Abstract

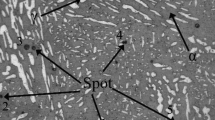

In the present work, the interface morphology and the evolution of nitride precipitates in LDX 2101 stainless steel isothermally treated at 750 °C for various aging times were investigated. The microstructure results showed that the Cr2N nitrides precipitated along the δ/γ interface with 200 nm in length and continue to grow to 2 μm after 240 h of aging. However, only Cr2N nitrides were found at the δ/δ interface after long term of aging. Atomic force microscopy (AFM) analysis revealed that Cr2N nitrides and Cr23C6 carbides started to precipitate after the first 10 min of aging with a small needle shape of the former and specific triangular morphology of the latter. The evolution of hardness and Young’s modulus of the interfaces, performed with nano-indentation measurements, showed that the δ/γ interface became harder (4.1 ± 0.2 GPa) with increasing aging times, whereas negligible changes in the hardness and elastic modulus were recorded at the δ/δ interface. 3D topographic analysis of the immersed surfaces revealed that the susceptibility of δ phase to preferential dissolution in 3.5% NaCl solution increased with aging time. This behavior was manifested by the important imperfections of δ phase, the high surface roughness (55.7 nm), and the deep corrosion pits (30 nm) along the δ/γ interface and around the Cr2N nitrides.

Similar content being viewed by others

Availability of data and material

The authors confirm that the data supporting the findings of this study are available within the article. The raw data that support the findings of this study are available upon reasonable request.

Code availability

Not applicable.

References

Tehovnik F, Batič BŠ, Vode F et al (2018) Nitrides and carbides in 2101 lean duplex stainless steel. Mater Tehnol 52:821–826. https://doi.org/10.17222/mit.2018.145

Ran Q, Xu Y, Li J, Wan J, Xiao X, Yu H, Jiang L (2014) Effect of heat treatment on transformation-induced plasticity of economical Cr19 duplex stainless steel. Mater Des 56:959–965. https://doi.org/10.1016/j.matdes.2013.12.019

Choi JY, Ji JH, Hwang SW, Park KT (2012) TRIP aided deformation of a near-Ni-free, Mn-N bearing duplex stainless steel. Mater Sci Eng A 535:32–39. https://doi.org/10.1016/j.msea.2011.12.037

Breda M, Pellizzari M, Frigo M (2015) σ-Phase in lean duplex stainless steel sheets. Acta Metall Sin (Engl Lett) 28:331–337. https://doi.org/10.1007/s40195-014-0201-9

Silva R, Baroni LFS, Silva MBR, Afonso CRM, Kuri SE, Rovere CAD (2016) Effect of thermal aging at 475 ° C on the properties of lean duplex stainless steel 2101. Mater Charact 114:211–217. https://doi.org/10.1016/j.matchar.2016.03.002

Calliari I, Pellizzari M, Zanellato M, Ramous E (2011) The phase stability in Cr-Ni and Cr-Mn duplex stainless steels. J Mater Sci 46:6916–6924. https://doi.org/10.1007/s10853-011-5657-7

Liljas M, Johansson P, Liu H-P, Olsson C-OA (2008) Development of a lean duplex stainless steel. Steel Res Int 79:466–473. https://doi.org/10.1002/srin.200806154

Maetz J, Cazottes S, Verdu C, Kleber X (2015) Precipitation and phase transformations in 2101 lean duplex stainless steel during isothermal aging. Metall Mater Trans A 47:239–253. https://doi.org/10.1007/s11661-015-3215-7

Lee KM, Cho H, Choi DC (1999) Effect of isothermal treatment of SAF 2205 duplex stainless steel on migration of δ/γ interface boundary and growth of austenite. J Alloys Compd 285:156–161. https://doi.org/10.1016/S0925-8388(99)00014-6

Zhang W, Jiang LZ, Gao JQ, Song HM, Hu JC (2010) Study of precipitation in 2101 duplex stainless steel. Mater Sci Technol 26:515–521. https://doi.org/10.1179/174328409X405689

Zelinka SL, Ortiz-candelaria L, Rammer DR (2009) Electrochemical impedance spectroscopy (EIS) as a tool for measuring corrosion of polymer-coated fasteners used in treated wood. For Prod J 59:77–82

Ze W, Jianxin D, Youqiang X et al (2012) Effect of surface texturing on friction properties of WC / Co cemented carbide. Mater Des 41:142–149. https://doi.org/10.1016/j.matdes.2012.05.012

Ouali N, Khenfer K, Belkessa B, Fajoui J, Cheniti B, Idir B, Branchu S (2019) Effect of heat input on microstructure, residual stress, and corrosion resistance of UNS 32101 lean duplex stainless steel weld joints. J Mater Eng Perform 28:4252–4264. https://doi.org/10.1007/s11665-019-04194-w

Ahn S, Kang S (2000) Formation of core / rim structures in Ti ( C , N ) -WC-Ni cermets via a dissolution and pricipitation process. J Am Ceram Soc 83:1489–1494. https://doi.org/10.1111/j.1151-2916.2000.tb01415.x

Sieurin H, Sandström R, Westin EM (2006) Fracture toughness of the lean duplex stainless steel LDX 2101. Metall Mater Trans A Phys Metall Mater Sci 37:2975–2981. https://doi.org/10.1007/s11661-006-0179-7

Atapour M, Sarlak H, Esmailzadeh M (2016) Pitting corrosion susceptibility of friction stir welded lean duplex stainless steel joints. Int J Adv Manuf Technol 83:721–728. https://doi.org/10.1007/s00170-015-7601-5

Sathirachinda N, Pettersson R, Wessman S, Pan J (2010) Study of nobility of chromium nitrides in isothermally aged duplex stainless steels by using SKPFM and SEM/EDS. Corros Sci 52:179–186. https://doi.org/10.1016/j.corsci.2009.08.057

Nilsson JO, Wilson A (1993) Influence of isothermal phase transformations on toughness and pitting corrosion of super duplex stainless steel SAF 2507. Mater Sci Technol (UK) 9:545–554. https://doi.org/10.1179/mst.1993.9.7.545

Wei Z, Laizhu J, Jincheng H, Hongmei S (2009) Effect of ageing on precipitation and impact energy of 2101 economical duplex stainless steel. Mater Charact 60:50–55. https://doi.org/10.1016/j.matchar.2008.07.002

Maamache B, Cheniti B, Belkessa B, Tahar-chaouch K, Kouba R (2021) Effect of aging temperature on the microstructure, local mechanical properties, and wear behavior of a UNS S32750 super duplex stainless steel. J Mater Eng Perform 30:546–555. https://doi.org/10.1007/s11665-020-05332-5

Zhang Z, Zhao H, Zhang H, Yu Z, Hu J, He L, Li J (2015) Effect of isothermal aging on the pitting corrosion resistance of UNS S82441 duplex stainless steel based on electrochemical detection. Corros Sci 93:120–125. https://doi.org/10.1016/j.corsci.2015.01.014

Sathirachinda N, Pettersson R, Wessman S, Kivisäkk U, Pan J (2011) Electrochimica Acta Scanning Kelvin probe force microscopy study of chromium nitrides in 2507 super duplex stainless steel — implications and limitations. Electrochim Acta 56:1792–1798. https://doi.org/10.1016/j.electacta.2010.08.038

Deng B, Wang Z, Jiang Y, Wang H, Gao J, Li J (2009) Evaluation of localized corrosion in duplex stainless steel aged at 850 ° C with critical pitting temperature measurement. Electrochim Acta 54:2790–2794. https://doi.org/10.1016/j.electacta.2008.11.038

Deng B, Jiang YM, Gao J, Li J (2010) Effect of annealing treatment on microstructure evolution and the associated corrosion behavior of a super-duplex stainless steel. J Alloys Compd 493:461–464. https://doi.org/10.1016/j.jallcom.2009.12.127

Garfias-Mesias LF, Sykes JM, Tuck CDS (1996) The effect of phase compositions on the pitting corrosion of 25 Cr duplex stainless steel in chloride solutions. Corros Sci 38:1319–1330

Perren RA, Suter T, Solenthaler C, Gullo G, Uggowitzer PJ, Böhni H, Speidel MO (2001) Corrosion resistance of super duplex stainless steels in chloride ion containing environments: investigations by means of a new microelectrochemical method. II. Influence of precipitates. Corros Sci 43:727–745. https://doi.org/10.1016/S0010-938X(00)00088-3

Ha HY, Kwon HS (2007) Effects of Cr2N on the pitting corrosion of high nitrogen stainless steels. Electrochim Acta 52:2175–2180. https://doi.org/10.1016/j.electacta.2006.08.034

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Zhao Y, Wang Y, Li X, Zhang W, Tang S, Liu Z (2018) Effects of plastic straining on the corrosion resistance of TRIP-aided lean duplex stainless steels. J Mater Sci 53:9258–9272. https://doi.org/10.1007/s10853-018-2196-5

Zhang L, Zhang W, Jiang Y, Deng B, Sun D, Li J (2009) Electrochimica Acta Influence of annealing treatment on the corrosion resistance of lean duplex stainless steel 2101. Electrochim Acta 54:5387–5392. https://doi.org/10.1016/j.electacta.2009.04.023

Chan KW, Tjong SC (2014) Effect of secondary phase precipitation on the corrosion behavior of duplex stainless steels. Materials 7:5268–5304. https://doi.org/10.3390/ma7075268

Simmons JW (1996) Overview: High-nitrogen alloying of stainless steels. Mater Sci Eng A 207:159–169. https://doi.org/10.1016/0921-5093(95)09991-3

Deng B, Jiang Y, Xu J, Sun T, Gao J, Zhang L, Zhang W, Li J (2010) Application of the modified electrochemical potentiodynamic reactivation method to detect susceptibility to intergranular corrosion of a newly developed lean duplex stainless steel LDX2101. Corros Sci 52:969–977. https://doi.org/10.1016/j.corsci.2009.11.020

Maetz JY, Douillard T, Cazottes S, Verdu C, Kléber X (2016) M23C6 carbides and Cr2N nitrides in aged duplex stainless steel: a SEM, TEM and FIB tomography investigation. Micron 84:43–53. https://doi.org/10.1016/j.micron.2016.01.007

Hong HU, Rho BS, Nam SW (2001) Correlation of the M23C6 precipitation morphology with grain boundary characteristics in austenitic stainless steel. Mater Sci Eng A 318:285–292. https://doi.org/10.1016/S0921-5093(01)01254-0

Silva IC, Rebello JMA, Bruno AC et al (2008) Structural and magnetic characterization of a carburized cast austenitic steel. Scr Mater 59:1010–1013. https://doi.org/10.1016/j.scriptamat.2008.07.015

Stevens KJ, Parbhu A, Soltis J, Stewart D (2003) Magnetic force microscopy of a carburized ethylene pyrolysis tube. J Phys D Appl Phys 36:164–168. https://doi.org/10.1088/0022-3727/36/2/315

Zhao Y, Zhang W, Liu Z, Wang G (2017) Development of an easy-deformable Cr21 lean duplex stainless steel and the effect of heat treatment on its deformation mechanism. Mater Sci Eng A 702:279–288. https://doi.org/10.1016/j.msea.2017.07.020

Fang YL, Liu ZY, Xue WY, Song HM, Jiang LZ (2010) Precipitation of secondary phases in lean duplex stainless steel 2101 during isothermal ageing. ISIJ Int 50:286–293. https://doi.org/10.2355/isijinternational.50.286

Guo LQ, Li M, Shi XL, Yan Y, Li XY, Qiao LJ (2011) Effect of annealing temperature on the corrosion behavior of duplex stainless steel studied by in situ techniques. Corros Sci 53:3733–3741. https://doi.org/10.1016/j.corsci.2011.07.019

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

This study complies with the ethical standards set out by Springer. All the authors read and approved the final manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ouali, N., Cheniti, B., Belkessa, B. et al. Influence of isothermal aging in LDX 2101 duplex stainless steel on the microstructure and local properties. Int J Adv Manuf Technol 116, 1881–1893 (2021). https://doi.org/10.1007/s00170-021-07515-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07515-3