Abstract

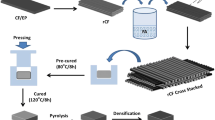

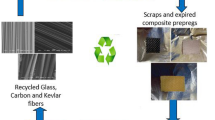

Recycled carbon fiber (RCF) can be used in fused deposition modeling (FDM), which can not only improve the reuse value of carbon fiber but also make up for the insufficient performance of general FDM products. According to the recycling principle, the device special for carbon fiber-reinforced resin matrix composite (CFRP) recycling is developed; soft and fluffy carbon fibers were obtained under the optimal process parameters in this work. RCF was remanufactured into composites by grinding, extrusion, and FDM. The microtopography and monofilament tensile strength of RCF were analyzed, the particle size distribution of chopped RCF and the interface combination in composites were observed, and the mechanical properties of RCF-reinforced polylactic acid (PLA) composites (RCF/PLA) were studied. Results show that the monofilament tensile strength of RCF obtained under the optimal process parameters was 8% higher than that of original carbon fiber (OCF). Compared with PLA, the tensile strength of OCF-reinforced PLA composites (OCF/PLA) and RCF/PLA composites was reduced by 25% and 12.5%, respectively. The chemical bonding between RCF and resin matrix and the nozzle temperature, layer height, and printing speed in FDM process have an important influence on the tensile strength of the composites. Compared with that of PLA, the bending strength of OCF/PLA composites increased by about 7.8%, the flexural modulus increased by about 81%, the bending strength of RCF/PLA composites increased by 10.4%, and the flexural modulus increased by 87%. Through FDM, RCF can be used to enhance the resin matrix with higher requirements for stiffness, bending strength, and wear resistance.

Similar content being viewed by others

Availability of data and material

All data generated or analyzed during this study can be included in this published article. The experimental data in this article can be used for scientific research, teaching, etc.

Code availability

Not applicable

References

Xing LY, Feng ZH, Bao JW, Li SM (2020) Opportunities and challenges facing the development of carbon fiber and resin matrix composites industry. Acta Materiae Compositae Sinica 37:2700–2706

Tsuchida A (2016) High-performance and specialty fibers: concepts, technology and modern applications of man-made fibers for the future. Springer, New York

Yang B (2018) Current situation and prospect of carbon fiber industry development and recycling technology. the first Composite Recycling International Forum and the inaugural meeting of the Chapter, BeiJing, China

Ajam A, Bagha A, Mustapha S, Harb M (2020) Zero-waste recycling of shelf-cured pre-impregnated carbon fiber reinforced epoxy laminae. Appl Compos Mater 27:357–373. https://doi.org/10.1007/s10443-020-09821-7

Jeong JS, Kim KW, An KH, Kim BJ (2019) Fast recovery process of carbon fibers from waste carbon fibers-reinforced thermoset plastics. J Environ Manag 247:816–821

Mazzocchetti L, Benelli T, D’Angelo E, Leonardi C, Zattini G, Giorgini L (2018) Validation of carbon fibers recycling by pyro-gasification: the influence of oxidation conditions to obtain clean fibers and promote fiber/matrix adhesion in epoxy composites. Compos Part A-Appl S 112:504–514

Yang J, Lin J, Liu WB, Wang J, Tang T (2015) Recycling of carbon fibre reinforced epoxy resin composites under various oxygen concentrations in nitrogen–oxygen atmosphere. J Anal Appl Pyrolysis 112:253–261

Yatim NM, Shamsudin Z, Shaaban A, Ghafar JA, Khan MJH (2020) Recovery of carbon fiber from carbon fiber reinforced polymer waste via pyrolysis. Int J Adv Manuf Technol 14(1):37–47

Huang YF, Ge ZX, Zhao CJ, Dong JB, Shitian M, Ma WF, Wang GF, Qian XZ (2015) Solvothermal recovery of carbon fibers from thermoset polymer-based carbon fiber reinforced polymers. J Reinf Plast Compos 34(20):1673–1683

Kim KW, Lee HM, An JH (2017) Recycling and characterization of carbon fibers from carbon fiber reinforced epoxy matrix composites by a novel super-heated-steam method. J Environ Sci Manag 203:872–879

Qian Z, Ma ZY, Shi GT, Wang QF, Xu WK (2019) Mechanical properties of PLA/CF composite extruded 3D printed. Engineering Plastics Application 47:59–62

Gupta A, Fidan I, Hasanov S, Nasirov A (2020) Processing, mechanical characterization, and micrography of 3D-printed short carbon fiber reinforced polycarbonate polymer matrix composite material. Int J Adv Manuf Technol 107:3185–3205

Rarani MH, Afarani MR, Zahedi AM (2019) Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos Part B-Eng 175:107–115

Wang P, Zou B, Ding SL, Huang CZ, Shi ZY, Ma YS, Yao P (2020) Preparation of short CF/GF reinforced PEEK composite filaments and their comprehensive properties evaluation for FDM-3D printing. Compos Part B-Eng 198:108175

Dou H, Cheng YY, Ye WG, Zhang DH, Li JJ, Miao ZJ, Rudykh S (2020) Effect of process parameters on tensile mechanical properties of 3D printing continuous carbon fiber-reinforced PLA composites. Materials 13(17):3850

Kamaal M, Anas M, Rastogi H, Bhardwaj N, Rahaman A (2021) Effect of FDM process parameters on mechanical properties of 3D-printed carbon fibre–PLA composite. Progress in Additive Manufacturing 6(1):63–69

Gastelu N, Alexander LU, Solar J, Acha E, Caballero BM, López FA, Marco I (2018) Thermo-catalytic treatment of vapors in the recycling process of carbon fiber-poly (benzoxazine). Pyrolysis 8(11):523

Cheng HB, Sun Y, Wang X, Chang JH, Jing DQ (2019) Recycling carbon fiber/epoxy resin composites by thermal excitation oxide semiconductors. Fiber Polym 20:760–769

Sun C, Wang Y, McMurtrey MD, Jerred ND, Liou F, Li JS (2021) Additive manufacturing for energy: a review. Appl Energy 282(PA):116041

Ding HL, Yuan JF, Zhong GL, Wang NY (2012) Polymer materials and applications. Chemical Industry Press, BeiJing

Funding

This work is financially supported by Jiangsu Key Research & Development plan, National Natural Science Foundation of China (51705237), Qing Lan Project, National Natural Science Foundation of China (52005246), and Open Research Fund by Jiangsu Key Laboratory of Recycling and Reuse Technology for Mechanical and Electronic Products (RRME201806).

Author information

Authors and Affiliations

Contributions

Huanbo Cheng proposed recycling principle of carbon fiber composites by thermal excitation oxide semiconductors. Lijun Guo designed and manufactured special devices of carbon fiber recycling. Zhengchun Qian performed remanufacturing experiments of recycled carbon fiber-reinforced composites based on fused deposition modeling processes. Rui Sun analyzed and interpreted data regarding carbon fiber recycling and composite remanufacturing. Jie Zhang was a major contributor in writing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

This article do not involve animal or human test. The authors confirm that none of the material in the paper, in whole or in part, has been published or is under consideration for publication elsewhere.

Consent to participate and for publication

All the authors listed have approved the manuscript, consented to participate, and consented for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, H., Guo, L., Qian, Z. et al. Remanufacturing of recycled carbon fiber-reinforced composites based on fused deposition modeling processes. Int J Adv Manuf Technol 116, 1609–1619 (2021). https://doi.org/10.1007/s00170-021-07473-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07473-w