Abstract

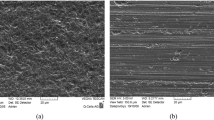

The quality and efficiency of slicing will be reduced if the abrasives on the surface of a diamond wire saw shed in sawing. Generally, the diamond abrasives are held on the surface of an electroplated diamond wire saw by a nickel-plated layer. The abrasive retention state, reflecting abrasive shedding, can be characterized by the plastic deformation of the plating layer at the interface between the nickel-plated layer and the abrasive. To gain an in-depth understanding of the abrasive shedding mechanism, a finite element model that the double-cone diamond abrasive is embedded in a nickel-plated layer was established based on the mechanical properties test of the nickel-plated layer in this paper to research the effects of the residual stress and hardness of the nickel-plated layer as well as the protrusion height of the diamond abrasive on the abrasive retention capacity. The results show that the residual stress on the surface layer of the nickel-plated layer was compressive stress. The abrasive retention capacity was increased with the increase of the hardness or the decrease of the residual compressive stress of the nickel-plated layer. For the same diamond abrasive, it was decreased with the increase of the protrusion height of the abrasive. Based on the results of the finite element analysis, a calculation procedure of abrasive shedding rate was presented. Subsequently, the slicing experiment of a single crystal silicon rod was carried out by the Meyer Burger RTD6800 multi-wire sawing machine and the electroplated diamond wire saw with a core wire diameter of 65μm. The abrasive shedding rate of the diamond wire saw caused by sawing was analyzed theoretically and experimentally. The research work is of great significance to improve the quality detection and evaluation of an electroplated diamond wire saw.

Similar content being viewed by others

References

Yu X, Wang P, Li X, Yang D (2012) Thin Czochralski silicon solar cells based on diamond wire sawing technology. Sol Energy Mater Sol Cells 98:337–342. https://doi.org/10.1016/j.solmat.2011.11.028

Gao Y, Ge P, Zhang L, Bi W (2019) Material removal and surface generation mechanisms in diamond wire sawing of silicon crystal. Mater Sci Semicond Process 103:104642. https://doi.org/10.1016/j.mssp.2019.104642

Huang H, Wang S, Xu X (2017) Effect of wire vibration on the materials loss in sapphire slicing with the fixed diamond wire. Mater Sci Semicond Process 71:93–101. https://doi.org/10.1016/j.mssp.2017.07.010

Li X, Gao Y, Yin Y, Wang L, Pu T (2020) Experiment and theoretical prediction for surface roughness of PV polycrystalline silicon wafer in electroplated diamond wire sawing. J Manuf Process 49:82–93. https://doi.org/10.1016/j.jmapro.2019.11.022

Li H, Gao Y, Ge P, Bi W, Zhang L (2020) Study on process parameters of fabrication fine diameter electroplated diamond wire for slicing crystalline silicon solar cell. Int J Adv Manuf Technol 106:3153–3175. https://doi.org/10.1007/s00170-019-04860-2

Scott PM, Nicholas M, Dewar B (1975) The wetting and bonding of diamonds by copper-base binary alloys. J Mater Sci 10:1833–1840. https://doi.org/10.1007/BF00754470

Levin E, Gutmanas EY (1990) Solid-state bonding of diamond to Nichrome and Co-20wt% W alloys. J Mater Sci Lett 9:726–730. https://doi.org/10.1007/BF00721815

Romanski A, Lachowski J, Konstanty J (2006) Diamond retention capacity: evaluation of stress field generated in a matrix by a diamond crystal. Ind Diam Rev 66:43–45 https://www.researchgate.net/publication/275956460

Zhao X, Duan L, Chikhotkin VF, Weng H (2015) Summary on holding force of metallic matrix to diamond. Diam Abras Eng 35:41–46, 50. https://doi.org/10.13394/j.cnki.jgszz.2015.6.0009

Webb SW (1999) Diamond retention in sintered cobalt bonds for stone cutting and drilling. Diam Relat Mater 8:2043–2052. https://doi.org/10.1016/S0925-9635(99)00167-3

Xu J, Sheikh AH, Xu C (2017) 3-D finite element modelling of diamond pull-out failure in impregnated diamond bits. Diam Relat Mater 71:1–12. https://doi.org/10.1016/j.diamond.2016.11.006

Konstanty J, Romanski A (2014) Numerical analysis of diamond retention in cobalt and a copper-base alloy. Arch Metall Mater 59:1457–1462. https://doi.org/10.2478/amm-2014-0247

Noyan IC, Cohen JB (1987) Residual stress-measurement by diffraction and interpretation. Springer-Verlag Inc, New York

Tekkaya EA (2001) Improved relationship between Vickers hardness and yield stress for cold formed materials. Steel Res 72:304–310. https://doi.org/10.1002/srin.200100122

Mahmoud T, Tamaki J, Yan J (2003) Three-dimensional shape modeling of diamond abrasive grains measured by a scanning laser microscope. Key Eng Mater 238-239:131–136. https://doi.org/10.4028/www.scientific.net/kem.238-239.131

Ge M, Wang P, Bi W, Ge P (2021) Fabrication of thin resin-bonded diamond wire and its application to ductile-mode wire sawing of mono-crystalline silicon. Mater Sci Semicond Process 126:105665. https://doi.org/10.1016/j.mssp.2021.105665

Hadian SE, Gabe DR (1999) Residual stresses in electrodeposits of nickel and nickel-iron alloys. Surf Coat Technol 122:118–135. https://doi.org/10.1016/S0257-8972(99)00328-X

Wang P, Ge P, Gao Y, Bi W (2017) Prediction of sawing force for single-crystal silicon carbide with fixed abrasive diamond wire saw. Mater Sci Semicond Process 63:25–32. https://doi.org/10.1016/j.mssp.2017.01.014

Chen S, Liu L, Liu P, Ma J, Chen G (2009) Theoretical and experimental study on relationship between stress-strain and temperature variation. Sci China Ser D-Earth Sci 52(11):1825–1834. https://doi.org/10.1007/s11430-009-0183-z

Chen J, Mu D, Liao X, Huang G, Huang H, Xu X, Huang H (2018) Interfacial microstructure and mechanical properties of synthetic diamond brazed by Ni-Cr-P filler alloy. Int J Refract Met Hard Mater 74:52–60. https://doi.org/10.1016/j.ijrmhm.2018.03.005

Liu T, Ge P, Gao Y, Bi W (2017) Depth of cut for single abrasive and cutting force in resin bonded diamond wire sawing. Int J Adv Manuf Technol 88:1763–1773. https://doi.org/10.1007/s00170-016-8896-6

Chung C, Tsay GD, Tsai MH (2014) Distribution of diamond grains in fixed abrasive wire sawing process. Int J Adv Manuf Technol 73(9-12):1485–1494. https://doi.org/10.1007/s00170-014-5782-y

Lin Z, Huang H, Xu X (2019) Experimental and simulational investigation of wire bow deflection in single wire saw. Int J Adv Manuf Technol 101:687–695. https://doi.org/10.1007/s00170-018-2919-4

Zhu L, Kao I (2005) Galerkin-based modal analysis on the vibration of wire-slurry system in wafer slicing using a wiresaw. J Sound Vib 283:589–620. https://doi.org/10.1016/j.jsv.2004.04.018

Meißner D, Schoenfelder S, Hurka B, Zeh J, Sunder K, Koepge R, Wagner T, Grün A, Hagel HJ, Moeller HJ, Schwabe H, Anspach O (2014) Loss of wire tension in the wire web during the slurry based multi wire sawing process. Sol Energy Mater Sol Cells 120:346–355. https://doi.org/10.1016/j.solmat.2013.05.047

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

Funding

This work was supported by the National Natural Science Foundation of China (No.51775317); and the Key Research and Development Program of Shandong Province (No.2019JZZY020209).

Author information

Authors and Affiliations

Contributions

Jintao Zheng: writing — original draft, writing — review and editing, investigation, methodology. Qian Xie: writing — original draft, numerical simulations. Peiqi Ge: conceptualization, funding acquisition, project administration, supervision. Jianfeng Meng: methodology, software and editing. Wenbo Bi: formal analysis, validation and experiment.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

The consent to submit this paper has been received explicitly from all co-authors.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, J., Xie, Q., Ge, P. et al. Study on the abrasive retention capacity on the surface of electroplated diamond wire saw. Int J Adv Manuf Technol 116, 747–758 (2021). https://doi.org/10.1007/s00170-021-07476-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07476-7