Abstract

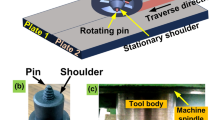

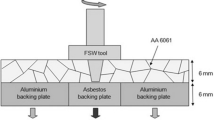

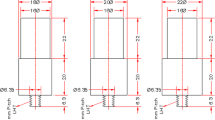

In this study, relationships among process parameters, traverse and rotation speed, and the corrosion resistance at stir region of friction stir welded joints of aluminum alloy AA5052-H32 were evaluated, which were obtained using a tool with featured shoulder and threaded pin. Corrosion analysis was carried out using open circuit potential (OCP) potentiodynamic polarization curves and electrochemical impedance spectroscopy (EIS) tests in a 3.5% (w/v) NaCl solution. Optical microscopy, scanning electron microscopy, and chemical microanalysis were used aiming to study corroded regions. Using a statistical design test completely randomized, complemented by characterization of microstructure evolution and equivalent circuit analysis, there have been correlated welding parameters and corrosion resistance. The resistance of pitting corrosion was associated with grain refinement, heat input, and passivation at stir region for all parameter combinations. Results showed than parameter combination 700 rpm and 100 mm.min−1 exhibited higher corrosion resistance and mechanical properties compared to other used parameters

Similar content being viewed by others

5.References

Anand Sekhar R (2019) Determining the formability of AA5052 sheets in annealed and H32 condition. https://doi.org/10.1088/1742-6596/1355/1/012044

Wang B, Chen XH, Pan FS, Mao JJ, Fang Y (2015) Effects of cold rolling and heat treatment on microstructure and mechanical properties of AA 5052 aluminum alloy. Trans Nonferrous Met Soc China English Ed. https://doi.org/10.1016/S1003-6326(15)63866-3

Shanavas S, Raja Dhas JE (2017) Weldability of AA 5052 H32 aluminium alloy by TIG welding and FSW process - a comparative study. https://doi.org/10.1088/1757-899X/247/1/012016

Kim SJ, Jang SK, Han MS, Kim SK, Kim JS (2011) Effects of precipitation strengthening heat treatment for Al-Mg alloy. Trans Nonferrous Met Soc China English Ed. https://doi.org/10.1016/S1003-6326(11)60845-5

Yogesha KK, Joshi A, Jayaganthan R (2017) Fatigue behavior of ultrafine-grained 5052 Al alloy processed through different rolling methods. J Mater Eng Perform. https://doi.org/10.1007/s11665-017-2705-8

T. E. M. D. S. George, Handbook of aluminum volume 1 physical metallurgy and processes. 1969.

Davis JR (2001) Light metals and alloys-aluminum and aluminum alloys. Alloy Underst Basics

Scotti A, da Silva CLM (2006) The influence of double pulse on porosity formation in aluminum GMAW. J Mater Process Technol

Sarmast A, Serajzadeh S (2019) The influence of welding polarity on mechanical properties, microstructure and residual stresses of gas tungsten arc welded AA5052. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-019-04580-7

Zhang DQ, Park YW, Lee KY (2009) Corrosion behaviors of ND: YAG laser-GMA hybrid weldment of AA5052-H32 Al alloys. Surf Rev Lett. https://doi.org/10.1142/S0218625X09012275

Abbasi M, Givi M, Bagheri B (2020) New method to enhance the mechanical characteristics of Al-5052 alloy weldment produced by tungsten inert gas. Proc Inst Mech Eng Part B J Eng Manuf. https://doi.org/10.1177/0954405420929777

Nur R, Sultan AZ, Suyuti MA (2017) Mechanical properties on friction stir welding of aluminum alloy 5052. ARPN J Eng Appl Sci

Kwon YJ, Shim SB, Park DH (2009) Friction stir welding of 5052 aluminum alloy plates. Trans Nonferrous Met Soc China English Ed. https://doi.org/10.1016/S1003-6326(10)60239-7

Reddy NR, Reddy GM (2016) Friction stir welding of aluminium alloys - a review. Int J Mech Eng Technol

Ma ZY, Feng AH, Chen DL, Shen J (2018) Recent advances in friction stir welding/processing of aluminum alloys: microstructural evolution and mechanical properties. Critical Reviews in Solid State and Materials Sciences. https://doi.org/10.1080/10408436.2017.1358145

Lim Y-B, Lee K-J (2019) Microtexture and microstructural evolution of friction stir welded AA5052-H32 joints. J Weld Join. https://doi.org/10.5781/jwj.2019.37.2.6

Tufaro LN, Manzoni I, Svoboda HG (2015) Effect of heat input on AA5052 friction stir welds characteristics. Procedia Mater Sci. https://doi.org/10.1016/j.mspro.2015.04.152

Cuellar KJQ, Silveira JLL (2017) Analysis of torque in friction stir welding of aluminum alloy 5052 by inverse problem method. J Manuf Sci Eng Trans ASME. https://doi.org/10.1115/1.4035719

Totten G E and MacKenzie D S, Volume 2: alloy production and materials manufacturing. 2003

Gupta AK, Yadav SK (2018) Experimental investigation of friction stir welding on AA 5052 H32. Int J Appl Eng Res 13(12):10365–10371

Shanavas S, Dhas JER (2018) Weld quality prediction of AA 5052-H32 aluminium alloy using neural network approach. https://doi.org/10.1016/j.matpr.2017.11.516

Gudic S, Vrsalovic L, Kliškic M, Jerkovic I, Radonic A, Zekic M (2016) Corrosion inhibition of AA 5052 aluminium alloy in NaCl solution by different types of honey. Int J Electrochem Sci

Wang D, Yang D, Zhang D, Li K, Gao L, Lin T (2015) Electrochemical and DFT studies of quinoline derivatives on corrosion inhibition of AA5052 aluminium alloy in NaCl solution. Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2015.09.206

Shamsudeen S, John ERD (2019) Effect of welding on pitting and intergranular corrosion behavior of marine grade aluminum alloy. Mater Perform Charact. https://doi.org/10.1520/MPC20180118

Bagheri Hariri M, Gholami Shiri S, Yaghoubinezhad Y, Mohammadi Rahvard M (2013) The optimum combination of tool rotation rate and traveling speed for obtaining the preferable corrosion behavior and mechanical properties of friction stir welded AA5052 aluminum alloy. Mater Des. https://doi.org/10.1016/j.matdes.2013.03.027

Reis FM, De Melo HG, Costa I (2006) EIS investigation on Al 5052 alloy surface preparation for self-assembling monolayer. https://doi.org/10.1016/j.electacta.2005.02.118

de Andrade JS, Vieira MRS, Oliveira SH, de Melo Santos SK, Urtiga Filho SL (2020) Study of microbiologically induced corrosion of 5052 aluminum alloy by sulfate-reducing bacteria in seawater. Mater Chem Phys. https://doi.org/10.1016/j.matchemphys.2019.122296

Unfried-Silgado J, Torres-Ardila A, Carrasco-García JC, Rodríguez-Fernández J (2017) Effects of shoulder geometry of tool on microstructure and mechanical properties of friction stir welded joints of AA1100 aluminum alloy. DYNA 84(200). https://doi.org/10.15446/dyna.v84n200.55787

Arbegast WJ (2008) A flow-partitioned deformation zone model for defect formation during friction stir welding. Scr Mater. https://doi.org/10.1016/j.scriptamat.2007.10.031

Chang WS, Cho HJ, Kim HJ, Chun CK (2007) Evaluation of friction spot joining weldability of Al alloys for automotive. Mater Sci Forum 539-543:411–416. https://doi.org/10.4028/www.scientific.net/msf.539-543.411

Dialami N, Cervera M, Chiumenti M, Segatori A (2019) Prediction of joint line remnant defect in friction stir welding. Int J Mech Sci. https://doi.org/10.1016/j.ijmecsci.2018.11.012

W. J. Kyffin, “FSW as a repair technique for surface cracks in stainless steel,” 2007.

A. Rollett, F. Humphreys, G. S. Rohrer, and M. Hatherly, Recrystallization and related annealing phenomena: Second Edition. 2004.

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Materials Science and Engineering R, Reports. https://doi.org/10.1016/j.mser.2005.07.001

Barla M, Jaidi J (2018) Influence of strain hardening behaviour in friction stir welded joints of aluminium-alloy plates. https://doi.org/10.1016/j.matpr.2017.11.639

Du B et al (2020) Effect of extrusion process on the mechanical and in vitro degradation performance of a biomedical Mg-Zn-Y-Nd alloy. Bioact Mater. https://doi.org/10.1016/j.bioactmat.2020.02.002

Krawiec H, Szklarz Z, Vignal V (2012) Influence of applied strain on the microstructural corrosion of AlMg2 as-cast aluminium alloy in sodium chloride solution. Corros Sci. https://doi.org/10.1016/j.corsci.2012.08.047

Acknowledgements

The authors wish to acknowledge the Brazilian Center for Research in Energy and Materials (CNPEM) and professor Ramiro Chamorro, PhD., for providing welded joints. Instituto Tecnológico Metropolitano (ITM) from Medellin and professor Juan F. Santa, PhD., for SEM analysis, and Prof. Mercedes Cely, PhD, for contributions in discussion. The authors are grateful for Universidad Autónoma del Caribe and Universidad de Córdoba for financial support.

Availability of data and materials

All authors affirm that this manuscript is an honest, accurate, and transparent account of the study being reported; that no important aspects of the study have been omitted; and that any discrepancies from the study as planned (and, if relevant, registered) have been explained.

Code availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Funding

This study was funded by Universidad Autónoma del Caribe and Universidad de Córdoba.

Author information

Authors and Affiliations

Contributions

R. Soto Díaz and A. Sandoval fabricated the samples and carried out the experiments. J. Unfried-Silgado conceived the original idea, supervised the project, and wrote the manuscript with support from R. Soto Díaz and A. Sandoval.

Corresponding author

Ethics declarations

Ethics approval

The submitted work is original and it not has been published elsewhere in any form or language.

Consent to participate

This research did not involve using of living beings (humans or animals) or organisms or anything vegetable species nor voluntary or involuntary participation in activities that cause detrimental or defamatory on humans in all experimental activities.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soto-Díaz, R., Sandoval-Amador, A. & Unfried-Silgado, J. Experimental evaluation of rotational and traverse speeds effects on corrosion behavior of friction stir welded joints of aluminum alloy AA5052-H32. Int J Adv Manuf Technol 115, 3213–3223 (2021). https://doi.org/10.1007/s00170-021-07373-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07373-z