Abstract

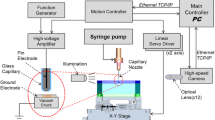

Electrohydrodynamic (EHD) printing is a novel printing technology with high printing resolution, making it suitable for applications such as tissue engineering and micro/nanomanufacturing. Inkjets from EHD fall on the substrate either in the continuous or drop-on-demand (D-O-D) mode. In this research, the D-O-D-based EHD printing process was used to print micro droplets of bioink assisted by a pulse electric field. A 2% (g/mL) sodium alginate solution was used as the bioink. A general full factorial design was used to analyze and observe the relation between the bioink droplet quality and the EHD process parameters. The diameter of the droplet, droplet generation rate, distance between two droplets, and the droplet consistency are the four major responses to evaluate the printing quality. The EHD process parameters, offset voltage, pulse width, and frequency, are the three regressor variables. After conducting the data analysis, it is observed that the higher frequency and the lower voltage produced the smaller droplet diameter, higher droplet generation rate, and nearer distance among the droplets. However, this increased the variance in the droplet patterns thus reducing the consistency of the printing process. It was also found that pulse width had marginal significance on the quality of printed drops. From the data analysis, four regression models were developed to aid in finding the parameter combinations to print 2% sodium alginate at a desired droplet diameter, droplet generation rate, and droplet distance. This proposed model can be used as a guideline for EHD bioprinting experimental setup, and it will significantly reduce the efforts to determine the optimal process parameters.

Similar content being viewed by others

Data availability

The authors confirm that material supporting the findings of this work is available within the article.

References

Aggas JR, Abasi S, Phipps JF, Podstawczyk DA, Guiseppi-Elie A (2020) Microfabricated and 3-D printed electroconductive hydrogels of PEDOT:PSS and their application in bioelectronics. Biosens Bioelectron 168:112568

Alleyne A, Barton K, Mishra S, Ferreira P, Rogers J (2013) U.S Patent No. US 8562095 B2.

Ball AK, Das R, Roy SS, Kisku DR (2020) Modeling of EHD inkjet printing performance using soft computing-based approaches. Soft Comput:571–589. https://doi.org/10.1007/s00500-019-04202-0

Belalia F, Djelali N-E (2014) Rheological properties of sodium alginate solutions. Rev Roum Chim 59(2):135–145

Chahal D, Ahmadi A, Cheung KC (2012) Improving piezoelectric cell printing accuracy and reliability through neutral buoyancy of suspensions. Biotechnol Bioeng 109:2932–2940. https://doi.org/10.1002/bit.24562

Choi D, Smith IR (1998) U.S Patent No. 5838349.

Gasperini L, Maniglio D, Motta A, Migliaresi C (2015) An electrohydrodynamic bioprinter for alginate hydrogels containing living cells. Tissue Eng C 21:123–132. https://doi.org/10.1089/ten.tec.2014.0149

Heo DN, Lee S-J, Timsina R, Qiu X, Castro NJ, Zhang LG (2019) Development of 3D printable conductive hydrogel with crystallized PEDOT:PSS for neural tissue engineering. Mater Sci Eng C 99:582–590. https://doi.org/10.1016/j.msec.2019.02.008

Jammalamadaka U, Tappa K (2018) Recent advances in biomaterials for 3d printing and tissue engineering. J Funct Biomater 9(1). https://doi.org/10.3390/jfb9010022

Kyser EL, Sears SB (1976) U.S. Patent No. 3946398A.

Langer R, Vacanti J (1993) Tissue engineering. Science 260:920–926

Mishra S, Barton KL, Alleyne AG, Ferreira PM, Rogers JA (2010) High speed and drop-on-demand printing with a pulsed electrohydrodynamic jet. J Micromech Microeng:20

Moghadam H, Samimi M, Samimi A, Khorram M (2010) Electrospray modeling of highly viscous and non-Newtonian liquids. J Appl Polym Sci 118:1288. https://doi.org/10.1002/app.32302

Mohammadi K, Movahhedy MR, Khodaygan S (2019) A multiphysics model for analysis of droplet formation in electrohydrodynamic 3D printing process. J Aerosol Sci 135:72–85. https://doi.org/10.1016/j.jaerosci.2019.05.001

Nair LS, Laurencin C (2005) Polymers as biomaterials for tissue engineering and controlled drug delivery. Tissue Eng I 102:47–90. https://doi.org/10.1007/b137240

Park J-U, Hardy M, Kang SJ, Barton K, Adair K, Mukhopadhyay DK, Lee CY, Strano MS, Alleyne AG, Georgiadis JG, Ferreira PM, Rogers JA (2007) High-resolution electrohydrodynamic jet printing. Nat Mater 6:782–789. https://doi.org/10.1038/nmat1974

Raje PV, Murmu NC (2014) A review on electrohydrodynamic-inkjet printing technology. Int J Emerg Technol Adv Eng 4(5):174–183. http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.644.1630&rep=rep1&type=pdf

Rimann M, Bono E, Annaheim H, Bleisch M, Graf-Hausner U (2015) Standardized 3D bioprinting of soft tissue. J Lab Automat:1–14. https://doi.org/10.1177/2211068214567146

Rune E (1951) U.S. Patent No. 2566443.

Shi J, Song J, Song B, Lu WF (2019) Multi-objective optimization design through machine learning for drop on demand bioprinting. Engineering 5:586–593

Sweet RG (1965) High frequency recording with electrostatically deflected ink jets. Rev Sci Instrum 36:131–136. https://doi.org/10.1063/1.1719502

Tae HH, Kim Y-J, Chung H, Ryu W (2016) Motionless electrohydrodynamic (EHD) printing of biodegradable polymer micro patterns. Microelectron Eng 161:43–51. https://doi.org/10.1016/j.mee.2016.03.039

Taylor GI (1964) Disintegration of water drops in electric field. Proc R Soc Lond 280:383–397. https://doi.org/10.1098/rspa.1964.0151

Vijayavenkataraman S, Zhang S, Lu WF, Fuh JY (2018) Electrohydrodynamic-jetting (EHD-jet) 3D-printed functionally graded scaffolds for tissue engineering applications. J Mater Res 33(14):1999–2011. https://doi.org/10.1557/jmr.2018.159

Xu C, Chai W, Huang Y, Markwald RR (2012) Scaffold-free inkjet printing of three-dimensional zigzag cellular tubes. Biotechnol Bioeng 109:3152–3160. https://doi.org/10.1002/bit.24591

Xu C, Zhang M, Huang Y, Ogale A, Fu J, Markwald RR (2014) Study of droplet formation process during drop-on-demand. Langmuir. 30:9130–9138

Zoltan SI (1972) U.S. Patent No. 3683212A.

Zhang X, Jiang X, Zhang Z, Qin H (2021) Fabrication of silver microstructures via electrohydrodynamic inkjet printing as customizable X-ray marker in bio-structure for biomedical diagnostic imaging. Int J Adv Manuf Technol 114(1-2):241–250

Yang YJ, Kim HC, Sajid M, Kim SW, Aziz S, Choi YS, Choi KH (2018) Drop-on-Demand Electrohydrodynamic Printing of High Resolution Conductive Micro Patterns for MEMS Repairing. Int J Precis Eng Manuf 19(6):811–819

Zębala W, Kowalczyk R (2015) Estimating the effect of cutting data on surface roughness and cutting force during WC-Co turning with PCD tool using Taguchi design and ANOVA analysis. Int J Adv Manuf Technol 77 (9–12):2241–2256

Montgomery DC (2017) Design and analysis of experiments. John wiley & sons

Kara F, Takmaz A (2019) Optimization of cryogenic treatment effects on the surface roughness of cutting tools. Mater Test 61 (11):1101–1104

Le Coz G, Piquard R, Acunto AD, Bouscaud D, Fischer M, Laheurte P (2020) Precision turning analysis of Ti-6Al-4V skin produced by selective laser melting using a design of experiment approach. J Adv Manuf Technol 110(5-6):1615–1625

Funding

This work is supported by the US Department of Defense Manufacturing Engineering Education Program (MEEP) program under the award # N00014-19-1-2728, the Bose Family Donation to the Department of Manufacturing and Industrial Engineering at the UTRGV, and the start-up fund at the Mississippi State University.

Author information

Authors and Affiliations

Contributions

Experiment: Taieba Tuba Rahman, Md Shakil Arman, Victoria Perez; Data Analysis: Taieba Tuba Rahman, Md Shakil Arman, Ben Xu, Jianzhi Li; Writing (original draft preparation): Taieba Tuba Rahman, Md Shakil Arman; Writing (review and editing): Ben Xu, Jianzhi Li, Victoria Perez.

Corresponding authors

Ethics declarations

Ethical approval

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent to participate

Not applicable. The article involves no studies on humans.

Consent to publish

Not applicable. The article involves no studies on humans.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rahman, T.T., Arman, M.S., Perez, V. et al. Analysis of the operating conditions of pulse electric field–assisted EHD for sodium alginate printing using design of experiment approach. Int J Adv Manuf Technol 115, 2037–2047 (2021). https://doi.org/10.1007/s00170-021-07042-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07042-1