Abstract

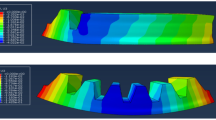

Ring gear is an important part of high power transmission system. Because of its thin wall and low stiffness, it is easy to cause deformation in the process of gear shaping, which affects its accuracy. Therefore, how to ensure the quality of gear ring gear insertion is an urgent research topic. In this paper, the influence of cutting parameters of gear shaper on the deformation of gear ring is studied by finite element simulation and practical test. The results show that the influence of main cutting parameters on the deformation of 42CrMo ring gear is radial feed, circumferential feed, stroke speed, and cutting depth. In the actual gear shaping process, the cutting parameters can be adjusted according to this deformation law, so as to control the deformation of the ring gear.

Similar content being viewed by others

References

Liu ZN, Wang HL, Li HW, Liu XQ (2018) Research on manufacturing technology of high hardness thin-walled ring gear. Mech Design Manuf 08:116–118

Liu XJ (2008) Cutting force model analysis and experimental research of thin-walled parts processing [D]. Chen WF. Nanjing University of Aeronautics and Astronautics, Tutor

Cao BR (2016) Parameter optimization of multi-step turning deformation of parts [D]. Fan HL. Beijing Institute of Technology, Tutor

Pang L (2015) Thermal mechanical coupling simulation analysis and verification of ring gear with weak rigidity [D]. Zuo JH, Beijing University of technology, Tutor

Wang J (2019) Research on accuracy improvement of tooth shape in thin wall helical ring[D]. Han J, Inner Mongolia University of science and technology, Tutor

García NV, Gonzalo O, Quintana I, Pirling T (2011) Residual stresses and structural changes generated at different steps of the manufacturing of gears: effect of banded. https://doi.org/10.1016/j.msea.2011.03.004

Kang Q (2015) Research on the influence of residual stress on the surface of gear ring based on cutting tool wear[D]. Tutor: Lu JP, Beijing Institute of Technology

Han J, Wang J, Duan RX, Zhang L (2020) Research on the influence law of technological parameters on the cut-ting force of the gear ring gearing shaping. Mach Tool Hydraul. https://doi.org/10.3969/j.issn.1001-3881.2020.17.026

Chang HJ (2018) Research on tool wear and milling parameter optimization in milling 42CrMo die steel [D]. Yanshan University

Huang ZG, Ke YL, Wang LT (2003) Study on related techniques for the finite element method simulation in metal cutting. China Mechan Eng 14(10):846–849

Zheng PT (2020) Calculation of chip thickness and selection of cutting parameters for internal gear shaper. Metalworking Cold Working 3:53–56

Liu YY, Guo JK, Li BT, Hong J, Liu ZG (2019) Error sensitivity analysis and tolerance design of precision machine tools. J Mech Eng 17:145–152

Zorev NN (1963) Inter-relationship between shear processes occurring along tool face and shear plane in metal cutting. Int Res Prod Eng 49:143–152

Zheng PT (2019) Brief analysis of interference and friction of internal gear shaping process with fewer teeth. Tool Technol. https://doi.org/10.3969/j.issn.1000-7008.2019.12.008

Availability of data and material

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

The code for current study is available from the corresponding author on reasonable request.

Funding

The experimental research in this study is supported by Shaoguan Hongda Gear Co., Ltd.

Author information

Authors and Affiliations

Contributions

Xiuxu Zhao: Conceptualization, methodology, data curation, investigation, writing—review and editing. Qingzhuang Liu: Validation, experiment, review and editing. Yu Fu: Writing original draft, visualization, data curation. Peng Chen: Finite element analysis, formal analysis.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, X., Liu, Q., Fu, Y. et al. Study on the influencing factors of the deformation in the process of gear shaping. Int J Adv Manuf Technol 117, 167–185 (2021). https://doi.org/10.1007/s00170-021-07702-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07702-2