Abstract

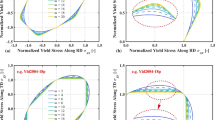

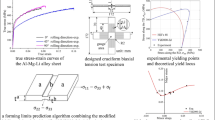

This study proposed a crystallographic texture-based multi-scale modelling framework to predict mechanical anisotropy of textured aluminium alloy sheet. The multi-scale scheme was constructed by the combination of a full-field crystal plasticity model in mesoscopic scale and a newly developed phenomenological yield function in continuum scale. In this approach, the mechanical anisotropy of materials is directly obtained from crystal plasticity (CP) modelling without extensive directional tensile tests. The results show that the multi-scale scheme predicted earing profiles coincide well with experimental measurements. This multi-scale modelling could be utilised to design an optimised blank shape with minimum earing for the deep-drawn component, and a convoluted cut-edge was devised accordingly.

Similar content being viewed by others

Availability of data and materials

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Saxena RK, Dixit PM (2010) Prediction of flange wrinkling in deep drawing process using bifurcation criterion. J Manuf Process 12(1):19–29

Hu J, Marciniak Z, Duncan J (2002) Mechanics of sheet metal forming. Elsevier, Amsterdam

Ma J, Welo T (2021) Analytical springback assessment in flexible stretch bending of complex shapes. Int J Mach Tools Manuf 160:103653

Welo T, Ringen G, Ma J (2020) An overview and evaluation of alternative forming processes for complex aluminium products. Procedia Manuf 48:82–89. 48th SME North American Manufacturing Research Conference, NAMRC 48

Ding Z, Sun G, Guo M, Jiang X, Li B, Liang SY (2020) Effect of phase transition on micro-grinding-induced residual stress. J Mater Process Technol 281:116647

Fischer P, Heingǎrtner J, Duncan S, Hora P (2020) On part-to-part feedback optimal control in deep drawing. J Manuf Process 50:403–411

Rivas-Menchi A, Medellín-Castillo HI, Dirk F, García-Zugasti PJ (2018) Performance evaluation of analytical expressions for cylindrical and rectangular deep drawing force estimation. J Manuf Process 36:340–350

Kohar CP, Mohammadi M, Mishra RK, Inal K (2016) The effects of the yield surface curvature and anisotropy constants on the axial crush response of circular crush tubes. Thin-Walled Struct 106:28–50

Basak S, Panda SK (2018) Implementation of yld96 anisotropy plasticity theory for estimation of polar effective plastic strain based failure limit of pre-strained thin steels. Thin-Walled Struct 126:26–37. Special Issue on Plasticity and Impact Mechanics (IMPLAST 2016)

Banabic D, Carleer B, Comsa DS, Kam E, Krasovskyy A, Mattiasson K, Sester M, Sigvant M, Zhang X (2010) Sheet metal forming processes: Constitutive modelling and numerical simulation

Liu W, Chen BK, Pang Y (2018) A new temperature-dependent anisotropic constitutive model for predicting deformation and spring-back in warm deep drawing of automotive AA5086-H111 aluminium alloy sheet. Int J Adv Manuf Technol 97:3407–3421

Dick RE, Yoon JW (2018) Plastic anisotropy and failure in thin metal: Material characterization and fracture prediction with an advanced constitutive model and polar EPS (effective plastic strain) fracture diagram for AA 3014-H19. Int J Solids Struct 151:195–213

Liu W, Chen BK (2018) Sheet metal anisotropy and optimal non-round blank design in high-speed multi-step forming of aa3104-h19 aluminium alloy can body. Int J Adv Manuf Technol 95(9-12):4265–4277

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc London Series A Math Phys Sci 193(1033):281–297

Shen F, Münstermann S, Lian J (2021) Forming limit prediction by the Marciniak-Kuczynski model coupled with the evolving non-associated Hill48 plasticity model. J Mater Process Technol 287:116384

Barlat F, Brem JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F, Choi SH, Chu E (2003) Plane stress yield function for aluminum alloy sheets - Part 1: Theory. Int J Plast 19 (9):1297–1319

Barlat F, Aretz H, Yoon JW, Karabin ME, Brem JC, Dick RE (2005) Linear transfomation-based anisotropic yield functions. Int J Plast 21(5):1009–1039

Yoon JW, Barlat F, Dick RE, Karabin ME (2006) Prediction of six or eight ears in a drawn cup based on a new anisotropic yield function. Int J Plast 22(1):174–193

Singh A, Basak S, P.S. LP, Roy GG, Jha MN, Mascarenhas M, Panda SK (2018) Prediction of earing defect and deep drawing behavior of commercially pure titanium sheets using cpb06 anisotropy yield theory. J Manuf Process 33:256–267

Aretz H, Engler O (2020) Accuracy analysis of earing compensation procedures. Int J Solids Struct(xxxx)

Pang Y, Chen BK, Liu W (2019) An investigation of plastic behaviour in cold-rolled aluminium alloy AA2024-T3 using laser speckle imaging sensor. Int J Adv Manuf Technol 103(5):2707–2724

Izadpanah S, Ghaderi SH, Gerdooei M (2016) Material parameters identification procedure for BBC2003 yield criterion and earing prediction in deep drawing. Int J Mech Sci 115-116:552–563

Min J, Carsley JE, Lin J, Wen Y, Kuhlenkötter B (2016) A non-quadratic constitutive model under non-associated flow rule of sheet metals with anisotropic hardening: Modeling and experimental validation. Int J Mech Sci 119:343–359

Najafi A, Marin EB, Rais-Rohani M (April 2012) Concurrent multi-scale crush simulations with a crystal plasticity model. Thin-Walled Struct 53:176–187

Kohar CP, Brahme A, Hekmat F, Mishra RK, Inal K (2019) A computational mechanics engineering framework for predicting the axial crush response of aluminum extrusions. Thin-Walled Struct 140:516–532

Taylor GI (1938) Plastic strain in metals. J Inst Metals 62:307–324

Bishop JFW, Hill R (1951) Xlvi. a theory of the plastic distortion of a polycrystalline aggregate under combined stresses. Lond Edinburgh Dublin Philos Mag J Sci 42(327):414–427

Houtte PV, Delannay L, Kalidindi SR (2002) Comparison of two grain interaction models for polycrystal plasticity and deformation texture prediction. Int J Plast 18(3):359–377

Sachtleber M, Zhao Z, Raabe D (2002) Experimental investigation of plastic grain interaction. Mater Sci Eng A 336(1):81–87

Hutchinson JW (1976) Bounds and self-consistent estimates for creep of polycrystalline materials. Proc R Soc Lond A Math Phys Sci 348(1652):101–127

Molinari A, Canova GR, Ahzi S (1987) A self consistent approach of the large deformation polycrystal viscoplasticity. Acta Metall 35(12):2983–2994

Lebensohn RA, Tomé CN (1993) A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: Application to zirconium alloys. Acta Metallurgica et Materialia 41(9):2611–2624

Engler O, Mertens N, van Dam P (2011) Texture-based design of a convoluted cut-edge for earing-free beverage cans. J Mater Process Technol 211(7):1278–1284

Lebensohn RA, Kanjarla AK, Eisenlohr P (2012) An elasto-viscoplastic formulation based on fast fourier transforms for the prediction of micromechanical fields in polycrystalline materials. Int J Plast 32-33:59–69

Roters F, Eisenlohr P, Hantcherli L, Tjahjanto DD, Bieler TR, Raabe D (2010) Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater 58(4):1152–1211

Zhang K, Holmedal B, Hopperstad OS, Dumoulin S, Gawad J, Van Bael A, Van Houtte P (2015) Multi-level modelling of mechanical anisotropy of commercial pure aluminium plate: Crystal plasticity models, advanced yield functions and parameter identification. Int J Plast 66:3–30

Raabe D, Sachtleber M, Zhao Z, Roters F, Zaefferer S (2001) Micromechanical and macromechanical effects in grain scale polycrystal plasticity experimentation and simulation. Acta Mater 49(17):3433–3441

Shanthraj P, Eisenlohr P, Diehl M, Roters F (2015) Numerically robust spectral methods for crystal plasticity simulations of heterogeneous materials. Int J Plast 66:31–45

Eisenlohr P, Diehl M, Lebensohn RA, Roters F (2013) A spectral method solution to crystal elasto-viscoplasticity at finite strains. Int J Plast 46:37–53

Han F, Diehl M, Roters F, Raabe D (2020) Using spectral-based representative volume element crystal plasticity simulations to predict yield surface evolution during large scale forming simulations. J Mater Process Technol 277(July 2019):116449

Zhang H, Diehl M, Roters F, Raabe D (2016) A virtual laboratory using high resolution crystal plasticity simulations to determine the initial yield surface for sheet metal forming operations. Int J Plast 80:111–138

Hutchinson JW (1976) Bounds and self-consistent estimates for creep of polycrystalline materials. Proc R Soc Lond A 348(1652):101–127

Brown SB, Kim KH, Anand L (1989) An internal variable constitutive model for hot working of metals. Int J Plast 5(2):95–130

Peirce D, Asaro RJ, Needleman A (1983) Material rate dependence and localized deformation in crystalline solids. Acta metallurgica 31(12):1951–1976

Roters F, Diehl M, Shanthraj P, Eisenlohr P, Reuber C, Wong SL, Maiti T, Ebrahimi A, Hochrainer T, Fabritius H-O et al (2019) Damask–the düsseldorf advanced material simulation kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput Mater Sci 158:420–478

Aretz H, Barlat F (2013) New convex yield functions for orthotropic metal plasticity. Int J Non-Linear Mech 51:97–111

Plunkett B, Cazacu O, Barlat F (2008) Orthotropic yield criteria for description of the anisotropy in tension and compression of sheet metals. Int J Plast 24(5):847–866

Halilovic M, Vrh M, Stok B (2009) Nice an explicit numerical scheme for efficient integration of nonlinear constitutive equations. Math Comput Simul 80(2):294–313

Halilovič M, Vrh M, Štok B (2013) Nice h: A higher-order explicit numerical scheme for integration of constitutive models in plasticity. Eng Comput 29(1):55–70

ASTM-E8-E8M13 (2013) Standard test method for tensiontesting of metallic materials. ASTM International, West Conshohocken

ASTM-B831-05 (2005) Standard test method for shear testingof thin aluminum alloy products. ASTM International, West Conshohocken

Yin Q, Zillmann B, Suttner S, Gerstein G, Biasutti M, Tekkaya AE, Wagner MF-X, Merklein M, Schaper M, Halle T, Brosius A (2014) An experimental and numerical investigation of different shear test configurations for sheet metal characterization. Int J Solids Struct 51(5):1066–1074

Yoon JW, Dick RE, Barlat F (2011) A new analytical theory for earing generated from anisotropic plasticity. Int J Plast 27(8):1165–1184

Acknowledgements

The authors acknowledge use of facilities within the Monash Centre for Electron Microscopy, Monash University.

Funding

This work is sponsored by National Natural Science Foundation of China [Grant Number: 12002211] and Shanghai Sailing Program [No. 20YF1432700].

Author information

Authors and Affiliations

Contributions

1. Wencheng Liu: conceptualisation, data collection, formal analysis, investigation, methodology, software, writing–original draft preparation

2. Yong Pang: data collection, investigation, resources, validation, writing–review and editing

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, W., Pang, Y. A multi-scale modelling framework for anisotropy prediction in aluminium alloy sheet and its application in the optimisation of the deep-drawing process. Int J Adv Manuf Technol 114, 3401–3417 (2021). https://doi.org/10.1007/s00170-021-07060-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07060-z