Abstract

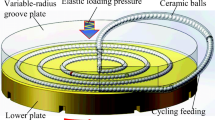

Ceramic balls are produced via powder metallurgy and compared to steel balls are preferred due to their special physical and mechanical properties. Ceramic balls can reach the desired surface finishing, sphericity, and diameter by finishing processes such as grinding, lapping, and polishing. By considering the length of time and high costs of the finishing process, creating an economic mechanism is of great importance in the use of ceramic balls. The present paper was conducted to investigate the eccentric lapping plates mechanism with eccentric V-grooves for ceramic balls lapping. This mechanism is proposed to increase the material removal rate (MRR) and to reduce the sphericity error of the ceramic balls. The effects of parameters including lower and upper lapping plate rotation speeds, the eccentricity of lapping plates, and lapping force were investigated on MRR, and the reduction of sphericity error. The kinematic analysis was performed to calculate the trajectory length and its distribution on the ball surface. Experimental tests were carried out to validate the kinematic analysis on the pre-sintered Al2O3 balls. The effects of the above-mentioned parameters on the lapping process were determined. The proposed mechanism provided an MRR of 0.766 mm/h; in this regard, sphericity error also reduced down 0.184 mm in 20 min.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

- A i :

-

Number of the points in area i

- \( {\overline{A}}_i \) :

-

Average number of the points in all the areas of the ball surface

- E:

-

Eccentricity of the groove from the axis of rotation of the lower lapping plate

- e:

-

Distance between the axis of rotation of the upper and lower lapping plates

- i:

-

The calculation step

- L:

-

Trajectory length

- N :

-

Number of areas of the ball surface

- RA :

-

The distance between contact point A to the center of the V-groove

- RB :

-

The distance between contact point B to the center of the V-groove

- R g :

-

Radius of the V-groove

- R b :

-

Radius of the ball

- r A :

-

The distance from the center of the lower lapping plate to the contact point A of the ball

- r B :

-

The distance from the center of the lower lapping plate to the contact point B of the ball

- r u :

-

The distance from the center of the upper lapping plate to the center of the ball

- r g :

-

The distance between the center of rotation of the lower lapping plate and the point of contact of the ball with the upper lapping plate

- t :

-

Time

- ω b :

-

Ball spin speed

- ω c :

-

Ball circulation speed

- β:

-

Spin angle

- γ :

-

The angle between the linear velocity direction of the lower lapping plate and the direction of motion of the ball in the V-groove

- ∆θ:

-

The ball’s rotation increment in each calculation step

- θ:

-

Half of the V-groove angle

- τ:

-

Angle between the linear velocity vector of the upper lapping plate at the contact point of the ball with the direction of motion of the ball

- ∅:

-

The angle between the linear velocity direction of the lower lapping plate and the direction of motion of the ball in the V-groove

- ΩL :

-

The lower lapping plate speed

- Ωu :

-

The upper lapping plate speed

References

Otitoju TA, Okoye PU, Chen G, Li Y, Okoye MO, Li S (2020) Advanced ceramic components: materials, fabrication, and applications. J Ind Eng Chem 85:34–65

Sunanta O (2002) Flat surface lapping: process modeling in an intelligent environment. Doctoral dissertation, University of Pittsburgh

Alavijeh MS, Amirabadi H (2019) Investigation and optimization of the internal cylindrical surface lapping process of 440c steel. J Mech Sci Technol 33(8):3933–3941

London CL (1990) U.S. Patent No. 4,965,967. Washington, DC: U.S. Patent and Trademark Office

Kurobe T, Morita T, Tsuchihashi N (2004) Super fine finishing ceramic ball using spin angle controlled machining method. J Jpn Soc Precis Eng 70:1392–1396

Kang J, Hadfield M (1970) A study on the lapping of ceramic balls. WIT Transactions on Engineering Sciences, 25.

Zhang B, Nakajima A (2000) Spherical surface generation mechanism in the grinding of balls for ultraprecision ball bearings. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 214(4):351–357

Zhou F, Yuan J, Lyu B, Yao W, Zhao P (2016) Kinematics and trajectory in processing precision balls with eccentric plate and variable-radius V-groove. Int J Adv Manuf Technol 84(9):2167–2178

Zhou F, Yao W, Yuan J, Li F, Lyu B, Zhao P (2020) Establishment of material removal model for lapping ceramic balls with variable-radius groove plate. Int J Adv Manuf Technol 111(9):2577–2587

Feng M, Wu Y, Yuan J, Ping Z (2017) Processing of high-precision ceramic balls with a spiral V-groove plate. Front Mech Eng 12(1):132–142

Pasichnyi O (2019) Technology precision machining of ceramic balls in the V-grooves of variable curvature. In Simulation and Experiments of Material-Oriented Ultra-Precision Machining. Springer, Singapore, pp 237–264

Xiao XL, Li GX, Mei HJ, Yan QS, Lin HT, Zhang FL (2020) Polishing of silicon nitride ceramic balls by clustered magnetorheological finish. Micromachines 11(3):304

Lee RT, Hwang YC, Chiou YC (2006) Lapping of ultra-precision ball surfaces. Part I. Concentric V-groove lapping system. Int J Mach Tools Manuf 46(10):1146–1156

Kang J, Hadfield M (2001) A novel eccentric lapping machine for finishing advanced ceramic balls. Proc Inst Mech Eng B J Eng Manuf 215(6):781–795

Lee RT, Hwang YC, Chiou YC (2006) Lapping of ultra-precision ball surfaces. Part II. Eccentric V-groove lapping system. Int J Mach Tools Manuf 46(10):1157–1169

Barylski A, Piotrowski N (2019) Non-conventional approach in single-sided lapping process: kinematic analysis and parameters optimization. Int J Adv Manuf Technol 100(1-4):589–598

Author information

Authors and Affiliations

Contributions

Mohammad Reza Darmiyani: conceptualization, methodology, formal analysis, investigation, writing, original draft.

Hossein Amirabadi: conceptualization, methodology, supervision, writing, review, editing.

Mohammad Khosravi: supervision, writing, review, editing. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval

The authors understand and approve the ethical responsibilities of the authors.

Consent to participate

The authors consent to participate.

Consent for publication

We the authors, Mohammad Reza Darmiyani, Dr. Hossein Amirabadi and Dr. Mohammad Khosravi, consent and approve the publication of this article with identification number JAMT-D-21-00499.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Darmiyani, M.R., Amirabadi, H. & Khosravi, M. Theoretical and experimental study of ceramic balls lapping with eccentric plates and eccentric V-groove. Int J Adv Manuf Technol 116, 3417–3430 (2021). https://doi.org/10.1007/s00170-021-07585-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07585-3