Abstract

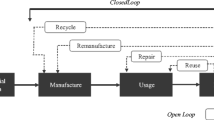

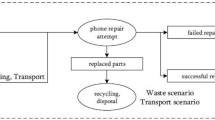

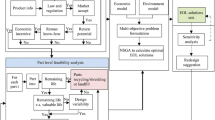

Smartphones are nowadays one of the most used electronic devices in everyday life. They are known to have an average useful lifespan between 18 and 24 months. Indeed, users are led up to dispose of them at the end of their lifespan, and buy last generation smartphones, increasing thus the electronic wastes. To reduce the environmental issues, we propose in this paper to extend the useful lifespan of smartphones based on recovery and remanufacturing options. The developed remanufacturing policies aim to determine the best decisions to ensure the required level of smartphone performances, with the customer profiles and the recovery and remanufacturing center capacity. We propose a new heuristic which constructs a feasible plan for the recovery and the remanufacturing of used smartphones and determines the grade to achieve for each customer, minimising the economic and the environment generated costs.

Similar content being viewed by others

References

Abbey JD, Guide Jr VDR (2018) A typology of remanufacturing in closed-loop supply chains. Int J Prod Res 56(1-2):374–384

Afra AP, Behnamian J (2021) Lagrangian heuristic algorithm for green multi-product production routing problem with reverse logistics and remanufacturing. J Manuf Syst 58:33–43

Alizadeh-Basban N, Taleizadeh AA (2020) A hybrid circular economy-game theoretical approach in a dual-channel green supply chain considering sale’s effort, delivery time, and hybrid remanufacturing. J Clean Prod 250:119,521

Belhadj I, Hammadi M, Aifaoui N (2021) Parallel disassembly approach with recycling rate calculation of industrial products. Int J Adv Manuf Tech 113, 2969–2984

Belhocine L, Dahane M, Yagouni M (2020a) Heuristic based strategy for multi-components products recovery and remanufacturing. In: 2020 5th International conference on logistics operations management (GOL), IEEE, pp 1–6

Belhocine L, Dahane M, Yagouni M (2020b) Performance and usage frequency based policy for products recovery and remanufacturing. In: 2020 7th International conference on control, decision and information technologies (CoDIT), vol 1. IEEE, pp 849–854

Bihouix P (2014) L’Âge des low tech. Vers une civilisation techniquement soutenable: Vers une civilisation techniquement soutenable. Le Seuil

Boudhar H, Dahane M, Rezg N (2017) New dynamic heuristic for the optimization of opportunities to use new and remanufactured spare part in stochastic degradation context. J Intell Manuf 28(2):437–454

CNE (2019) Recycled materials and packaging: state of play, advantages, obstacles, issues and prospects

Cunha JO, Kramer HH, Melo RA (2019) Effective matheuristics for the multi-item capacitated lot-sizing problem with remanufacturing. Comput Oper Res 104:149–158

Fang CC, Lai MH, Huang YS (2017) Production planning of new and remanufacturing products in hybrid production systems. Comput Ind Eng 108:88–99

Fegade V, Shrivatsava R, Kale A (2015) Design for remanufacturing: methods and their approaches. Mater Today Proc 2(4-5):1849–1858

Fu Y, Tian G, Fathollahi-Fard AM, Ahmadi A, Zhang C (2019) Stochastic multi-objective modelling and optimization of an energy-conscious distributed permutation flow shop scheduling problem with the total tardiness constraint. J Cleaner Prod 226:515–525

Godswill AC, Gospel AC, Otuosorochi AI, Somtochukwu IV (2020) Industrial and community waste management: global perspective. Am J Phys Sci 1(1):1–16

Gurita N, Fröhling M, Bongaerts J (2016) Future perspectives for weee recycling—dynamic evaluation of the mobile phones and smartphones waste stream. In: 2016 Electronics goes green 2016+(EGG), IEEE, pp 1–9

Haziri LL, Sundin E (2020) Supporting design for remanufacturing-a framework for implementing information feedback from remanufacturing to product design. Jnl Remanufactur 10, 57–76

Jamwal A, Agrawal R, Sharma M, Kumar V (2020) Review on multi-criteria decision analysis in sustainable manufacturing decision making. Int J Sustain Eng 1–24 https://doi.org/10.1080/19397038.2020.1866708

Kilic OA, Tunc H (2019) Heuristics for the stochastic economic lot sizing problem with remanufacturing under backordering costs. Eur J Oper Res 276(3):880–892

Koken P, Raghavan VA, Yoon SW (2018) A genetic algorithm based heuristic for dynamic lot sizing problem with returns and hybrid products. Comput Ind Eng 119:453–464

Liu J, Zhou Z, Pham DT, Xu W, Yan J, Liu A, Ji C, Liu Q (2018) An improved multi-objective discrete bees algorithm for robotic disassembly line balancing problem in remanufacturing. Int J Adv Manuf Technol 97(9):3937–3962

Liu W, Ma W, Hu Y, Jin M, Li K, Chang X, Yu X (2019) Production planning for stochastic manufacturing/remanufacturing system with demand substitution using a hybrid ant colony system algorithm. J Clean Prod 213:999–1010

Liu Z, Li T, Jiang Q, Zhang H (2014) Life cycle assessment–based comparative evaluation of originally manufactured and remanufactured diesel engines. J Ind Ecol 18(4):567–576

Östlin J, Sundin E, Björkman M (2008) Importance of closed-loop supply chain relationships for product remanufacturing. Int J Prod Econ 115(2):336–348

Ouaret S, Kenné JP, Gharbi A (2019) Production and replacement planning of a deteriorating remanufacturing system in a closed-loop configuration. J Manuf Syst 53:234–248

Quezada F, Gicquel C, Kedad-Sidhoum S, Vu DQ (2020) A multi-stage stochastic integer programming approach for a multi-echelon lot-sizing problem with returns and lost sales. Comput Oper Res 116:104,865

Riisgaard H, Mosgaard M, Zacho KO (2016) Local circles in a circular economy–the case of smartphone repair in denmark. Eur J Sustain Dev 5(1):109–109

Sarkar B, Ullah M, Kim N (2017) Environmental and economic assessment of closed-loop supply chain with remanufacturing and returnable transport items. Comput Ind Eng 111:148–163

Tian G, Zhang H, Feng Y, Jia H, Zhang C, Jiang Z, Li Z, Li P (2017) Operation patterns analysis of automotive components remanufacturing industry development in china. J Clean Prod 164:1363–1375

Tian G, Ren Y, Feng Y, Zhou M, Zhang H, Tan J (2018) Modeling and planning for dual-objective selective disassembly using and/or graph and discrete artificial bee colony. IEEE Trans Industr Inform 15(4):2456–2468

Tigane M, Dahane M, Boudhar M (2019) Multiobjective approach for deteriorating jobs scheduling for a sustainable manufacturing system. Int J Adv Manuf Technol 101(5):1939–1957

Villalba G, Segarra M, Chimenos J, Espiell F (2004) Using the recyclability index of materials as a tool for design for disassembly. Ecol Econ 50(3-4):195–200

Wang W, Tian G, Chen M, Tao F, Zhang C, Abdulraham AA, Li Z, Jiang Z (2020) Dual-objective program and improved artificial bee colony for the optimization of energy-conscious milling parameters subject to multiple constraints. J Clean Prod 245:118,714

Wen H, Hou S, Liu Z, Liu Y (2017) An optimization algorithm for integrated remanufacturing production planning and scheduling system. Chaos Solitons Fractals 105:69–76

Xia X, Zhu H, Zhang Z, Liu X, Wang L, Cao J (2020) 3d-based multi-objective cooperative disassembly sequence planning method for remanufacturing. Int J Adv Manuf Technol 106(9):4611–4622

Yang S, Ong S, Nee A (2016) A decision support tool for product design for remanufacturing. Procedia CIRP 40:144–149

Zhang X, Zhang S, Zhang L, Xue J, Sa R, Liu H (2019) Identification of product’s design characteristics for remanufacturing using failure modes feedback and quality function deployment. J Clean Prod 239:117,967

Zhou L, Gupta SM (2020) Value depreciation factors for new and remanufactured high-technology products: a case study on iphones and ipads. Int J Prod Res 58(23), 7218–7249

Zhou X, Zhao Z, Zhou K, He C (2012) Remanufacturing closed-loop supply chain network design based on genetic particle swarm optimization algorithm. J Cent South Univ 19(2):482–487

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Author contribution

– Latifa Belhocine: formal analysis, original draft writing and programming, validation.

– Mohammed Dahane: conceptualisation, methodology, writing-review and editing, validation.

– Mohammed Yagouni: writing—review and editing, validation.

Availability of data and materials

All the data have been presented in the manuscript.

Consent for participate

The article involves no studies on humans.

Consent for publish

All authors have read and agreed to the published version of the manuscript.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Belhocine, L., Dahane, M. & Yagouni, M. Customer behaviour–based multi-objective approach for the recovery and remanufacturing of used products: application to smartphone reconditioning process. Int J Adv Manuf Technol 117, 125–146 (2021). https://doi.org/10.1007/s00170-021-07646-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07646-7