Abstract

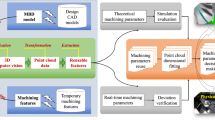

At present, the operators needs to carry out complicated teaching and programming work on the welding path planning for the welding robot before welding the steel mesh. In this work, an automatic welding path planning method of steel mesh based on point cloud is proposed to simplify the complicated teaching and programming work in welding path planning. The point cloud model of steel mesh is obtained by three-dimensional vision structured light camera. Then, we use the relevant point cloud processing algorithm to calculate the welding path of the steel mesh, and obtain the 3D information of the welding path for the welding localization of the robot welding process. Experimental results show that the method can accurately realize the welding path planning of the steel mesh and accomplish the welding task without teaching and programming before welding, which improves the production efficiency.

Similar content being viewed by others

References

Zhu J, Wang J, Su N, Xu G, Yang M (2017) An infrared visual sensing detection approach for swing arc narrow gap weld deviation. J Mater Process Technol 243:258–268

Rodriguez-Martin M, Rodriguez-Gonzalvez P, Gonzalez-Aguilera D, Fernandez-Hernandez J (2017) Feasibility study of a structured light system applied to welding inspection based on articulated coordinate measure machine data. IEEE Sensors J 48:4217–4224

Ahmed SM, Tan YZ, Lee GH, Chew CM, Pang CK (2016) Object detection and motion planning for automated welding of tubular joints. In: 2016 IEEE/RSJ international conference on intelligent robots and systems (IROS). IEEE, pp 2610–2615

Li Y, Li YF, Wang QL, Xu D, Min T (2010) Measurement and defect detection of the weld bead based on online vision inspection. IEEE Trans Instrum Meas 59:1841–1849

Liu Y, Zhang Y (2010) Iterative local anfis-based human welder intelligence modeling and control in pipe gtaw process: a data-driven approach. IEEE/ASME Trans Mechatron 20:1079–1088

Wang LM, Yin Y, Yan XL (2020) The application research of welding line distin-guish method based on v structure laser line. In: 2020 international conference on artificial intelligence and electromechanical automation (AIEA). IEEE, pp 57–62

Xu YL, Yu HW, Zhong JY, Lin T, Chen SB (2012) Real-time seam tracking control technology during welding robot GTAW process based on passive vision sensor. J Mater Process Technol 212:1654–1662

Zeng JL, Chang BH, Du D, Peng GD, Shan JG (2017) A vision-aided 3D path teaching method before narrow butt joint welding. Sensors 17:1099–1114

Hou Z, Xu YL, Xiao RQ, Chen SB (2020) A teaching-free welding method based on laser visual sensing system in robotic GMAW. Int J Adv Manuf Technol 109:1755–1774

Yang L, Li E, Long T, Fan JF, Liang ZZ (2018) A novel 3-D path extraction method for arc welding robot based on stereo structured light sensor. IEEE Sensors J 19:763–773

Zhang LZ, Xu YL, Du SF, Zhao WJ, Hou Z, Chen SB (2018) Point cloud based three-dimensional reconstruction and identification of initial welding position. Trans Intell Weld Manuf 1:61–77

Yang L, Liu YH, Peng JZ, Liang ZZ (2020) A novel system for off-line 3D seam extraction and path planning based on point cloud segmentation for arc welding robot. Robot Comput Integr Manuf: 64

Yu JP, Shi P, Chen XK, Cui GZ (2020) Finite-time command filtered adaptive control for nonlinear systems via immersion and invariance, Science China information sciences

Fu C, Wang QG, Yu JP, Lin C (2020) Neural network-based finite-time command filtering control for switched nonlinear systems with backlash-like hysteresis. Int J Adv Manuf Technol 99:1–6

Yang L, Liu YH, Peng JZ (2020) Advances techniques of the structured light sensing in intelligent welding robots: a review. Int J Adv Manuf Technol 110:1027–1046

Wang XF, Zhang XQ, Ren XK, Li LF, Feng HJ (2020) Point cloud 3D parent surface reconstruction and weld seam feature extraction for robotic grinding path planning. Int J Adv Manuf Technol 107:827–841

Wang NF, Zhong KF, Shi XD, Zhang XM (2020) A robust weld seam recognition method under heavy noise based on structured-light vision. Robot Comput Integr Manuf: 61

Yu JP, Shi P, Liu JP, Lin C (2020) Neuroadaptive finite-time control for nonlinear MIMO systems with input constraint. IEEE Trans Cybern 99:1–6

Lei T, Huang Y, Shao WJ, Liu WN, Rong YM (2020) A tactual weld seam tracking method in super narrow gap of thick plates. Robot Comput Integr Manuf: 62

Wu KX, Wang TQ, He JJ, Liu Y, Jia ZW (2020) Autonomous seam recognition and feature extraction for multi-pass welding based on laser stripe edge guidance network. Int J Adv Manuf Technol 111:2719–2731

Dong ZX, Mai ZH, Yin SQ, Wang J, Yuan J, Fei YN (2020) A weld line detection robot based on structure light for automatic NDT. Int J Adv Manuf Technol 111:1831–1845

Du RQ, Xu YL, Yin SQ, Hou Z, Shu J, Chen SB (2019) Strong noise image processing for vision-based seam tracking in robotic gas metal arc welding. Int J Adv Manuf Technol 101:2135–2149

Funding

The authors gratefully thank the research funding from the Shandong Provincial Key Research and Development Program (Major Scientific and Technological Innovation Project) under Grant No. 2019JZZY010441.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Author contribution

Yusen Geng was a major contributor in writing the manuscript. All authors read and approved the final manuscript.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Geng, Y., Zhang, Y., Tian, X. et al. A method of welding path planning of steel mesh based on point cloud for welding robot. Int J Adv Manuf Technol 116, 2943–2957 (2021). https://doi.org/10.1007/s00170-021-07601-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07601-6