Abstract

The structure and mechanical properties of an alloy of the aluminum-magnesium system with a scandium content of no more than 0.1% (wt.) (experimental alloy) at the stages of obtaining sheet semi-finished products have been investigated. The macro and micro structure of cast, hot, and cold rolled sheet semi-finished products has been studied by the methods of light and diffraction transmission electron microscopy, and their mechanical properties have been tested. Casting of ingots, hot, and cold rolling of the alloy was carried out in the conditions of a metallurgical enterprise. The section of the ingots was a rectangle 300 × 1460 mm in size. Preparation of ingots for rolling included milling of all surfaces and two-stage annealing at temperatures of 350 °C (first stage) and 425 °C (second stage). Rolling was carried out across the casting direction. For hot rolling, the billets were heated to 400–410 °C and carried out on a reversible hot rolling mill of grade quart with a roll barrel length of 2800 mm to a thickness of 8.2–9.2 mm. Then, the strips were rolled into rolls and annealed according to the following regime: temperature 390–400 °С, holding for 1 h, cooling with a furnace to 250–270 °С, and unloading into air. Cold rolling was carried out on a QUARTO mill of the CRM grade with a roll barrel length of 2800 mm to a thickness of 5.9–6.3 mm. Microstructural analysis was performed on a Carl Zeiss Axio Observer A1m light microscope using the AxioVision software package. The fine structure of semi-finished products was studied using Tecnai 30 G2 and JEM-2100 EX transmission electron microscopes. The chemical composition of dispersed particles of the secondary phases was determined using energy dispersive X-ray microanalysis (EDX) of thin foils in transmission using an INCA x-sight attachment. It is shown that alloying the experimental alloy with small additions of scandium, zirconium, and manganese leads to the formation of a supersaturated solid solution in the ingot. And upon annealing of the ingot and subsequent hot and cold rolling, a subgrain structure with inclusions of Al6Mn and Al3(Sc, Zr) phases of distribution density is formed in the alloy structure, explaining dispersion and structural hardening of sheet semi-finished products. It was found that the mechanical properties of cold-rolled sheets from the experimental alloy significantly exceed the properties of alloy 5083 with the same magnesium content. But without scandium and are approximately on the same level with alloy 1570 in which the scandium content in comparison with the experimental alloy is three times higher.

Similar content being viewed by others

Availability of data and materials

Not applicable.

References

Juri A (2015) Gorbunov, The role and prospects of rare Earth metals in the development of physical-mechanical characteristics and applications of deformable aluminum alloys. Journal of Siberian Federal University. Eng Technol 8(5):636–645

Yu A, Filatov AD (2011) Plotnikov, Structure and properties of deformed semi-finished products from aluminum alloy 01570C of the Al – Mg – Sc system for the RSC “Energia” product. Tekhnol legkikh splavov [Light alloy technol] 2:15–26

Bronz AV, Efremov VI, Plotnikov AD, Chernyavskiy AG (2014) Alloy Alloy 1570C — material for pressurized structures of advanced reusable vehicles of RSC “Energia”. Kosmicheskaya tekhnika i tekhnol [Space Eng Technol] 4(7):62–67

Yashin VV, Aryshenskiy VY, Latushkin IA, Tepterev MS (2018) Substantiation of a manufacturing technology of flat rolled products from Al – Mg – Sc based alloys for the aerospace industry. Tsvetnye Metally 7:75–82. https://doi.org/10.17580/tsm.2018.07.12

Pouraliakbar H, Jandaghi MR (2018) Mechanistic insight into the role of severe plastic deformation and post-deformation annealing in fracture behavior of Al-Mn-Si alloy. Mech Mater 122:145–158. https://doi.org/10.1016/j.materresbull.2018.09.011

Pouraliakbar H, Jandaghi MR, Mohammadi Baygi SJ, Khalaj G (2017) Microanalysis of crystallographic characteristics and structural transformations in SPDed Al single bond Mn single bond Si alloy by dual-straining. J Alloys Compd 696:1189–1198. https://doi.org/10.1016/j.jallcom.2016.12.086

Buranova Y, Kulitskiy V, Peterlechner M, Mogucheva A, Kaibyshev R, Divinski SV, Wilde G (2017) Al3(Sc,Zr)-based precipitates in Al–Mg alloy: effect of severe deformation. Acta Mater 124:210–224. https://doi.org/10.1016/j.actamat.2016.10.064

Jiang J, Jiang F, Zhang M, Tang Z, Tong M (2020) Recrystallization behavior of Al-Mg-Mn-Sc-Zr alloy based on two different deformation ways. Mater Lett 265:127455. https://doi.org/10.1016/j.matlet.2020.127455

Zakharov VV, Rostova TD (2014) Hardening of aluminum alloys due to scandium alloying. Metal Sci Heat Treat 55(11-12):660–664. https://doi.org/10.1007/s11041-014-9686-0

Zakharov VV, Fisenko IA (2019) Some principles of alloying of aluminum alloys with scandium and zirconium in ingot production of deformed semiproducts. Metal Sci Heat Treat 61(3-4):217–221. https://doi.org/10.1007/2Fs11041-019-00403-4

Zakharov VV, Filatov YA, Fisenko IA (2020) Scandium alloying of aluminum alloys. Metal Sci Heat Treat 62:518–523. https://doi.org/10.1007/s11041-020-00595-0

Zakharov VV (2014) Combined alloying of aluminum alloys with scandium and zirconium. Metal Sci Heat Treat 56(5-6):281–286. https://doi.org/10.1007/s11041-014-9746-5

Sun Y, Pan Q, Luo Y, Liu S, Wang W, Ye J, Shi Y, Huang Z, Xiang S, Liu Y (2021) The effects of scandium heterogeneous distribution on the precipitation behavior of Al3(Sc, Zr) in aluminum alloys. Mater Charact 174:110971. https://doi.org/10.1016/j.matchar.2021.110971

Baranov V, Sidelnikov S, Voroshilov D, Yakivyuk O, Konstantinov I, Sokolov R, Belokonova I, Zenkin E, Frolov V (2018) Study of strength properties of semi-finished products from economically alloyed high-strength aluminium-scandium alloys for application in automobile transport and shipbuilding. Open Eng 8(1):69–76. https://doi.org/10.1515/eng-2018-0005

Zakharov VV (2015) Kinetics of decomposition of the solid solution of scandium in aluminum in binary Al – Sc alloys. Metal Sci Heat Treat 57(7-8):410–414. https://doi.org/10.1007/s11041-015-9897-z

Li G, Zhao N, Liu T, Li J, He C, Shi C, Liu E, Sha J (2014) Effect of Sc/Zr ratio on the microstructure and mechanical properties of new type of Al–Zn–Mg–Sc–Zr alloys. Mater Sci Eng A 617:219–227. https://doi.org/10.1016/j.msea.2014.08.041

Mondol S, Alamb T, Banerjee R, Kumar S, Chattopadhyay K (2017) Development of a high temperature high strength Al alloy by addition of small amounts of Sc and Mg to 2219 alloy. Mater Sci Eng А687:221–231. https://doi.org/10.1016/j.msea.2017.01.037

Shi C, Liang Z, Wu G, Zhang X, Chen A, Tao J (2017) Effects of Sc addition on the microstructure and mechanical properties of cast Al-3Li-1.5Cu-0.15Zr alloy. Mater Sci Eng А680:232–238. https://doi.org/10.1016/j.msea.2016.10.063

Pereiraa PHR, Wang YC, Huang Y, Langdon TG (2017) Influence of grain size on the flow properties of an Al-Mg-Sc alloy over seven orders of magnitude of strain rate. Mater Sci Eng А685:367–376. https://doi.org/10.1016/j.msea.2017.01.020

Rajinikanth V, Vikas J, Akkimardi VG, Mainak G, Venkateswarlu K (2007) Transmission electron microscopy studies on the effect of strain on Al and Al–1% Sc alloy. Scr Mater 57:425–428. https://doi.org/10.1016/j.scriptamat.2007.04.038

Yan K, Chen ZW, Zhao YN, Ren CC, Lu WJ, Aldeen AW (2021) Morphological characteristics of Al3Sc particles and crystallographic orientation relationships of Al3Sc/Al interface in cast Al-Sc alloy. J Alloys Compd 861:158491. https://doi.org/10.1016/j.jallcom.2020.158491

Zhao Y, Zhang W, Koe B, Du W, Wang M, Wang W, Boller E, Rack A, Sun Z, Shu D, Sun B, Mi J (2020) Multiscale characterization of the nucleation and 3D structure of Al3Sc phases using electron microscopy and synchrotron X-ray tomography. Mater Charact 164:110353. https://doi.org/10.1016/j.matchar.2020.110353

Luo Y, Pan Q, Sun Y, Liu S, Sun Y, Liang L, Li X, Wang X, Li M (2020) Hardening behavior of Al-0.25Sc and Al-0.25Sc-0.12Zr alloys during isothermal annealing. J Alloys Compd 818:152922. https://doi.org/10.1016/j.jallcom.2019.152922

Zhang W, Wu Y, Lu H, Lao G, Wang K, Ye Y, Li P (2020) Discontinuous precipitation of nano-Al3Sc particles in Al-Sc alloy and its effect on mechanical property. Int J Nanosci 19(1):1850047. https://doi.org/10.1142/S0219581X18500473

Dong Q, Howells A, Lloyd DJ, Gallerneault M, Fallah V (2020) Effect of solidification cooling rate on kinetics of continuous/discontinuous Al3(Sc,Zr) precipitation and the subsequent age-hardening response in cold-rolled AlMgSc(Zr) sheets. Mater Sci Eng A 772:138693. https://doi.org/10.1016/j.msea.2019.138693

Zakharov VV (2018) Prospects of creation of aluminum alloys sparingly alloyed with scandium. Metal Sci Heat Treat 60(3-4):172–176. https://doi.org/10.1007/s11041-018-0256-8

Akopyan TK, Letyagin NV, Belov NA, Shurkin PK (2019) New eutectic type Al alloys based on the Al-Ca-La(-Zr, Sc) system. Mater Today: Proceed 19:2009–2012. https://doi.org/10.1016/j.matpr.2019.07.062

Belov NA, Naumova EA, Doroshenko VV, Korotkova NO (2018) Phase composition, structure, and hardening of alloys containing 6% (Ca + Si) in the system Al–Ca–Si–Zr–Sc. Phys Met Metallogr 119(12):1184–1190. https://doi.org/10.1134/S0031918X18120037

Belov NA, Naumova EA, Bazlova TA, Doroshenko VV (2017) Phase Composition and hardening of castable Al – Ca – Ni – Sc alloys containing 0.3% Sc. Metal Sci Heat Treat 59(1-2):76–81. https://doi.org/10.1007/s11041-017-0106-0

Belov NA, Naumova EA, Bazlova TA, Alekseeva EV (2016) Structure, phase composition, and strengthening of cast Al–Ca–Mg–Sc alloys. Phys Met Metallogr 117(2):188–194. https://doi.org/10.1134/S0031918X16020046

Pouraliakbar H, Pakbaz M, Firooz S, Jandaghi MR, Khalaj G (2016) Study on the dynamic and static softening phenomena in Al–6Mg alloy during two-stage deformation through interrupted hot compression test. Measurement 77:50–53. https://doi.org/10.1016/j.measurement.2015.08.033

Reza Jandaghi M, Pouraliakbar H, Saboori A (2019) Effect of second-phase particles evolution and lattice transformations while ultrafine graining and annealing on the corrosion resistance and electrical conductivity of Al–Mn–Si alloy. Mater Res Expr 6(10):1065D9. https://doi.org/10.1088/2053-1591/ab37d5

Baranov VN, Sidelnikov SB, Zenkin EY, Konstantinov IL, Lopatina ES, Yakivyuk OV, Voroshilov DS, Belokonova IN, Frolov VA (2019) Study on the influence of heat treatment modes on mechanical and corrosion properties of rolled sheet products from a new aluminum alloy, economically alloyed with scandium. Vestnik of Nosov Magnitogorsk State Techn Univ 17(1):76–81. https://doi.org/10.18503/1995-2732-2019-17-1-76-81

Baranov VN, Zenkin EY, Konstantinov IL, Sidelnikov SB (2019) The research of the cold rolling modes for plates of aluminum alloy sparingly doped with scandium. Non-ferrous Metals 2:48–52. https://doi.org/10.17580/nfm.2019.02.08

Dovzhenko NN, Rushchits SV, Dovzhenko IN, Yurev PO (2019) Understanding the behaviour of aluminium alloy Р-1580 sparingly doped with scandium under hot deformation. Tsvetnye Metally 9:80–86. https://doi.org/10.17580/tsm.2019.09.13

Baranov VN, Sidelnikov SB, Bezrukikh AI, Zenkin EY (2017) Research of rolling regimes and mechanical properties of cold-rolled, annealed and welded semi-finished products from experimental alloys of Al – Mg system, economically alloyed by scandium. Tsvetnye Metally 9:91–96. https://doi.org/10.17580/tsm.2017.09.13

Baranov VN, Sidelnikov SB, Zenkin EY, Bezrukikh AI, Konstantinov IL, Sokolov RE, Voroshilov DS, Belokonova IN, Yakivyuk OV (2017) Study of the mechanical properties of semi-finished products from aluminum-scandium alloy. Bull Tula State Univ 11(1):147–153

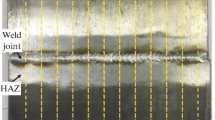

Dovzhenko NN, Demchenko AI, Bezrukikh AA, Dovzhenko IN, Baranov VN, Orelkina TA, Dementeva IS, Voroshilov DS, Gaevskiy VN, Lopatina ES (2021) Mechanical properties and microstructure of multi-pass butt weld of plates made of Al-Mg-Zr alloy sparingly doped with scandium. Int J Adv Manuf Technol 113:785–805. https://doi.org/10.1007/s00170-021-06665-8

Baranov VN, Sidelnikov SB, Zenkin EY, Voroshilov DS (2018) Development of fabrication modes of deformed semifinished products from the experimental scandium-containing aluminum alloy and investigation into their mechanical properties. Russ J Non-Ferrous Metals 59(1):62–66

Konstantinov IL, Baranov VN, Sidelnikov SB, Kulikov BP, Bezrukikh AI, Frolov VF, Orelkina TA, Voroshilov DS, Yuryev PO, Belokonova IN (2020) Investigation of the structure and properties of cold-rolled strips from experimental alloy 1580 with a reduced scandium content. Int J Adv Manuf Technol 109(1-2):443–450. https://doi.org/10.1007/s00170-020-05681-4

Dovzhenko IN, Dovzhenko NN, Sidelnikov SB, Konstantinov IL (2017) 3D modelling of the large-capacity ingots of an Al - Mg system aluminium alloy doped with scandium rolling process. Non-Ferrous Metals 43(2):60–64. https://doi.org/10.17580/nfm.2017.02.11http://rudmet.net/media/articles/Article_NFM_02_17_pp.60-64_1.pdf

Konstantinov IL, Baranov VN, Sidelnikov SB, Arnautov AD, Voroshilov DS, Dovzenko NN, Zenkin EY, Bezrukikh AI, Dovzenko IN, Yuryev PO (2021) Investigation of cold rolling modes of 1580 alloy by the method of computer simulation. Int J Adv Manuf Technol 112(7):1965–1972. https://doi.org/10.1007/s00170-020-06570-6

Mann VK, Sidelnikov SB, Konstantinov IL, Baranov VN, Dovzhenko IN, Voroshilov DS, Lopatina ES, Yakivyuk OV, Belokonova IN (2019) Modeling and investigation of the process of hot rolling of large-sized ingots from aluminum alloy of the Al-Mg system, economically alloyed by scandium. Mater Sci Forum 943:58–65. https://doi.org/10.4028/www.scientific.net/MSF.943.58

Konstantinov IL, Baranov VN, Sidelnikov SB, Zenkin EY, Yuryev PO, Belokonova IN (2020) Influence of rolling and annealing modes on properties of sheet semifinished products made of wrought aluminum alloy 1580. Russ J Non-Ferrous Metals 61:641–645. https://doi.org/10.3103/S1067821220060115

Li M, Pan Q, Shi Y, Xue S, Xiang H (2017) High strain rate superplasticity in an Al–Mg–Sc–Zr alloy processed via simple rolling. Mater Sci Eng А687:298–305. https://doi.org/10.1016/j.msea.2017.01.091

Koryagin YD, Il'in SI (2017) Recrystallization features of deformable aluminium-magnesium alloys with scandium. Bull South Ural State Univ Ser “Metallurgy” 17(1):65–72

Knipling KE, Seidman DN, Dunand DC (2011) Ambient- and high-temperature mechanical properties of isochronally aged Al–0.06Sc, Al–0.06Zr and Al–0.06Sc–0.06Zr (at.%) alloys. Acta Mater 59:943–954. https://doi.org/10.1016/j.actamat.2010.10.017

Xie J, Chen XP, Mei L, Huang GJ, Liu Q (2021) Investigation of the hardening behavior during recrystallization annealing in Al-Mg-Sc alloy. J Alloys Compd 859:157807. https://doi.org/10.1016/j.jallcom.2020.157807

Jiang J, Jiang F, Zhang M, Tang Z, Tong M (2020) Effect of continuity of annealing time on the recrystallization behavior of Al-Mg-Mn-Sc-Zr alloy. Mater Lett 275:128208. https://doi.org/10.1016/j.matlet.2020.128208

Jiang J, Jiang F, Zhang M, Tang Z, Tong M (2020) Al3(Sc, Zr) precipitation in deformed Al-Mg-Mn-Sc-Zr alloy: effect of annealing temperature and dislocation density. J Alloys Compd 831:154856. https://doi.org/10.1016/j.jallcom.2020.154856

Vlach M, Stulíková I, Smola B, Zaludová N, Cerná J (2010) Phase transformations in isochronally annealed mould-cast and cold-rolled Al–Sc–Zr-based alloy. J Alloys Compd 149:243–148. https://doi.org/10.1016/j.jallcom.2009.11.126

Belov NA (2010) Phase composition of industrial and promising aluminum alloys. MISiS, Moscow

Funding

The research was carried out within the state assignment of Ministry of Science and Higher Education of the Russian Federation (scientific topic code FSRZ-2020-0011).

Author information

Authors and Affiliations

Contributions

The authors declare that they are all participants in the work and none of them performed only administrative functions.

Corresponding author

Ethics declarations

Ethical approval

The work contains no libelous or unlawful statements, does not infringe on the rights of others, or contains material or instructions that might cause harm or injury.

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuryev, P.O., Baranov, V.N., Orelkina, T.A. et al. Investigation the structure in cast and deformed states of aluminum alloy, economically alloyed with scandium and zirconium. Int J Adv Manuf Technol 115, 263–274 (2021). https://doi.org/10.1007/s00170-021-07206-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07206-z