Manuf 19(3):453–459

Qiu L, Deng K, Ahmed A, Xiong Q, Yi N, Fan Y, Tian J, Jiang J (2020) Construction and Analysis of Two-Dimensional Axisymmetric Model of Electromagnetic Tube Bulging With Field Shaper. IEEE Access 8:112713–113719

Cao Q, Li L, Lai Z, Zhou Z, Xiong Q, Zhang X, Han X (2014) Dynamic analysis of electromagnetic sheet metal forming process using finite element method. Int J Adv Manuf Technol 74(1-4):361–368

Ouyang S, Li X, Li C, Du L, Peng T, Han X, Li L, Lai Z, Cao Q (2020) Investigation of the electromagnetic attractive forming utilizing a dual-coil system for tube bulging. J Manuf Process 49:102–115

Xiong Q, Huang H, Xia L, Tang H, Qiu L (2019) A research based on advance dual-coil electromagnetic forming method on flanging of small-size tubes. Int J Adv Manuf Technol 102(9):4087–4094

Xu J, Zhou Y, Cui J, Huang L, Zhang X, Li G (2018) Effects of temperature and driver sheet for magnesium alloy sheet in magnetic pulse forming. Int J Adv Manuf Technol 95(9-12):3319–3333

Acknowledgments

The authors would like to thank Song Xianqi and Li Shengfei and Li Qingshan for their contributions in the writing process and also want to thank the support by the funding.

Funding

This work was supported by the National Natural Science Foundation of China (NSFC) under Project Numbers 51707104, the State Scholarship Fund of China under Project Numbers 201908420196, and Sponsored by Research Fund for Excellent Dissertation of China Three Gorges University under Project Numbers 2021SSPY072.

Author information

Authors and Affiliations

Contributions

Qi Xiong: Conceptualization, methodology, formal analysis, writing. Dun Gao: Methodology, software, investigation, writing—original draft. Zhe Li: Software, methodology, visualization. Meng Yang: Software. Xinhui Zhu: Software. Xiang Zhao: Investigation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiong, Q., Gao, D., Li, Z. et al. Electromagnetic attraction bulging of small aluminum alloy tube based on a field shaper. Int J Adv Manuf Technol 117, 511–521 (2021). https://doi.org/10.1007/s00170-021-07732-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07732-w