Abstract

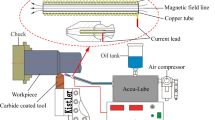

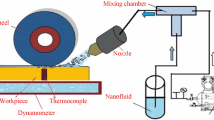

As a typical representative of green lubrication/cooling mode, minimum quantity lubrication (MQL) is widely recognized by the industry for its excellent machining performance. However, the oil mist generated from oil-based MQL machining process has a direct impact on the ambient air quantity and then does harm those who permanently work in this environment. To alleviate this defect, a novel lubrication strategy named magnetic minimum quantity lubrication (mMQL) allocated with water-based Fe3O4 nanofluid as cutting fluid was proposed. The effect of different magnetic induction on the kinetic viscosity and atomization performance of water-based Fe3O4 nanofluid was investigated. The deposition property of water-based Fe3O4 nanofluid droplets produced by mMQL and LB-2000 vegetable oil droplets produced by MQL were compared, and the corresponding oil mist concentrations (PM10, PM2.5) were also measured. Eventually, the machining performances of water-based Fe3O4 nanofluid mMQL and LB-2000 vegetable oil MQL applied in milling of 430 stainless steel were compared. Results exhibited that water-based Fe3O4 nanofluid presented higher kinetic viscosity and larger droplet size under higher magnetic induction intensity. Water-based Fe3O4 nanofluid mMQL with magnetic induction intensity of 60–100 mT displayed lower PM10 and PM2.5 concentrations, tool flank wear value, milling force, and surface roughness value in comparison with LB-2000 vegetable oil applied in MQL. This water-based Fe3O4 nanofluid used in mMQL showed higher kinetic viscosity and atomized larger droplet-size and thus presented further deposition quantity, which demonstrated alternative cutting performance and lessened the oil mist particles floating in the operating environment.

Similar content being viewed by others

References

Yıldırım ÇV, Sarıkaya M, Kıvak T, Sirin S (2019) The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol Int 134:443–456. https://doi.org/10.1016/j.triboint.2019.02.027

Ni CB, Zhu LD (2020) Investigation on machining characteristics of TC4 alloy by simultaneous application of ultrasonic vibration assisted milling (UVAM) and economical-environmental MQL technology. J Mater Process Tech 278:116518. https://doi.org/10.1016/j.jmatprotec.2019.116518

Pratap A, Patra K (2020) Combined effects of tool surface texturing, cutting parameters and minimum quantity lubrication (MQL) pressure on micro-grinding of BK7 glass. J Manuf Process 54:374–392. https://doi.org/10.1016/j.jmapro.2020.03.024

Sharma AK, Tiwari AK, Dixit AR (2016) Effects of minimum quantity lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: a comprehensive review. J Clean Prod 127:1–18. https://doi.org/10.1016/j.jclepro.2016.03.146

Khanafer K, Eltaggaz A, Deiab I, Agarwal H, Abdul-latif A (2020) Toward sustainable micro-drilling of Inconel 718 superalloy using MQL-Nanofluid. Int J Adv Manuf Tech 107(7-8):3459–3469. https://doi.org/10.1007/s00170-020-05112-4

Gao T, Li CH, Yb Z, Yang M, Jia DZ, Jin T, Huo YL, Li RZ (2019) Dispersing mechanism and tribological performance of vegetable oil-based CNT nanofluids with different surfactants. Tribol Int 2019(131):51–63. https://doi.org/10.1016/j.triboint.2018.10.025

Gao T, Li CH, Jia DZ, Zhang YB, Yang M, Wang XM, Cao HJ, Li RZ, Ali HM, Xu XF (2020) Surface morphology assessment of CFRP transverse grinding using CNT nanofluid minimum quantity lubrication. J Clean Prod 277:123328. https://doi.org/10.1016/j.jclepro.2020.123328

Shokrani A, Al-Samarrai I, Newman ST (2019) Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy. J Manuf Process 43(A):229–243. https://doi.org/10.1016/j.jmapro.2019.05.006

Yang M, Li CH, Zhang YB, Jia DZ, Li RZ, Hou YL, Cao HJ, Wang J (2019) Predictive model for minimum chip thickness and size effect in single diamond grain grinding of zirconia ceramics under different lubricating conditions. Ceram Int 45(12):14908–14920. https://doi.org/10.1016/j.ceramint.2019.04.226

Yang M, Li CH, Zhang YB, Jia DZ, Zhang XP, Hou YL, Li RZ, Wang J (2017) Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions. Int J Mach Tool Manu 122:41–51. https://doi.org/10.1016/j.ijmachtools.2017.06.003

Yang M, Li CH, Zhang YB, Jia DZ, Li RZ, Hou YL, Cao HJ (2019) Effect of friction coefficient on chip thickness models in ductile-regime grinding of zirconia ceramics. Int J Adv Manuf Tech 102(5-8):2617–2632. https://doi.org/10.1007/s00170-019-03367-0

Guo SM, Li CH, Zhang YB, Wang YG, Li BK, Yang M, Zhang XP, Liu GP (2017) Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based alloy. J Clean Prod 140:1060–1076. https://doi.org/10.1016/j.jclepro.2016.10.073

Zhao W, Ni HE, Li L, Yang YF, Shi Q (2014) Investigation on the influence of system parameters on ambient air quality in minimum quantity lubrication milling process. J Mech Eng-En 50(13):184–189. https://doi.org/10.3901/JME.2014.13.184

Massin N, Bohadana AB, Wild P, Goutet P, Kirstetter H, Toamain JP (1996) Airway responsiveness, respiratory symptoms, and exposures to soluble oil mist in mechanical workers. Occupational & Environmental Medicine 53(11):748–752. https://doi.org/10.1136/oem.53.11.748

Lawal SA, Choudhury IA, Nukman Y (2013) A critical assessment of lubrication techniques in machining processes: a case for minimum quantity lubrication using vegetable oil-based lubricant. J Clean Prod 41:210–221. https://doi.org/10.1016/j.jclepro.2012.10.016

Tian J (2009) An investigation of ambient air quality in cutting process with cryogenic minimum quantity lubrication. Nanjing University of Aeronautics and Astronautics, Nanjing.

Aoyama T, Kakinuma Y, Yamashita M, Aoki M (2008) Development of a new lean lubrication system for near dry machining process. CIRP Ann Manuf Technol 57(1):125–128. https://doi.org/10.1016/j.cirp.2008.03.094

Wlaschitz P, Hoflinger W (2007) A new measuring method to detect the emissions of metal working fluid mist. J Hazard Mater 144(3):736–741. https://doi.org/10.1016/j.jhazmat.2007.01.104

Chen MR, Tsai PJ, Chang CC, Shih TS, Lee WJ, Liao PC (2007) Particle size distributions of oil mists in workplace atmospheres and their exposure concentrations to workers in a fastener manufacturing industry. J Hazard Mater 146(1-2):393–398. https://doi.org/10.1016/j.jhazmat.2006.12.036

MWFSAC (OSHA) (2008) Metalworking fluids safety and health best practice manual. Washington DC: Occupational safety & Health administration.

Smolinski JM, Gulari E, Manke CW (1996) Atomization of dilute polymer additives as mist suppressants in metal cutting fluids. AIChE Journal. 42(5):1201–1202

Marano RS, Smolinski JM, Manke CW, Gulari E, Messick RL (1997) Polymer additives as mist suppressants in metal cutting fluids. Lub Eng 53(10):25–36

Ii M, Eda H, Imai T, Nishimura M, Kawasaki T, Shimizu J, Yamamoto T, Zhou L (2000) Development of high water-content cutting fluids with a new concept: fire prevention and environmental protection. Precis Eng 24(3):231–236. https://doi.org/10.1016/S0141-6359(00)00036-2

Xu MC, Dai QW, Huang W, Wang XL (2020) Using magnetic fluids to improve the behavior of ball bearings under starved lubrication. Tribo Int 141:105950. https://doi.org/10.1016/j.triboint.2019.105950

Wang LJ, Guo CW, Ryuichiro Y, Yue W (2009) Tribological properties of Mn–Zn–Fe magnetic fluids under magnetic field. Tribo Int 42(6):792–797. https://doi.org/10.1016/j.triboint.2008.10.009

Wang LJ, Guo CW, Ryuichiro Y (2008) Experimental research on tribological properties of Mn0.78Zn0.22Fe2O4 magnetic fluids. J Tribol 130(3):031801. https://doi.org/10.1115/1.2913539

Huang W, Shen C, Liao SJ, Wang XL (2011) Study on the ferrofluid lubrication with an external magnetic field. Tribol Lett 41:145–151. https://doi.org/10.1007/s11249-010-9693-2

Park KH, Olortegui YJ, Yoon MC, Kwon P (2010) A study on droplets and their distribution for minimum quantity lubrication (MQL). Int J Mach Tools Manuf 50:824–833. https://doi.org/10.1016/j.ijmachtools.2010.05.001

Yang C, Bian X, Qin J (2014) An investigation of a viscosity-magnetic field hysteretic effect in nano-ferrofluid. J Mol Liq 196:357–362. https://doi.org/10.1016/j.molliq.2014.04.021

Zubarev AY, Iskakova LY (2004) To the thery of rheological properties of ferrofluids: influence of drop-like aggregates. Physica A: Statistical Mechanics and its Applications 343(15):65–80. https://doi.org/10.1016/j.physa.2004.06.069

Availability of data and material

All the experimental data and material are reflected in this article.

Code availability

Not applicable.

Funding

This study was financially supported by the Ningbo Natural Science Foundation with the project number of 202003N4190, General scientific research projects of Zhejiang Provincial Department of Education with the project number of Y202043602, and National Natural Science Foundation of China with the project number of 51775507.

Author information

Authors and Affiliations

Contributions

Conceptualization: Tao Lv, Xuefeng XuMethodology: Tao Lv, Xuefeng Xu, WZOriginal draft writing: Tao Lv, Chengcheng NiuInvestigation: Tao LvReview: Xuefeng Xu, Aibing Yu, Xiaodong HuLanguage editing: Tao Lv, Aibing YuSupervision: Tao Lv, Xuefeng XuFinancial support: Tao Lv, Xuefeng Xu

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors agree to publish.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lv, T., Xu, X., Yu, A. et al. Ambient air quantity and cutting performances of water-based Fe3O4 nanofluid in magnetic minimum quantity lubrication. Int J Adv Manuf Technol 115, 1711–1722 (2021). https://doi.org/10.1007/s00170-021-07231-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07231-y