Abstract

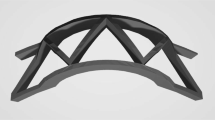

Wire arc additive manufacturing (WAAM) is well suited for the manufacture of sizeable metallic workpieces featuring medium-to-high geometrical complexity due to its high deposition rate, low processing conditions limit, and environmental friendliness. To enhance the current capability of the WAAM process for fabricating structures with complex geometry, this paper proposes a robot-based WAAM strategy adapted specifically for fabricating freeform parts with wire structures composed of multiple struts. Contributions in this work include: (i) The study of bead modelling, which establishes optimal welding parameter selection for the process; (ii) the novel manufacturing strategy, including the adaptive slicing methodology and height control system for accurately depositing every single strut; and (iii) detailed manufacturing procedures for multi-strut branch intersections as well as the collision-free path planning to control the overall fabrication process. To verify the effectiveness of this proposed WAAM approach, two complex wire structures were fabricated successfully, indicating the feasibility of the proposed fabrication strategy.

Similar content being viewed by others

Data Availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

References

Gibson I, Rosen D, Stucker B et al (2015) Directed energy deposition processes. Addit Manuf Technol:245–268. https://doi.org/10.1007/978-1-4939-2113-3_10

Ding D, Pan Z, Cuiuri D, Li H (2015) Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int J Adv Manuf Technol 81:465–481. https://doi.org/10.1007/s00170-015-7077-3

Williams SW, Martina F, Addison AC, Ding J, Pardal G, Colegrove P (2016) Wire + Arc additive manufacturing. Mater Sci Technol (United Kingdom) 32:641–647. https://doi.org/10.1179/1743284715Y.0000000073

Shen C, Pan Z, Ding D, Yuan L, Nie N, Wang Y, Luo D, Cuiuri D, van Duin S, Li H (2018) The influence of post-production heat treatment on the multi-directional properties of nickel-aluminum bronze alloy fabricated using wire-arc additive manufacturing process. Addit Manuf 23:411–421. https://doi.org/10.1016/j.addma.2018.08.008

Yilmaz O, Ugla AA (2016) Shaped metal deposition technique in additive manufacturing: a review. Proc Inst Mech Eng Part B J Eng Manuf 230:1781–1798. https://doi.org/10.1177/0954405416640181

Guo N, Leu MC (2013) Additive manufacturing: technology, applications and research needs. Front Mech Eng 8:215–243. https://doi.org/10.1007/s11465-013-0248-8

Kloft H, Empelmann M, Hack N, Herrmann E, Lowke D (2020) Reinforcement strategies for 3D-concrete-printing. Civ Eng Des 2:131–139. https://doi.org/10.1002/cend.202000022

Gardner L, Kyvelou P, Herbert G, Buchanan C (2020) Testing and initial verification of the world’s first metal 3D printed bridge. J Constr Steel Res 172:172–106233. https://doi.org/10.1016/j.jcsr.2020.106233

Laghi V, Palermo M, Gasparini G, Veljkovic M, Trombetti T (2020) Assessment of design mechanical parameters and partial safety factors for wire-and-arc additive manufactured stainless steel. Eng Struct 225:111314. https://doi.org/10.1016/j.engstruct.2020.111314

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Radel S, Diourte A, Soulié F, Company O, Bordreuil C (2019) Skeleton arc additive manufacturing with closed loop control. Addit Manuf 26:106–116. https://doi.org/10.1016/j.addma.2019.01.003

Huang Y, Zhang J, Hu X et al (2016) FrameFab : robotic fabrication of frame shapes. 35:1–11

Mueller S, Im S, Gurevich S et al (2014) WirePrint: fast 3D printed previews. Proc UIST:273–280

Li Y, Yu S, Chen Y, Yu R, Shi Y (2020) Wire and arc additive manufacturing of aluminum alloy lattice structure. J Manuf Process 50:510–519. https://doi.org/10.1016/j.jmapro.2019.12.049

Laghi V, Palermo M, Gasparini G, Trombetti T (2020) Computational design and manufacturing of a half-scaled 3D-printed stainless steel diagrid column. Addit Manuf 36:101505. https://doi.org/10.1016/j.addma.2020.101505

Wu B, Pan Z, Ding D, Cuiuri D, Li H, Xu J, Norrish J (2018) A review of the wire arc additive manufacturing of metals: properties, defects and quality improvement. J Manuf Process 35:127–139. https://doi.org/10.1016/j.jmapro.2018.08.001

Ding D, Shen C, Pan Z, Cuiuri D, Li H, Larkin N, van Duin S (2016) Towards an automated robotic arc-welding-based additive manufacturing system from CAD to finished part. CAD Comput Aided Des 73:66–75. https://doi.org/10.1016/j.cad.2015.12.003

Yuan L, Ding D, Pan Z, Yu Z, Wu B, van Duin S, Li H, Li W (2020) Application of multi-directional robotic wire arc additive manufacturing process for the fabrication of complex metallic parts. IEEE Trans Ind Informatics 16:1–1. https://doi.org/10.1109/tii.2019.2935233 464

Xu J, Gu X, Ding D, Pan Z, Chen K (2018) A review of slicing methods for directed energy deposition based additive manufacturing. Rapid Prototyp J 24:1012–1025

Wu R, Peng H, Guimbretière F, Marschner S (2016) Printing arbitrary meshes with a 5DOF wireframe printer. ACM Trans Graph 35:1–9. https://doi.org/10.1145/2897824.2925966

Müller J, Grabowski M, Müller C, Hensel J, Unglaub J, Thiele K, Kloft H, Dilger K (2019) Design and parameter identification of wire and arc additively manufactured (WAAM) steel bars for use in construction. Metals (Basel) 9. https://doi.org/10.3390/met9070725

Abe T, Sasahara H (2019) Layer geometry control for the fabrication of lattice structures by wire and arc additive manufacturing. Addit Manuf 28:639–648. https://doi.org/10.1016/j.addma.2019.06.010

Ding D, Pan Z, Cuiuri D, Li H (2015) A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot Comput Integr Manuf 34:8–19. https://doi.org/10.1016/j.rcim.2015.01.003

Luo Y, Li J, Xu J et al (2018) The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding. Mater Des 30:1850–1852. https://doi.org/10.1016/j.matdes.2008.07.015

Yuan L, Pan Z, Ding D, Yu Z, van Duin S, Li H, Li W, Norrish J (2020) Fabrication of metallic parts with overhanging structures using the robotic wire arc additive manufacturing. J Manuf Process 63:0–1. https://doi.org/10.1016/j.jmapro.2020.03.018 24

Funding

This work was supported in part by the National Natural Science Foundation of China under Grant 51805085, in part by the China Scholarship Council under Grant 201908200010.

Author information

Authors and Affiliations

Contributions

All authors provided critical feedback and helped shape the research, analysis and manuscript.

Corresponding author

Ethics declarations

Ethics approval

Authors promise that this manuscript is original, and it has not been published in whole or in part, nor is it being considered for publication or submission elsewhere.

Consent to participate

We make sure the author group, the corresponding author, and the order of authors are all correct at submission.

Consent for publication

The authors have reviewed the present version of the manuscript and approved it for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, Z., Pan, Z., Ding, D. et al. A practical fabrication strategy for wire arc additive manufacturing of metallic parts with wire structures. Int J Adv Manuf Technol 115, 3197–3212 (2021). https://doi.org/10.1007/s00170-021-07375-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07375-x