Abstract

Laser surface texturing (LST) is widely explored for modifying the surface topography of various materials. In this study, a detailed investigation of laser textured surfaces produced on austenitic stainless steel (AISI 304) was carried out. Three different textures (square, parallel, perpendicular) were produced by a Ti sapphire laser. The processed surfaces were characterized by surface morphology, phase structure, microhardness, surface roughness, and wettability. A ball-on-disk tribometer was used to study the tribological performance of both untextured and textured samples. The experimental observations demonstrate that LST improves both surface wettability and surface roughness. Average surface roughness (Ra) was increased by 350% and the contact angle was reduced from 43° to 22°. The textured surfaces show a lower coefficient of friction and better wear resistance than the untextured surface. Out of the investigated patterns, the square textures exhibited a maximum reduction of 68% in the friction coefficient and a 50% lower wear rate.

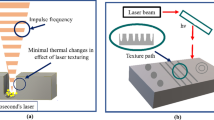

Graphical abstract

Similar content being viewed by others

References

Bruschi S, Pezzato L, Ghiotti A, Dabalà M, Bertolini R (2019) Effectiveness of using low-temperature coolants in machining to enhance durability of AISI 316L stainless steel for reusable biomedical devices. J Manuf Process 39:295–304. https://doi.org/10.1016/j.jmapro.2019.02.003

Hoier P, Malakizadi A, Friebe S, Klement U, Krajnik P (2019) Microstructural variations in 316L austenitic stainless steel and their influence on tool wear in machining. Wear. 428–429:315–327. https://doi.org/10.1016/j.wear.2019.02.024

Andreau O, Koutiri I, Peyre P, Penot JD, Saintier N, Pessard E, De Terris T, Dupuy C, Baudin T (2019) Texture control of 316L parts by modulation of the melt pool morphology in selective laser melting. J Mater Process Technol 264:21–31. https://doi.org/10.1016/j.jmatprotec.2018.08.049

Fu J, Sun J, Cen X, Zhang X, Li F, Wu Y (2018) Growth behavior and orientation relationships in AISI 304 stainless steel during directional solidification. Mater Charact 139:241–248. https://doi.org/10.1016/J.MATCHAR.2018.03.015

Seid Ahmed Y, Paiva J, Covelli D, Veldhuis S (2017) Investigation of coated cutting tool performance during machining of super duplex stainless steels through 3D wear evaluations. Coatings. 7:127. https://doi.org/10.3390/coatings7080127

Kawasegi N, Kawashima T, Morita N, Nishimura K, Yamaguchi M, Takano N (2019) Effect of texture shape on machining performance of textured diamond cutting tool. Precis Eng 60:21–27. https://doi.org/10.1016/j.precisioneng.2019.07.007

Singh DK, Jain VK, Raghuram V, Komanduri R (2005) Analysis of surface texture generated by a flexible magnetic abrasive brush. Wear. 259:1254–1261. https://doi.org/10.1016/j.wear.2005.02.030

Coniglio N, Mezghani S, El Mansori M, Cabrero J (2018) Effect of nano-penning surface texturing on self-cleaning function. Surf Coat Technol 353:126–134. https://doi.org/10.1016/j.surfcoat.2018.07.103

Wang Z, Li YB, Bai F, Wang CW, Zhao QZ (2016) Angle-dependent lubricated tribological properties of stainless steel by femtosecond laser surface texturing. Opt Laser Technol 81:60–66. https://doi.org/10.1016/j.optlastec.2016.01.034

Xing Y, Deng J, Wu Z, Wu F (2017) High friction and low wear properties of laser-textured ceramic surface under dry friction. Opt Laser Technol 93:24–32. https://doi.org/10.1016/J.OPTLASTEC.2017.01.032

Lu L, Zhang Z, Guan Y, Zheng H (2018) Comparison of the effect of typical patterns on friction and wear properties of chromium alloy prepared by laser surface texturing. Opt Laser Technol 106:272–279. https://doi.org/10.1016/j.optlastec.2018.04.020

Kümmel J, Braun D, Gibmeier J, Schneider J, Greiner C, Schulze V, Wanner A (2015) Study on micro texturing of uncoated cemented carbide cutting tools for wear improvement and built-up edge stabilisation. J Mater Process Technol 215:62–70. https://doi.org/10.1016/j.jmatprotec.2014.07.032

Zhang K, Deng J, Xing Y, Li S, Gao H (2015) Effect of microscale texture on cutting performance of WC/Co-based TiAlN coated tools under different lubrication conditions. Appl Surf Sci 326:107–118. https://doi.org/10.1016/j.apsusc.2014.11.059

Niketh S, Samuel GL (2018) Surface texturing for tribology enhancement and its application on drill tool for the sustainable machining of titanium alloy. J Clean Prod 167:253–270. https://doi.org/10.1016/j.jclepro.2017.08.178

Zhang K, Guo X, Sun L, Meng X, Xing Y (2019) Fabrication of coated tool with femtosecond laser pretreatment and its cutting performance in dry machining SLM-produced stainless steel. J Manuf Process 42:28–40. https://doi.org/10.1016/j.jmapro.2019.04.009

Rapoport L, Moshkovich A, Perfilyev V, Lapsker I, Halperin G, Itovich Y, Etsion I (2008) Friction and wear of MoS2 films on laser textured steel surfaces. Surf Coat Technol 202:3332–3340. https://doi.org/10.1016/j.surfcoat.2007.12.009

Rosenkranz A, Costa HL, Profito F, Gachot C, Medina S, Dini D (2019) Influence of surface texturing on hydrodynamic friction in plane converging bearings—an experimental and numerical approach. Tribol Int 134:190–204. https://doi.org/10.1016/j.triboint.2019.01.042

Tang W, Zhou YK, Zhu H (2013) The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl Surf Sci 273(2013):99–204

Wang X, Zhou T, Zhou H, Wu P, Ran M, Gao Z, Zhou H, Kong C, Zhang P (2019) Effects of laser on the non-smooth surface in improving the durability of hot forging tools. Opt Laser Technol 119:105598. https://doi.org/10.1016/j.optlastec.2019.105598

Niketh S, Samuel GL (2018) Drilling performance of micro textured tools under dry, wet and MQL condition. J Manuf Process 32:254–268. https://doi.org/10.1016/j.jmapro.2018.02.012

Vasumathy D, Meena A (2017) Influence of micro scale textured tools on tribological properties at tool-chip interface in turning AISI 316 austenitic stainless steel. Wear. 376–377:1747–1758. https://doi.org/10.1016/j.wear.2017.01.024

Zhou C, Guo X, Zhang K, Cheng L, Wu Y (2019) The coupling effect of micro-groove textures and nanofluids on cutting performance of uncoated cemented carbide tools in milling Ti-6Al-4V. J Mater Process Technol 271:36–45. https://doi.org/10.1016/j.jmatprotec.2019.03.021

Wu Z, Xing Y, Huang P, Liu L (2017) Tribological properties of dimple-textured titanium alloys under dry sliding contact. Surf Coat Technol 309:21–28. https://doi.org/10.1016/j.surfcoat.2016.11.045

Availability of data and materials

Not applicable.

Funding

This research was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) under the CANRIMT Strategic Research Network Grant NETGP 479639-15.

Author information

Authors and Affiliations

Contributions

Yassmin Seid Ahmed performed the cutting experiments as well as metallographic, AFM, SEM, EBSD, XRD analyses, and nanohardness test, planned experimental procedures, and wrote the paper. Jose Mario Paiva reviewed the manuscript. Fred Amorim, Ricardo Torres, and Wagner de Rossi applied LST on the cutting tools. Stephen Clarence Veldhuis was the supervisor of the research team.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Seid Ahmed, Y., M. DePaiva, J., L. Amorim, F. et al. Laser surface texturing and characterization of austenitic stainless steel for the improvement of its surface properties. Int J Adv Manuf Technol 115, 1795–1808 (2021). https://doi.org/10.1007/s00170-021-07284-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07284-z