Abstract

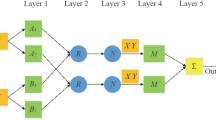

This paper proposes an evolutionary fuzzy neural network (EFNN) for tool wear prediction. Material chips are affected by the cutting conditions during the cutting process. Different tool wear statuses cause material chips to have different colors; thus, the color of a material chip can be a crucial factor in tool wear prediction. In this study, the cutting time and International Commission on Illumination (CIE) xy value were used as the input of the proposed EFNN, and the output was the predicted degree of tool wear. The experimental results indicate that the proposed EFNN with the dynamic group cooperative particle swarm optimization (PSO) algorithm resulted in a smaller mean absolute percentage error (2.83%) than did the backpropagation neural network (9.72%), PSO (7.42%), quantum-based PSO (8.59%), and cooperative PSO (4.09%) algorithms.

Similar content being viewed by others

Data availability

The author confirms that the data supporting the findings of this study are available within the paper. Available: https://tinyurl.com/flank-wear-dataset

References

Debnath S, Reddy MM, Yi QS (2016) Influence of cutting fluid conditions and cutting parameters on surface roughness and tool wear in turning process using Taguchi method. Measurement 78:111–119. https://doi.org/10.1016/j.measurement.2015.09.011

Bar-Hen M, Etsion I (2017) Experimental study of the effect of coating thickness and substrate roughness on tool wear during turning. Tribol Int 110:341–347. https://doi.org/10.1016/j.triboint.2016.11.011

Zhu K, Zhang Y (2019) A generic tool wear model and its application to force modeling and wear monitoring in high speed milling. Mech Syst Signal Process 115:147–161. https://doi.org/10.1016/j.ymssp.2018.05.045

Kong D, Chen Y, Li N (2017) Force-based tool wear estimation for milling process using Gaussian mixture hidden Markov models. Int J Adv Manuf Technol 92:2853–2865. https://doi.org/10.1007/s00170-017-0367-1

Stavropoulos P, Papacharalampopoulos A, Vasiliadis E, Chryssolouris G (2016) Tool wear predictability estimation in milling based on multi-sensorial data. Int J Adv Manuf Technol 82:509–521. https://doi.org/10.1007/s00170-015-7317-6

Madhusudana CK, Kumar H, Narendranath S (2016) Condition monitoring of face milling tool using K-star algorithm and histogram features of vibration signal. Eng Sci Technol 19:1543–1551. https://doi.org/10.1016/j.jestch.2016.05.009

Zhu Z, Sun J, Li J, Huang P (2016) Investigation on the influence of tool wear upon chip morphology in end milling titanium alloy Ti6Al4V. Int J Adv Manuf Technol 83:1477–1485. https://doi.org/10.1007/s00170-015-7690-1

Prakash M, Kanthababu M, Rajurkar KP (2015) Investigations on the effects of tool wear on chip formation mechanism and chip morphology using acoustic emission signal in the microendmilling of aluminum alloy. Int J Adv Manuf Technol 77:1499–1511. https://doi.org/10.1007/s00170-014-6562-4

Corne R, Nath C, El Mansori M, Kurfess T (2017) Study of spindle power data with neural network for predicting real-time tool wear/breakage during inconel drilling. J Manuf Syst 43:287–295. https://doi.org/10.1016/j.jmsy.2017.01.004

Erkan Ö, Işık B, Çiçek A, Kara F (2013) Prediction of damage factor in end milling of glass fibre reinforced plastic composites using artificial neural network. Appl Compos Mater 20:517–536

Ayyıldız EA, Ayyıldız M, Kara F (2021) Optimization of surface roughness in drilling medium-density fiberboard with a parallel robot. Adv Mater Sci Eng 2021:6658968

Kara F, Karabatak M, Ayyıldız M, Nas E (2020) Effect of machinability, microstructure and hardness of deep cryogenic treatment in hard turning of AISI D2 steel with ceramic cutting. J Mater Res Technol 9:969–983

Özgören YÖ, Çetinkaya S, Sarıdemir S, Çiçek A, Kara F (2012) Artificial neural network based modelling of performance of a beta-type Stirling engine. Proc Instit Mechan Eng Part E: J Proc Mechan Eng 227:166–177

Yao Y, Li X, Yuan Z (1999) Tool wear detection with fuzzy classification and wavelet fuzzy neural network. Int J Mach Tools Manuf 39:1525–1538. https://doi.org/10.1016/S0890-6955(99)00018-8

Zadeh LA (1997) Toward a theory of fuzzy information granulation and its centrality in human reasoning and fuzzy logic. Fuzzy Sets Syst 90:111–127

Zadeh LA (2002) Toward a perception-based theory of probabilistic reasoning with imprecise probabilities. J Stat Plan Infer 105:233–264

Thiele H (2002) On algebraic foundations of information granulation. In: Bouchon-Meunier B, Gutiérrez-Ríos J, Magdalena L, Yager RR (eds) Technologies for constructing intelligent systems 1: tasks. Physica-Verlag HD, Heidelberg, pp 113–126

Tanaka K, Wang O (2002) Fuzzy control systems design and analysis: a linear matrix inequality approach, pp 5–48

Chin-Teng L, Chang-Mao Y, Sheng-Fu L, Jen-Feng C, Kumar N (2006) Support-vector-based fuzzy neural network for pattern classification. IEEE Trans Fuzzy Syst 14:31–41

Al-Mahasneh M, Aljarrah M, Rababah T, Alu’datt M (2016) Application of hybrid neural fuzzy system (ANFIS) in food processing and technology. Food Eng Rev 8:351–366

Zhang L, Yang G-H (2020) Adaptive fuzzy fault compensation tracking control for uncertain nonlinear systems with multiple sensor faults. Fuzzy Sets Syst 392:46–59

Chungchoo C, Saini D (2002) On-line tool wear estimation in CNC turning operations using fuzzy neural network model. Int J Mach Tools Manuf 42:29–40. https://doi.org/10.1016/S0890-6955(01)00096-7

Li X, Lim B, Zhou JH, Huang S, Phua SJ, Shaw KC (2009) Fuzzy neural network modelling for tool wear estimation in dry milling operation. Annual Conference of the Prognostics and Health Management Society. PHM 2009

Zhang B, Katinas C, Shin YC (2018) Robust tool wear monitoring using systematic feature selection in turning processes with consideration of uncertainties. J Manuf Sci Eng 140:140. https://doi.org/10.1115/1.4040267

Pratama M., Er M.J., Li X., Gan O.P., Oentaryo R.J., Linn S., 2011, Tool wear prediction using evolutionary Dynamic Fuzzy Neural (EDFNN) Network. IECON 2011—37th Annual Conference of the IEEE Industrial Electronics Society, 4739-44. https://doi.org/10.1109/IECON.2011.6119997.

Ping G., Chunbo X., Yi C., Jing L., Yanqing L., 2014, Adaptive ant colony optimization algorithm. 2014 International Conference on Mechatronics and Control (ICMC), 95-8. https://doi.org/10.1109/ICMC.2014.7231524.

Gong W, Cai Z (2013) Differential evolution with ranking-based mutation operators. IEEE Transact Cyber 43:2066–2081. https://doi.org/10.1109/TCYB.2013.2239988

Mirjalili S, Lewis A (2016) The whale optimization algorithm. Adv Eng Softw 95:51–67. https://doi.org/10.1016/j.advengsoft.2016.01.008

Chen X, Wei X, Yang G, Du W (2020) Fireworks explosion based artificial bee colony for numerical optimization. Knowl-Based Syst 188:105002. https://doi.org/10.1016/j.knosys.2019.105002

Wang D, Tan D, Liu L (2018) Particle swarm optimization algorithm: an overview. Soft Comput 22:387–408. https://doi.org/10.1007/s00500-016-2474-6

Ho SL, Yang S, Ni G, Huang J (2013) A quantum-based particle swarm optimization algorithm applied to inverse problems. IEEE Trans Magn 49:2069–2072. https://doi.org/10.1109/TMAG.2013.2237760

Fvd B, Engelbrecht AP (2004) A cooperative approach to particle swarm optimization. IEEE Trans Evol Comput 8:225–239. https://doi.org/10.1109/TEVC.2004.826069

Leone C, D’Addona D, Teti R (2011) Tool wear modelling through regression analysis and intelligent methods for nickel base alloy machining. CIRP J Manuf Sci Technol 4:327–331

D’Addona D, Segreto T, Simeone A, Teti R (2011) ANN tool wear modelling in the machining of nickel superalloy industrial products. CIRP J Manuf Sci Technol 4:33–37

Diniz AE, Machado ÁR, Corrêa JG (2016) Tool wear mechanisms in the machining of steels and stainless steels. Int J Adv Manuf Technol 87:3157–3168

Rimpault X, Chatelain JF, Klemberg-Sapieha JE, Balazinski M (2017) Tool wear and surface quality assessment of CFRP trimming using fractal analyses of the cutting force signals. CIRP J Manuf Sci Technol 16:72–80

Maier M, Zwicker R, Akbari M, Rupenyan A, Wegener K (2019) Bayesian optimization for autonomous process set-up in turning. CIRP J Manuf Sci Technol 26:81–87

Bonilla Hernández AE, Beno T, Repo J, Wretland A (2016) Integrated optimization model for cutting data selection based on maximal MRR and tool utilization in continuous machining operations. CIRP J Manuf Sci Technol 13:46–50

Ning Y, Rahman M, Wong YS (2001) Investigation of chip formation in high speed end milling. J Mater Process Technol 113:360–367

Su GS, Liu ZQ (2012) Experimental analysis on spherical chips in high-speed machining of hardened AerMet100. Mater Sci Forum 723:67–71

Cui X, Zhao J, Jia C, Zhou Y (2012) Surface roughness and chip formation in high-speed face milling AISI H13 steel. Int J Adv Manuf Technol 61:1–13

Lin C.J, Jhang J. Y., and Chen S. H. The flank wear dataset April. 2021. [Online]. Available: https://tinyurl.com/flank-wear-dataset. Accessed 2021/09/10

Amani M, Falk H, Jensen OD, Vartdal G, Aune A, Lindseth F (2019) Color calibration on human skin images. In: Tzovaras D, Giakoumis D, Vincze M, Argyros A (eds) Computer vision systems. Springer International Publishing, Cham, pp 211–223

Haeghen YV, Naeyaert JMAD, Lemahieu I, Philips W (2000) An imaging system with calibrated color image acquisition for use in dermatology. IEEE Trans Med Imaging 19:722–730

Mokrzycki W, Tatol M (2011) Color difference Delta E—a survey. Mach Graph Visi 20:383–411

Inami T, Tanimoto Y, Minami N, Yamaguchi M, Kasai K (2015) Color stability of laboratory glass-fiber-reinforced plastics for esthetic orthodontic wires. Korean J Orthod 45:130–135. https://doi.org/10.4041/2Fkjod.2015.45.3.130

Pascale D., 2006, RGB coordinates of the Macbeth Color Checker.

Gowda CC, Mayya SG (2014) Comparison of back propagation neural network and genetic algorithm neural network for stream flow prediction. J Comput Environ Sci

Siddique MNH, Tokhi MO (2001) Training neural networks: backpropagation vs. genetic algorithms, IJCNN'01 International Joint Conference on Neural Networks Proceedings (Cat No01CH37222), vol 4, pp 2673–2678

Djaya CRA, Sucianti N, Randy, Wulandhari LA (2017) Hybrid particle swarm optimization and backpropagation neural network for organic and inorganic waste recognition. In: Silhavy R, Senkerik R, Kominkova Oplatkova Z, Prokopova Z, Silhavy P (eds) Artificial intelligence trends in intelligent systems. Springer International Publishing, Cham, pp 168–177

Code availability

Not applicable

Funding

This research was funded by the Ministry of Science and Technology of the Republic of China, grant number MOST 109-2218-E-005-002.

Author information

Authors and Affiliations

Contributions

Conceptualization, C.-J.L.; methodology, C.-J.L. and J.-Y.J.; software, C.-J.L., J.-Y.J., and S.-H.C.; data curation, J.-Y.J., and S.-H.C.; writing-original draft preparation, C.-J.L. and J.-Y.J.; funding acquisition, C.-J.L. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lin, CJ., Jhang, JY. & Chen, SH. Tool wear prediction using a hybrid of tool chip image and evolutionary fuzzy neural network. Int J Adv Manuf Technol 118, 921–936 (2022). https://doi.org/10.1007/s00170-021-07291-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07291-0