Abstract

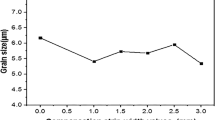

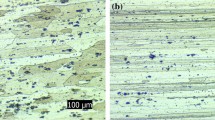

In this study, friction stir welding of AA2014-O and AA2014-T6 aluminum alloy was performed at various welding speeds to evaluate the influence of temper conditions of base metal (BM) on the properties of the welded joints. The results showed strong influence of BM temper conditions on the microstructural morphologies and mechanical behavior of the welded joints. In the 2014-O joints, different zones of weld joint were diffused into each other and there was no clear interface between them. In 2014-T6 joints, there was a distinct demarcation between the nugget zone (NZ), thermomechanically affected zone TMAZ, heat-affected zone (HAZ), and BM. The welded joints in 2014-O temper condition showed increase in hardness in the vicinity of weld center due to grain refinement whereas, in 2014-T6, softening occurred in the same region by the dissolution of strengthening precipitates. The mechanical properties of 2014-O joints were equivalent to the base metal showing a 100% weld efficiency with fracture located in the base metal, whereas 2014-T6 welds exhibited about 70% weld efficiency with fracture located at the NZ/TMAZ interface. All the samples in mechanical testing fractured at retreating side (RS) which exhibited heterogeneity in the mechanical properties of the welded joints. Scanning electron microscopy fractographic analysis revealed a ductile fracture mode comprising of dimples in both temper conditions. The size and shape of the dimples were strongly dependent on base metal temper condition.

Similar content being viewed by others

Data availability

The data presented and/or analyzed during the current study are available from the corresponding author on request.

References

Dursun T, Soutis C (2014) Recent developments in advanced aircraft aluminium alloys. Mater Des 56:862–871. https://doi.org/10.1016/j.matdes.2013.12.002

Davis JR (ed) (2001) Alloying: Understanding the Basics. ASM International® Materials Park, Ohio ISBN: 0-87170-744-6

Givi MKB, Asadi P (2014) Advances in Friction Stir Welding and Processing. Woodhead Publishing, UK ISBN 978-0-85709-454-4

Thomas WM, Nicholas ED, Needham JC, Church MG, Temple-smith P, Smith CJ (1991) International patent application PCT/GB92/02203 and GB patent application no. 9125978.9.

Biro A, Chenelle B, Lados D (2012) Processing, Microstructure, and Residual Stress Effects on Strength and Fatigue Crack Growth Properties in Friction Stir Welding: A Review. Metall Mater Trans B 43:1622–1637. https://doi.org/10.1007/s11663-012-9716-5

Li H, Gao J, Li Q (2018) Fatigue of Friction Stir Welded Aluminum Alloy Joints: A Review. Appl Sci 8:2626. https://doi.org/10.3390/app8122626

Lockwood W, Tomaz B, Reynolds AP (2002) Mechanical response of friction stir welded AA2024: Experiment and modeling. Mater Sci Eng A 323:348–353. https://doi.org/10.1016/S0921-5093(01)01385-5

Orłowska M, Olejnik L, Pietras A, Rosochowski A, Bazarnik P, Golinski J, Brynk T, Lewandowska M (2015) Microstructure and mechanical properties of friction stir welded joints made from ultrafine grained aluminium 1050. Mater Des 88. https://doi.org/10.1016/j.matdes.2015.08.129

Abbasi M, Bagheri B, Keivani R (2015) Thermal analysis of friction stir welding process and investigation into affective parameters using simulation. J Mech Sci Technol 29:861–866. https://doi.org/10.1007/s12206-015-0149-3

Sato Y, Urata M, Kokawa H (2002) Parameters Controlling Microstructure and Hardness during Friction-Stir Welding of Precipitation-Hardenable Aluminum Alloy 6063. Metall Mater Trans A 33:625–635. https://doi.org/10.1007/s11661-002-0124-3

Sato Y, Kokawa H (2001) Distribution of Tensile Property and Microstructure in Frction Stir Weld of 6063 Aluminum. Metall Mater Trans A 32:3023–3031. https://doi.org/10.1007/s11661-001-0177-8

Ma Y, Zhenqiang Z, Liu BQ, Li W (2013) Mechanical properties and fatigue crack growth rates in friction stir welded nugget of 2198-T8 Al–Li alloy joints. Mater Sci Eng A 569:41–47. https://doi.org/10.1016/j.msea.2013.01.044

Meshram S, Reddy G, Rao A (2016) Role of Threaded Tool Pin Profile and Rotational Speed on Generation of Defect Free Friction Stir AA 2014 Aluminium Alloy Welds. Def Sci J 66:57. https://doi.org/10.14429/dsj.66.8566

Aydin H, Tutar M, Durmuş A, Bayram A, Sayaca T (2011) Effect of Welding Parameters on Tensile Properties and Fatigue Behavior of Friction Stir Welded 2014-T6 Aluminum Alloy. Trans Indian Inst Metals 65:10.1007/s12666-011-0069-6

Ramanjaneyulu K, Reddy GM, Rao AV, Markandeya R (2013) Structure-Property Correlation of AA2014 Friction Stir Welds: Role of Tool Pin Profile. J Mater Eng Perform 22:2224–2240

Norman, A., Brough, Ian, Prangnell, Phil. (2000). High Resolution EBSD Analysis of the Grain Structure in an AA2024 Friction Stir Weld. Mater Sci Forum. 331-337. 1713-1718. 10.4028/www.scientific.net/MSF.331-337.1713.

Jones MJ, Heurtier P, Desrayaud C, Montheillet F, Alléhaux D, Driver J (2005) Correlation between microstructure and microhardness in a friction stir welded 2024 aluminium alloy. Scr Mater 52:693–697. https://doi.org/10.1016/j.scriptamat.2004.12.027

Zhang Z, Li W, Li J, Chao YJ, Vairis A (2015) Microstructure and anisotropic mechanical behavior of friction stir welded AA2024 alloy sheets. Mater Charact 107:112–118. https://doi.org/10.1016/j.matchar.2015.06.039

Huaxia Zhao, Chunlin Dong, Guohong Luan (2011) Material flow behaviour of 2024-T351 aluminium alloys friction stir welding. 1-4. https://doi.org/10.1049/cp.2011.1048.

Li G-h, Zhou L, Luo L-y, Wu X-m, Guo N (2021) Material flow behavior and microstructure evolution during refill friction stir spot welding of alclad 2A12-T4 aluminum alloy. Int J Miner Metall Mater. https://doi.org/10.1007/s12613-020-1998-z

Qin D, Fu L, Shen Z (2019) Visualisation and numerical simulation of material flow behaviour during high-speed FSW process of 2024 aluminium alloy thin plate. Int J Adv Manuf Technol 102:1901–1912. https://doi.org/10.1007/s00170-018-03241-5

Li T, Shi Q-y, Li H-K (2007) Residual stresses simulation for friction stir welded joint. Sci Technol Weld Join 12:664–670. https://doi.org/10.1179/174329307X236832

Fratini L, Pasta S, Reynolds AP (2009) Fatigue crack growth in 2024-T351 friction stir welded joints: Longitudinal residual stress and microstructural effects. Int J Fatigue 31:495–500. https://doi.org/10.1016/j.ijfatigue.2008.05.004

Delijaicov S, Silva PA, Resende HB, Batalha MH (2018) Effect of Weld Parameters on Residual Stress, Hardness and Microstructure of Dissimilar AA2024-T3 and AA7475-T761 Friction Stir Welded Joints. Materi Res-ibero-american J Mater 21

Nadikudi BK, Kumar A, Davidson M (2011) A review of friction stir welding of AA6061 aluminium alloy. ARPN J Eng Appl Sci 6:61–63 N. Bhanodaya Kiran Babu, A. Prabhu Kumar and M. Joseph Davidson

ASTM E407-07 Standard Practice for Microetching Metals and Alloys. ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States

ASTM E08-04 Standard Test Methods for Tension Testing of Metallic Materials. ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States

Chen Y, Liu H, Feng J (2006) Friction stir welding characteristics of different heat-treated-state 2219 aluminum alloy plates. Mater Sci Eng A 420:21–25. https://doi.org/10.1016/j.msea.2006.01.029

Sutton M, Yang B, Reynolds AP, Taylor R (2002) Microstructural studies of friction stir welds in 2024-T3 aluminum. Mater Sci Eng A 323:160–166. https://doi.org/10.1016/S0921-5093(01)01358-2

Ali Saleh A (2018) Effect of heat treatment on the mechanical properties of AA2014 alloy. Contemp Eng Sci 11:3409–3419. https://doi.org/10.12988/ces.2018.87345

Devuri V, Cheepu MM, Kumar B, Mahapatra M (2018) Analysing the Friction Stir Welded Joints of AA2219 Al-Cu Alloy in Different Heat-Treated-State. IOP Conf Ser Mater Sci Eng 330:012074. https://doi.org/10.1088/1757-899x/330/1/012074

Rajendran C, Srinivasan K, Balasubramanian V, Balaji H, Selvaraj P (2016) Influences of post weld heat treatment on tensile strength and microstructure characteristics of friction stir welded butt joints of AA2014-T6 aluminum alloy. J Mech Behav Mater 25. https://doi.org/10.1515/jmbm-2016-0011

Devuri V, Cheepu M, Mohan R, Palukuri S, Kumaran S, Srinivasan N (2019) Characterization of Microstructure and Mechanical Properties of AA2219-O and T6 Friction Stir Welds. Mater Sci Forum 969:205–210. https://doi.org/10.4028/www.scientific.net/MSF.969.205

Aydin H, Bayram A, Uguz A, Akay S (2009) Tensile properties of friction stir welded joints of 2024 aluminum alloys in different heat-treated-state. Mater Des 30:2211–2221. https://doi.org/10.1016/j.matdes.2008.08.034

Al-Dwairi A, Abdelall E’a, Rivero I (2020) Effect of Pre-welding Heat Treatment on the Mechanical Properties of Friction Stir Welded Al–4 wt.%Cu Alloys. Metallogr Microstruct Anal. https://doi.org/10.1007/s13632-020-00628-3

Xu W, Liu J, Zhu H, Fu L (2013) Influence of welding parameters and tool pin profile on microstructure and mechanical properties along the thickness in a friction stir welded aluminum alloy. Mater Des 47:599–606. https://doi.org/10.1016/j.matdes.2012.12.065

Ji S, Meng X, Liu J, Zhang LG, Gao SS (2014) Formation and mechanical properties of stationary shoulder friction stir welded 6005A-T6 aluminum alloy. Mater Des 62:113–117. https://doi.org/10.1016/j.matdes.2014.05.016

Olson DL et al (eds) ASM handbook, Vol. 6, ‘Welding, brazing and soldering’. ASM International, Materials Park, OH

Frigaard Ø, Grong Ø, Midling O (2001) A Process Model for Friction Stir Welding of Age Hardening Aluminum Alloys. Metall Mater Trans A 32:1189–1200. https://doi.org/10.1007/s11661-001-0128-4

Lee W, Yeon Y-M, Jung S-B (2004) Mechanical Properties Related to Microstructural Variation of 6061 Al Alloy Joints by Friction Stir Welding. Mater Trans 45:1700–1705. https://doi.org/10.2320/matertrans.45.1700

Liu H, Zhang H, Pan Q, Yu L (2011) Effect of friction stir welding parameters on microstructural characteristics and mechanical properties of 2219-T6 aluminum alloy joints. Int J Mater Form 5. https://doi.org/10.1007/s12289-011-1048-5

İpekoğlu G, Erim S, Goren-Kıral B, Çam G (2013) Investigation into the effect of temper condition on friction stir weldability of AA6061 Al-alloy plates. Kovove Mater 51:155–163. https://doi.org/10.4149/km-2013-3-155

İpekoğlu G, Erim S, Çam G (2014) Effects of temper condition and post weld heat treatment on the microstructure and mechanical properties of friction stir butt-welded AA7075 Al alloy plates. Int J Adv Manuf Technol 70. https://doi.org/10.1007/s00170-013-5255-8

Liu H, Fujii H, Maeda M, Nogi K (2003) Heterogeneity of mechanical properties of friction stir welded joints of 1050-H24 aluminum alloy. J Mater Sci Lett 22:441–444. https://doi.org/10.1023/A:1022959627794

Rezaei MR, Toroghinejad MR, Ashrafizadeh F (2011) Effects of ARB and ageing processes on mechanical properties and microstructure of 6061 aluminum alloy. J Mater Process Technol 211:1184–1190. https://doi.org/10.1016/j.jmatprotec.2011.01.023

Acknowledgements

The authors acknowledge the technical support provided by Mr. Talha Ahmed, Mr. Muhammad Shahbaz, and Mr. Aamir Siddique in FSW. They are also grateful to Mr. Munir Ahmed for assistance in optical and hardness sample preparation, Mr. Muhammad Israr for tensile testing, and Mr. Muhammad Tahir Khan for SEM analysis.

Code availability

Not applicable

Funding

This research work is partially funded by the Institute of Space technology Islamabad, Pakistan.

Author information

Authors and Affiliations

Contributions

The authors’ contributions are as follows: Wali Muhammad conceptualized, planned, and carried out the experiments. Muhammad Atiq ur Rahman contributed to the analysis and interpretation of results. Abdul Wadood and Hamid Zaigham validated, prepared, and edited the original draft. Wilayat Husain and Anjum Tauqir supervised and critically reviewed the research and manuscript. All the authors provided valuable feedback and helped to shape the project, analysis, and the manuscript.

Corresponding authors

Ethics declarations

Ethics approval

All authors confirm that they follow all ethical guidelines. All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Consent to participate

The authors agree with the participation.

Consent for publication

The authors agree with the publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muhammad, W., Husain, W., Tauqir, A. et al. Assessment of microstructure and mechanical properties of friction stir welded AA2014-O and AA2014-T6 sheets. Int J Adv Manuf Technol 115, 2255–2267 (2021). https://doi.org/10.1007/s00170-021-07249-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07249-2