Abstract

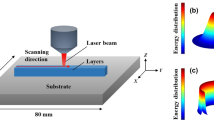

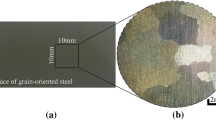

In this paper, we demonstrate the fabrication of S-shaped micron-sized constrictions on steel (Fe3CII) surface using the femtosecond laser ablation technique. The femtosecond laser used has a wavelength of 775 nm, a power range of 0–1000 mW, a pulse duration of 130 fs, and a pulse repetition rate of 1–2 kHz. The ultra-low-pulse duration of 130 fs enables ablation of material surfaces without excessive thermal heating of the material around the zone of ablation. This becomes useful when ablating materials that are thermally sensitive such as superconducting thin films. This practice run of ablating S-shaped micron-sized constrictions on steel surfaces shown in this paper will enable one to use the same technique in ablating micron- and nano-sized structures on superconducting thin films without thermally altering the superconductive film. In this paper, S-shaped micron-sized constrictions on steel were fabricated with a constriction width of 37.1 and 47.3 μm whose images were created using an optical microscope (OM) and S-shaped micron-sized constrictions with a constriction width of 30.8 and 35.2 μm whose images were created using an atomic force microscope (AFM). The reduction in the constriction widths was achieved by reducing the laser ablation width or laser ablation spot size and then bringing the laser ablation spots closer together in G-code program. The reduction of the laser ablation width is achieved by reducing the laser fluence applied closer to the ablation threshold of steel and by using laser beam shaping techniques such as beam collimation and beam focusing.

Similar content being viewed by others

Availability of data and materials

Not applicable.

Abbreviations

- Beam width:

-

Laser ablation width

- L.M.F:

-

Long movement factor

- S.M.F:

-

Short movement factor

- S W :

-

Separation distance between the centers of the laser ablation spots along the length of the steel sample

References

COHERENT Measuring laser power and energy output Available Online: http://www.coherent.com/

Korte F et al (2003) Towards nanostructuring with femtsecond laser pulses. Applied Physics A 77:229–235. https://doi.org/10.1007/s00339-003-2110-z

P. Umenne, Fabrication of nano Josephson junctions using the femtosecond laser technique on high TC superconducting YBa2Cu3O7 thin films, PhD Thesis, University of South Africa 2017 Available Online: http://hdl.handle.net/10500/23646

Umenne P, Srinivasu VV (2017) Femtosecond laser fabrication of micron and sub-micron sized S-shaped contrictions on high TC superconducting YBa2Cu3O7 − x thin films: ablation and lithography issues. J Mater Sci Mater Electron 28:5817–5826. https://doi.org/10.1007/s10854-016-6253-z

Kuznetsov AI, Koch J, Chichkov BN (2009) Nanostructuring of thin gold films by femtosecond lasers. Appl Phys A Mater Sci Process 94:221–230. https://doi.org/10.1007/s00339-008-4859-6

Elkaseh AAO et al (2007) Nanoplough-constrictions on thin YBCO films made with atomic force microscopy. J Nanosci Nanotechnol 7(9):3348–3349. https://doi.org/10.1166/jnn.2007.892

Buttner U, Hardie GL, Rossouw R, Srinivasu VV, Perold WJ (2007) Fabrication of submicron YBCO Josephson junctions by a sample mosaic navigation assisted laser etching process. Supercond Sci Technol 20(11):S426–S429. https://doi.org/10.1088/0953-2048/20/11/S24

van Staden WF et al (2007) A novel buffered high-TC superconducting step-edge Josephson junction. Supercond Sci Technol 20(11):S419–S425. https://doi.org/10.1088/0953-2048/20/11/S23

Du J, Zhang T, Guo YJ, Sun XW (2013) A high-temperature superconducting monolithic microwave integrated Josephson down-converter with high conversion efficiency. Appl Phys Lett 102:212602. https://doi.org/10.1063/1.4808106

Elkaseh AAO, Srinivasu VV, Perold WJ (2009) Observation of Shapiro-steps in AFM-plough micron-size YBCO planar constrictions. IEEE Trans Appl Supercond 19(3):187–190. https://doi.org/10.1109/TASC.2009.2018542

Acknowledgements

I would like to acknowledge the resources and support provided by the University of South Africa in the completion of this project.

Funding

All resources used to generate the data to produce this manuscript were provided by the University of South Africa (UNISA) which whose affiliation is acknowledged in the work.

Author information

Authors and Affiliations

Contributions

I am the sole author of this work and have done the work and experiments, required to collect the data to write the paper.

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable, no humans or animals here involved in this study

Consent for publication

I am the sole author in this publication and give consent to publish.

Competing interests

The author declares no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Umenne, P. Fabrication of S-shaped micron-sized constrictions on FeC (steel) surface using femtosecond laser ablation with beam shaping. Int J Adv Manuf Technol 116, 3043–3050 (2021). https://doi.org/10.1007/s00170-021-07638-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07638-7