Abstract

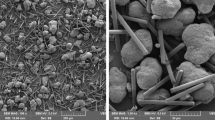

The process parameters on selective laser sintering (SLS) have a strong effect on part quality. To better understand SLS of composite materials, this study focuses on the influence of laser scan angle and oxygen gas interaction on the mechanical properties, morphology, and joining mechanisms of laser-sintered aluminum-filled polyamide-12 single-layer specimens at room temperature. The results show that the strength and ductility increase with a higher laser scan angle (e.g., near 60°), and the oxygen concentration in the chamber shows a small effect on the elongation. No changes in the morphology and internal structure of the specimens were observed under a different set of process parameters. Additionally, two failure mechanisms were observed; a ductile failure that occurs when particles are well-blended where the metallic particles work effectively hindering crack propagations, and a brittle failure when local amounts of metallic particles are low.

Similar content being viewed by others

References

Bernard A, Taillandier G, Karunakaran KP (2009) Evolutions of rapid product development with rapid manufacturing: concepts and applications. Int J Rapid Manuf 1:3–18. https://doi.org/10.1504/IJRAPIDM.2009.028929

Negi S, Dhiman S, Sharma RK (2013) Basics, applications and future of additive manufacturing technologies: a review. J Manuf Technol Res 5:75–96

Negi S, Sharma RK, Dhiman S (2014) Experimental investigation of SLS process for flexural strength improvement of PA-3200GF Parts. Mater Manuf Process 30:644–653. https://doi.org/10.1080/10426914.2014.994750

Kalpakjian S, Schmid S (2014) Manufacturing engineering and technology, 7th edn. Pearson, Boston

EOS GmbH (2012) Alumide data sheet

Tiwari SK, Pande S, Agrawal S, Bobade SM (2015) Selection of selective laser sintering materials for different applications. Rapid Prototyp J 21:630–648. https://doi.org/10.1108/RPJ-03-2013-0027

Goodridge RD, Tuck CJ, Hague RJM (2012) Laser sintering of polyamides and other polymers. Prog Mater Sci 57:229–267. https://doi.org/10.1016/j.pmatsci.2011.04.001

Kruth JP, Levy G, Klocke F, Childs THC (2007) Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann Manuf Technol 56:730–759. https://doi.org/10.1016/j.cirp.2007.10.004

Caulfield B, McHugh PE, Lohfeld S (2007) Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J Mater Process Technol 182:477–488. https://doi.org/10.1016/j.jmatprotec.2006.09.007

Mazzoli A, Moriconi G, Pauri MG (2007) Characterization of an aluminum-filled polyamide powder for applications in selective laser sintering. Mater Des 28:993–1000. https://doi.org/10.1016/j.matdes.2005.11.021

Bassoli E, Gatto A, Iuliano L (2012) Joining mechanisms and mechanical properties of PA composites obtained by selective laser sintering. Rapid Prototyp J 18:100–108. https://doi.org/10.1108/13552541211212087

Stoia DI, Linul E, Marsavina L (2019) Influence of manufacturing parameters on mechanical properties of porous materials by selective laser sintering. Materials (Basel) 12:871. https://doi.org/10.3390/ma12060871

Tarasova A, Wegner A, Witt G (2019) Approach to defining the maximum filler packing volume fraction in laser sintering on the example of aluminum-filled polyamide 12. In: 30th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference. pp 977–986

Bochnia J, Blasiak S (2020) Stress relaxation and creep of a polymer-aluminum composite produced through selective laser sintering. Polymers (Basel) 12:830. https://doi.org/10.3390/polym12040830

Valkot EI, Chiklis CK (1965) Effects of thermal exposure on the physicochemical properties of polyamides. J Appl Polym Sci 9:2855–2877. https://doi.org/10.1002/app.1965.070090820

Wudy K, Drummer D, Kühnlein F, Drexler M (2014) Influence of degradation behavior of polyamide 12 powders in laser sintering process on produced parts. AIP Conf Proc 1593:691–695. https://doi.org/10.1063/1.4873873

Kummert C, Josupeit S, Schmid H-J (2017) Thermoplastic elastomer part color as function of temperature histories and oxygen atmosphere during selective laser sintering. J Miner Met Mater Soc 70:425–430. https://doi.org/10.1007/s11837-017-2658-2

Hariharan K, Arumaikkannu G, Ramkumar T, Selvakumar M (2020) Material stability investigation of polyamide material before and after laser sintering. Int J Polym Anal Charact 25:158–165. https://doi.org/10.1080/1023666X.2020.1766798

Zarringhalam H, Hopkinson N, Kamperman NF, de Vlieger JJ (2006) Effects of processing on microstructure and properties of SLS Nylon 12. Mater Sci Eng A 435–436:172–180. https://doi.org/10.1016/j.msea.2006.07.084

Alamos Domeyko FJ (2018) Effect of scanning direction, atmospheric oxygen and laser power on mechanical properties of selective laser sintering (SLS) of aluminum-filled polyamide monolayers. Pontificia Universidad Católica de Chile

Montgomery DC (2012) Design and analysis of experiments, Eight edn. Wiley, Hoboken

Kim H, Park E, Kim S et al (2017) Experimental study on mechanical properties of single- and dual-material 3d printed products. Procedia Manuf 10:887–897. https://doi.org/10.1016/j.promfg.2017.07.076

Sabelle M, Walczak M, Ramos-Grez J (2018) Scanning pattern angle effect on the resulting properties of selective laser sintered monolayers of Cu-Sn-Ni powder. Opt Lasers Eng 100:1–8. https://doi.org/10.1016/j.optlaseng.2017.06.028

Negi S, Dhiman S, Sharma RK (2015) Determining the effect of sintering conditions on mechanical properties of laser sintered glass filled polyamide parts using RSM. Meas J Int Meas Confed 68:205–218. https://doi.org/10.1016/j.measurement.2015.02.057

Negi S, Dhiman S, Sharma RK (2014) Basics and applications of rapid prototyping medical models. Rapid Prototyp J 20:256–267. https://doi.org/10.1108/RPJ-07-2012-0065

Pavlov NN, Kudryavtseva GA, Abramova IM, Vasil'eva VA, Zezina LA, Kazaryan LG (1987) Physical transformations and change in mechanical properties on thermal ageing of aliphatic polyamides. Polym Sci USSR 29:967–973. https://doi.org/10.1016/0032-3950(87)90477-1

Dong W, Gijsman P (2010) Influence of temperature on the thermo-oxidative degradation of polyamide 6 films. Polym Degrad Stab 95:1054–1062. https://doi.org/10.1016/j.polymdegradstab.2010.02.030

Su KH, Lin JH, Lin CC (2007) Influence of reprocessing on the mechanical properties and structure of polyamide 6. J Mater Process Technol 192–193:532–538. https://doi.org/10.1016/j.jmatprotec.2007.04.056

Josupeit S, Schmid HJ (2017) Experimental analysis and modeling of local ageing effects during laser sintering of polyamide 12 in regard to individual thermal histories. J Appl Polym Sci 134. https://doi.org/10.1002/app.45435

Carraher CE (2003) Polymer chemistry, Sixth edn. Marcel Dekker, Inc, New York

Crist B, Schultz JM (2016) Polymer spherulites: a critical review. Prog Polym Sci 56:1–63. https://doi.org/10.1016/j.progpolymsci.2015.11.006

Acknowledgements

Gratitude is extended to DICTUC SA for the technical support in the design and build of the chamber and tensile testing, and Dr. Glen Niebur and Dr. Steven Schmid for access to the Micro CT and laboratory facilities at the University of Notre Dame.

Funding

The authors received financial support from the University of Notre Dame and Pontificia Universidad Católica de Chile (UND-PUC) Seed Fund for the SEM and EDS electronic microscope analysis, and from ANID FONDECYT project #1201068.

Author information

Authors and Affiliations

Contributions

Fernando J. Alamos: original idea of the paper, literature review, design of experiments, experimental setup, data generation: microstructural evaluation, tensile testing, analysis of variance, manuscript writing. Jorge Andrés Ramos-Grez: original conceptualization of the paper, close supervision, and guidance during the research process, critical advice, data generation: scanning electron microscopy and energy-dispersive spectroscopy data collection, manuscript proofreading, and funding. Loreto M. Valenzuela: literature review, critical advice, and manuscript proofreading.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

All the authors involved have agreed to participate in this submitted article.

Consent for publication

All the authors involved in this manuscript give full consent for publication of this submitted article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alamos, F.J., Ramos-Grez, J.A. & Valenzuela, L.M. Effect of laser scanning angle and atmospheric oxygen on mechanical properties and microstructural morphology of selective laser-sintered aluminum-filled polyamide monolayers. Int J Adv Manuf Technol 114, 3449–3458 (2021). https://doi.org/10.1007/s00170-021-07120-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07120-4