Abstract

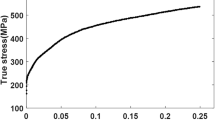

The countersinking process is affected by many factors including the tools and the workpiece parameters. Some forming phenomena such as the knife-edge affect the quality of the countersunk hole. Up to now, many kinds of research rely mainly on experiments which lead to poor quality and difficult control of this process. In this paper, a proposed numerical optimization of the countersinking process is developed to obtain a normalized countersunk hole. This optimization approach is based on the response surface method (RSM), design of experiments (DOE) and sequential quadratic programming (SQP). The finite element model is performed with an elasto-plastic behaviour for simulating the process. A configuration with an imposed displacement applied to the blank holder is adopted in this study. The comparison between the results of the numerical model and the experiments showed a good agreement.

Similar content being viewed by others

References

Chul YP, Alten F (2007) Effect of load transfer on the cracking behaviour at a countersunk fastener hole. Int J Fatigue 29:146–157

Liu J, Kang JX, Yan WZ, Wang FS, Yue ZF (2010) Prediction of fatigue performance of fastener holes with bolt clamping force based on critical plane approach. Mater Sci Eng A, Volume 527:3510–3514

Rana MS, Makabe C, Fujiwara G (2009) The effect of hole shape on the extent of fatigue life improvement by cold expansions. Journal of Engineering Failure Analysis, Volume 16:2081–2090

Darwish F, Gharaibeh M, Tashtoush G (2012) A modified equation for the stress concentration factor in countersunk holes, European Journal of Mechanics A/Solids. 36:94–103

Ray MS, Matthew IR, Frame JW (1998) Metallic fragments on the surface of mini-plates and screws before insertion. Br J Oral Maxillofac Surg 37:14–18

Hassen M, Jallouli I, Krichen A (2017) Advanced analysis for the countersinking process. International Journal of Advanced Manufacturing Technology, Volume 90:3473–3481

Hassen M, Slimen A, Rachid N (2020) Effects of the pre-hole geometry on the final shape of the countersunk hole. International Journal of Advanced Manufacturing Technology, Volume 108:1265–1274

Jallouli I, Krichen A, Bougharriou A, Saï K (2011) Finite element analysis of countersinking process. International Journal of Advanced Manufacturing Technology, Volume 55:641–648

Antoniou A., Lu W.S. (2007) Practical optimization: Algorithms and engineering applications. Springer book.

Breitkopf P, Naceur H, Rassineux A, Villon P (2005) Moving least squares response surface approximation: Formulation and metal forming applications. Journal of Computers and Structures, Volume 83:1411–1428

Hu W, Enying L, Yao LG (2008) Optimization of draw bead design in sheet metal forming based on intelligent sampling by using response surface methodology. Journal of materials processing technology Volume 206:45–55

Hu W, Enying L, Yao LG (2008) Optimization of sheet metal forming processes by adaptive response surface based on intelligent sampling method. Journal of materials processing technology Volume 197:77–88

Zhao H, Gary G (1996) The testing and behaviour modelling of sheet metals at strain rates from 10-4 to 104 s-1. Journal of Materials Science and Engineering, Volume 207:46–50

Alves LM, Nielsen CV, Martins PAF (2011) Revisiting the Fundamentals and Capabilities of the Stack Compression Test. Journal of Experimental Mechanics, Volume 51:1565–1572

Rans C, Straznicky PV (2005) Avoiding knife-edge countersinks in GLARE through dimpling. Journal of Fatigue & Fracture of Engineering Materials and Structures Volume 28:633–640

Connor M, Li W, Fine ME, Achenbach JD (1997) Fatigue crack initiation and growth in riveted specimens: an optical and acoustic microscopic study. International Journal of Fatigue Volume 19:S331–S338

Ohata t., Y. Nakamura Y., Katayama T. E. Nakamachi E. (2003) Development of optimum process design system for sheet fabrication using response surface method. Journal of Materials Processing Technology, Volume 143–144:667–672

Anis BA, Abdelkhalak E (2013) Global sensitivity analysis and multi-objective optimization of loading path in tube hydroforming process based on meta-modelling techniques. Int J Adv Manuf Technol 71:753–773

Author information

Authors and Affiliations

Contributions

This manuscript is truthful original work.

Corresponding author

Ethics declarations

Consent to participate

Informed consent was obtained from all individual participants included in this study.

Consent for publication

All individual participants declare that they accept to submit this paper for publication.

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mosbah, H., Attyaoui, S. & Nasri, R. Optimization of the countersinking parameters based on the response surface method. Int J Adv Manuf Technol 117, 501–510 (2021). https://doi.org/10.1007/s00170-021-07645-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07645-8