Abstract

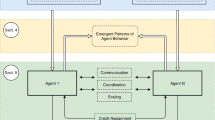

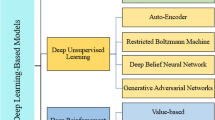

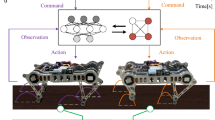

Human-robot collaboration as a multidisciplinary research topic is still pursuing the robots’ enhanced intelligence to be more human-compatible and fit the dynamic and stochastic characteristics of human. However, the uncertainties brought by the human partner challenge the task-planning and decision-making of the robot. When aiming at industrial tasks like collaborative assembly, dynamics on temporal dimension and stochasticities on the order of procedures need to be further considered. In this work, we bring a new perspective and solution based on reinforcement learning, where the problem is regarded as training an agent towards tasks in dynamic and stochastic environments. Concretely, an adapted training approach based on the deep Q learning method is proposed. This method regards both the robot and the human as the agents in the interactive training environment for deep reinforcement learning. With the consideration of task-level industrial human-robot collaboration, the training logic and the agent-environment interaction have been proposed. For the human-robot collaborative assembly tasks in the case study, it is illustrated that our method could drive the robot represented by one agent to collaborate with the human partner even the human performs randomly on the task procedures.

Similar content being viewed by others

Data availability

Data was uploaded as supplementary materials.

References

Gervasi R, Mastrogiaconno L, Franceschini F (2020) A conceptual framework to evaluate human-robot collaboration. Int J Adv Manuf Technol 108(3):841–865. https://doi.org/10.1007/s00170-020-05363-1

Perez L, Rodriguez-Jimenez S, Rodriguez N, Usamentiaga R, Garcia DF, Wang L (2020) Symbiotic human-robot collaborative approach for increased productivity and enhanced safety in the aerospace manufacturing industry. Int J Adv Manuf Technol 106(3-4):851–863. https://doi.org/10.1007/s00170-019-04638-6

Wang L, Gao R, Váncza J, Krüger J, Wang XV, Makris S, Chryssolouris G (2019) Symbiotic human-robot collaborative assembly. CIRP Ann 68(2):701–726. https://doi.org/10.1016/j.cirp.2019.05.002

Tsarouchi P, Matthaiakis A-S, Makris S, Chryssolouris G (2017) On a human-robot collaboration in an assembly cell. Int J Comput Integr Manuf 30(6):580–589. https://doi.org/10.1080/0951192X.2016.1187297

Faccio M, Minto R, Rosati G, Bottin M (2020) The influence of the product characteristics on human-robot collaboration: a model for the performance of collaborative robotic assembly. Int J Adv Manuf Technol 106(5-6):2317–2331. https://doi.org/10.1007/s00170-019-04670-6

Hayes B, Scassellati B (2013) Challenges in shared-environment human-robot collaboration. learning 8 (9)

Krueger V, Rovida F, Grossmann B, Petrick R, Crosby M, Charzoule A, Garcia GM, Behnke S, Toscano C, Veiga G (2019) Testing the vertical and cyber-physical integration of cognitive robots in manufacturing. Robot Comput Integr Manuf 57:213–229. https://doi.org/10.1016/j.rcim.2018.11.011

Liu Q, Liu Z, Xu W, Tang Q, Zhou Z, Pham DT (2019) Human-robot collaboration in disassembly for sustainable manufacturing. Int J Prod Res 57(12):4027–4044. https://doi.org/10.1080/00207543.2019.1578906

Michalos G, Makris S, Spiliotopoulos J, Misios I, Tsarouchi P, Chryssolouris G (2014) ROBO-PARTNER: Seamless human-robot cooperation for intelligent, flexible and safe operations in the assembly factories of the future. Procedia CIRP 23:71–76. https://doi.org/10.1016/j.procir.2014.10.079

Mura MD, Dini G (2019) Designing assembly lines with humans and collaborative robots: A genetic approach. CIRP Ann 68(1):1–4. https://doi.org/10.1016/j.cirp.2019.04.006

Karami A-B, Jeanpierre L, Mouaddib A-I (2010) Human-robot collaboration for a shared mission. In: 5th ACM/IEEE International. Conference on Human-Robot Interaction (HRI):155–156

Zhou L, Tao H, Paszke W, Stojanovic V, Yang H (2020) PD-type iterative learning control for uncertain spatially interconnected systems. Mathematics 8(9):1528. https://doi.org/10.3390/math8091528

Tao H, Li X, Paszke W, Stojanovic V, Yang H (2021) Robust PD-type iterative learning control for discrete systems with multiple time-delays subjected to polytopic uncertainty and restricted frequency-domain. Multidim Syst Sign Process 32(2):671–692. https://doi.org/10.1007/s11045-020-00754-9

Mnih V, Kavukcuoglu K, Silver D, Graves A, Antonoglou I, Wierstra D, Riedmiller M (2013) Playing atari with deep reinforcement learning. arXiv preprint arXiv:13125602

Mnih V, Kavukcuoglu K, Silver D, Rusu AA, Veness J, Bellemare MG, Graves A, Riedmiller M, Fidjeland AK, Ostrovski G (2015) Human-level control through deep reinforcement learning. Nature 518(7540):529–533. https://doi.org/10.1038/nature14236

Silver D, Schrittwieser J, Simonyan K, Antonoglou I, Huang A, Guez A, Hubert T, Baker L, Lai M, Bolton A (2017) Mastering the game of go without human knowledge. Nature 550(7676):354–359. https://doi.org/10.1038/nature24270

Wang L (2019) From intelligence science to intelligent manufacturing. Engineering 5(4):615–618. https://doi.org/10.1016/j.eng.2019.04.011

Liu Z, Wang X, Cai Y, Xu W, Liu Q, Zhou Z, Pham DT (2020) Dynamic risk assessment and active response strategy for industrial human-robot collaboration. Comput Ind Eng 141:106302. https://doi.org/10.1016/j.cie.2020.106302

Sheridan TB (2016) Human–robot interaction: status and challenges. Hum Factors 58(4):525–532. https://doi.org/10.1177/0018720816644364

Chakraborti T, Kambhampati S, Scheutz M, Zhang Y (2017) Ai challenges in human-robot cognitive teaming. arXiv preprint arXiv:170704775

Tsarouchi P, Makris S, Chryssolouris G (2016) Human–robot interaction review and challenges on task planning and programming. Int J Comput Integr Manuf 29(8):916–931. https://doi.org/10.1080/0951192X.2015.1130251

Lasota PA, Shah JA (2015) Analyzing the effects of human-aware motion planning on close-proximity human–robot collaboration. Hum Factors 57(1):21–33. https://doi.org/10.1177/0018720814565188

Pellegrinelli S, Orlandini A, Pedrocchi N, Umbrico A, Tolio T (2017) Motion planning and scheduling for human and industrial-robot collaboration. CIRP Ann 66(1):1–4. https://doi.org/10.1016/j.cirp.2017.04.095

Charalambous G, Fletcher SR, Webb P (2017) The development of a Human Factors Readiness Level tool for implementing industrial human-robot collaboration. Int J Adv Manuf Technol 91(5-8):2465–2475. https://doi.org/10.1007/s00170-016-9876-6

Chen M, Nikolaidis S, Soh H, Hsu D, Srinivasa S (2018) Planning with trust for human-robot collaboration. In: Proceedings of the 2018 ACM/IEEE International Conference on Human-Robot Interaction. pp 307-315

Tan JTC, Duan F, Kato R, Arai T, Hall E (2010) Collaboration planning by task analysis in human-robot collaborative manufacturing system. In: Hall E (ed) Advances in Robot Manipulators. IntechOpen, London

Fiore M, Clodic A, Alami R (2016) On planning and task achievement modalities for human-robot collaboration. Experimental Robotics. Springer, In, pp 293–306

Hawkins KP, Vo N, Bansal S, Bobick AF (2013) Probabilistic human action prediction and wait-sensitive planning for responsive human-robot collaboration. In: 13th IEEE-RAS International Conference on Humanoid Robots (Humanoids). pp 499-506

Hayes B, Scassellati B (2016) Autonomously constructing hierarchical task networks for planning and human-robot collaboration. In: IEEE International Conference on Robotics and Automation (ICRA). pp 5469-5476

Johannsmeier L, Haddadin S (2016) A hierarchical human-robot interaction-planning framework for task allocation in collaborative industrial assembly processes. IEEE Rob Autom Lett 2(1):41–48. https://doi.org/10.1109/LRA.2016.2535907

Kardos C, Kovács A, Váncza J (2016) Towards feature-based human-robot assembly process planning. Procedia CIRP 57:516–521. https://doi.org/10.1016/j.procir.2016.11.089

Ranz F, Hummel V, Sihn W (2017) Capability-based task allocation in human-robot collaboration. Procedia Manuf 9:182–189. https://doi.org/10.1016/j.promfg.2017.04.011

Wang XV, Kemény Z, Váncza J, Wang L (2017) Human–robot collaborative assembly in cyber-physical production: Classification framework and implementation. CIRP Ann 66(1):5–8. https://doi.org/10.1016/j.cirp.2017.04.101

Mateus JC, Claeys D, Limere V, Cottyn J, Aghezzaf E (2019) A structured methodology for the design of a human-robot collaborative assembly workplace. Int J Adv Manuf Technol 102(5-8):2663–2681. https://doi.org/10.1007/s00170-019-03356-3

Kumar A, Dimitrakopoulos R, Maulen M (2020) Adaptive self-learning mechanisms for updating short-term production decisions in an industrial mining complex. J Intell Manuf 31(7):1795–1811. https://doi.org/10.1007/s10845-020-01562-5

Xu W, Tang Q, Liu J, Liu Z, Zhou Z, Duc Truong P (2020) Disassembly sequence planning using discrete bees algorithm for human-robot collaboration in remanufacturing. Robot Comput Integr Manuf 62:101860. https://doi.org/10.1016/j.rcim.2019.101860

Wang P, Liu H, Wang L, Gao RX (2018) Deep learning-based human motion recognition for predictive context-aware human-robot collaboration. CIRP Ann 67(1):17–20. https://doi.org/10.1016/j.cirp.2018.04.066

Kartoun U, Stern H, Edan Y (2010) A human-robot collaborative reinforcement learning algorithm. J Intell Robot Syst 60(2):217–239. https://doi.org/10.1007/s10846-010-9422-y

Akkaladevi SC, Plasch M, Maddukuri S, Eitzinger C, Pichler A, Rinner B (2018) Toward an interactive reinforcement based learning framework for human robot collaborative assembly processes. Front Rob AI 5. https://doi.org/10.3389/frobt.2018.00126

Wang W, Li R, Chen Y, Diekel ZM, Jia Y (2019) Facilitating human-robot collaborative tasks by teaching-learning-collaboration from human demonstrations. IEEE Trans Autom Sci Eng 16(2):640–653. https://doi.org/10.1109/tase.2018.2840345

Modares H, Ranatunga I, Lewis FL, Popa DO (2015) Optimized assistive human–robot interaction using reinforcement learning. IEEE Trans Cybern 46(3):655–667. https://doi.org/10.1109/TCYB.2015.2412554

Gu S, Holly E, Lillicrap T, Levine S (2017) Deep reinforcement learning for robotic manipulation with asynchronous off-policy updates. In: IEEE international conference on robotics and automation (ICRA). pp 3389-3396

Ghadirzadeh A, Butepage J, Maki A, Kragic D, Bjorkman M (2016) A sensorimotor reinforcement learning framework for physical human-robot interaction. 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems.

Chen C, Liu Y, Kreiss S, Alahi A (2019) Crowd-robot interaction: Crowd-aware robot navigation with attention-based deep reinforcement learning. In: 2019 International Conference on Robotics and Automation (ICRA). pp 6015-6022

Trivedi M, Doshi P (2018) Inverse learning of robot behavior for collaborative planning. In: 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). pp 1-9

Foerster JN (2018) Deep multi-agent reinforcement learning. University of Oxford, Dissertation

Sutton RS, Barto AG (2018) Reinforcement learning: An introduction. MIT press, Cambridge

Code availability

Code is available when required.

Funding

This work is supported by National Natural Science Foundation of China (Grant Nos. 51775399 and 51675389), the Fundamental Research Funds for the Central Universities (WUT: 2020III047), and the KTH-CSC programme of China Scholarship Council and KTH Royal Institute of Technology (No. 201906950003).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Liu, Q., Wang, L. et al. Task-level decision-making for dynamic and stochastic human-robot collaboration based on dual agents deep reinforcement learning. Int J Adv Manuf Technol 115, 3533–3552 (2021). https://doi.org/10.1007/s00170-021-07265-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07265-2