Abstract

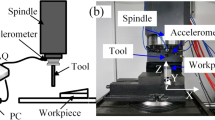

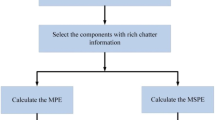

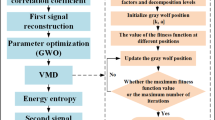

In the milling process, chatter is easy to occur and has a very adverse impact on the quality of the workpiece and the production efficiency. A chatter feature extraction method based on optimized variational mode decomposition (OVMD) and multi-scale permutation entropy (MPE) was proposed to solve the problem that it is difficult to detect the machining chatter state during milling. The methodology presented in this article allows the occurrence of machining chatter to be effectively identified through real-time digital signal processing and analysis. First, in order to solve the problem of variational mode decomposition (VMD) parameter selection, an automatic selection method based on particle swarm optimization (PSO) and the maximum crest factor of the envelope spectrum (CE) was proposed. Then, the decomposed signal was reconstructed based on the energy ratio. In order to solve the problem that the single-scale permutation entropy (PE) cannot detect milling chatter well, the MPE was introduced to detect milling chatter. Finally, experimental verification was carried out, and the MPE of the reconstructed signals at different scales was extracted and analyzed. The results show that using the OVMD algorithm to process the signals can significantly improve the discrimination of MPE. With the increase of the scale factor, the MPE of the milling signals tends to decrease. At the same time, MPE is better than single-scale PE in chatter detection, and the MPE at scale factor of 4 is more conducive to chatter detection.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared for the time being. Data will be made available upon request.

References

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376. https://doi.org/10.1016/j.ijmachtools.2011.01.001

Wang ZX, Liu XL, Li MY, Liang SY, Wang LH, Li YQ, Meng BY (2020) Intelligent monitoring and control technology of cutting chatter. J Mech Eng 56(24):1–23. https://doi.org/10.3901/JME.2020.24.001

Ye J, Feng PF, Xu C, Ma Y, Huang SG (2018) A novel approach for chatter online monitoring using coefficient of variation in machining process. Int J Adv Manuf Technol 96:287–297. https://doi.org/10.1007/s00170-017-1544-y

Fekrmandi H, Unal M, Baghalian A, Tashakori S, Oyola K, Alsenawi A, Tansel I (2016) A non-contact method for part-based process performance monitoring in end milling operations. Int J Adv Manuf Technol 83(1-4):13–20. https://doi.org/10.1007/s00170-015-7523-2

Sun YX, Zhuang CG, Xiong ZH (2015) A scale factor-based interpolated DFT for chatter frequency estimation. IEEE Trans Instrum Meas 64(10):2666–2678. https://doi.org/10.1109/tim.2015.2421711

Zhang CL, Li B, Chen BQ, Cao HR, Zi YY, He ZJ (2015) Weak fault signature extraction of rotating machinery using flexible analytic wavelet transform. Mech Syst Signal Process 64-65:162–187. https://doi.org/10.1016/j.ymssp.2015.03.030

Wang YX, Markert R, Xiang JW, Zheng WG (2015) Research on variational mode decomposition and its application in detecting rub-impact fault of the rotor system. Mech Syst Signal Process 60-61:243–251. https://doi.org/10.1016/j.ymssp.2015.02.020

Liu J, Hu YM, Wu B, Jin C (2017) A hybrid health condition monitoring method in milling operations. Int J Adv Manuf Technol 92:2069–2080. https://doi.org/10.1007/s00170-017-0252-y

Yang K, Wang GF, Dong Y, Zhang QB, Sang LL (2019) Early chatter identification based on an optimized variational mode decomposition. Mech Syst Signal Process 115:238–254. https://doi.org/10.1016/j.ymssp.2018.05.052

Liu CF, Zhu LD, Ni CB (2018) Chatter detection in milling process based on VMD and energy entropy. Mech Syst Signal Process 105:69–182. https://doi.org/10.1016/j.ymssp.2017.11.046

Xu W, Hu JF (2021) A novel parameter-adaptive vmd method based on grey wolf optimization with minimum average mutual information for incipient fault detection. Shock Vib 2021(2):1–14. https://doi.org/10.1155/2021/6640387

Liu C, Xu WW, Gao L (2020) Identification of milling chatter based on a novel frequency-domain search algorithm. Int J Adv Manuf Technol 109:2393–2407. https://doi.org/10.1007/s00170-020-05789-7

Chen Y, Li HZ, Hou L, Bu XJ, Ye SG, Chen D (2020) Chatter detection for milling using novel p-leader multifractal features. J Intel Manuf. https://doi.org/10.1007/s10845-020-01651-5

Tran MQ, Liu MK, Tran QV (2020) Milling chatter detection using scalogram and deep convolutional neural network. Int J Adv Manuf Technol 107:1505–1516. https://doi.org/10.1007/s00170-019-04807-7

Ji YJ, Wang XB, Liu ZB, Yan ZG, Jiao L, Wang DQ, Wang JQ (2017) EEMD-based online milling chatter detection by fractal dimension and power spectral entropy. Int J Adv Manuf Technol 92(1-4):1185–1200. https://doi.org/10.1007/s00170-017-0183-7

Zhang Z, Li HG, Meng G, Tu XT, Cheng CM (2016) Chatter detection in milling process based on the energy entropy of VMD and WPD. Int J Mach Tools Manuf 108:106–112. https://doi.org/10.1016/j.ijmachtools.2016.06.002

Nair U, Krishna BM, Namboothiri VNN, Nampoori VPN (2010) Permutation entropy based real-time chatter detection using audio signal in turning process. Int J Adv Manuf Technol 46(1-4):61–68. https://doi.org/10.1007/s00170-009-2075-y

Ren JB, Sun GZ, Chen B, Luo M (2015) Multi-scale permutation entropy based on-line milling chatter detection method. J Mech Eng 51(9):206–212. https://doi.org/10.3901/JME.2015.09.206

Li XL, Ouyang GX, Liang ZH (2008) Complexity measure of motor current signals for tool flute breakage detection in end milling. Int J Mach Tools Manuf 48(3):371–379. https://doi.org/10.1016/j.ijmachtools.2007.09.008

Rusinek R, Borowiec M (2015) Stability analysis of titanium alloy milling by multiscale entropy and Hurst exponent. Eur Phys J Plus 130(10):194. https://doi.org/10.1140/epjp/i2015-15194-1

Li K, He SP, Luo B, Li B, Liu HQ, Mao XY (2019) Online chatter detection in milling process based on VMD and multiscale entropy. Int J Adv Manuf Technol 105(5):5009–5022. https://doi.org/10.1007/s00170-019-04478-4

Li K, He SP, Li B, Liu HQ, Mao XY, Shi CM (2020) A novel online chatter detection method in milling process based on multiscale entropy and gradient tree boosting. Mech Syst Signal Process 135:106385. https://doi.org/10.1016/j.ymssp.2019.106385

Yi CC, Lv Y, Dang Z (2016) A fault diagnosis scheme for rolling bearing based on particle swarm optimization in variational mode decomposition. Shock Vib 2016:1–10. https://doi.org/10.1155/2016/9372691

Zhang L, Xiong GL, Huang WY (2015) New procedure and index for the parameter optimization of complex wavelet based resonance demodulation. J Mech Eng 51(3):129–138. https://doi.org/10.3901/JME.2015.03.129

Liu C, ChengG CXH, Pang YS (2018) Planetary gears feature extraction and fault diagnosis method based on VMD and CNN. Sensors 18(5):1523. https://doi.org/10.3390/s18051523

Dragomiretskiy K, Zosso D (2014) Variational mode decomposition. IEEE Trans Signal Process 62(3):531–544. https://doi.org/10.1109/TSP.2013.2288675

Bandt C, Pompe B (2002) Permutation entropy: a natural complexity measure for time series. Phys Rev Lett 88(17):174102. https://doi.org/10.1103/physrevlett.88.174102

Yan RQ, Liu YB, Gao RX (2012) Permutation entropy: a nonlinear statistical measure for status characterization of rotary machines. Mech Syst Signal Process 29:474–484. https://doi.org/10.1016/j.ymssp.2011.11.022

Costa M, Goldberger AL, Peng CK (2002) Multiscale entropy to distinguish physiologic and synthetic RR time series. Comput Cardiol 2002:137–140. https://doi.org/10.1109/cic.2002.1166726

Zhang L, Mao ZD, Xiong GL, Cui LY (2019) Adaptive fault diagnosis of rolling bearings based on crest factor of envelope spectrum. Mech Sci Technol Aerosp Eng 38(4):507–514. https://doi.org/10.13433/j.cnki.1003-8728.20180244

Bao WJ, Tu XT, Hu Y, Li FC (2019) Envelope spectrum l-kurtosis and its application for fault detection of rolling element bearings. IEEE Trans Instrum Meas 69(5):1993–2002. https://doi.org/10.1109/TIM.2019.2917982

Appana DK, Alexander P, Jong-Myon K (2018) Reliable fault diagnosis of bearings with varying rotational speeds using envelope spectrum and convolution neural networks. Soft Comput 22:6719–6729. https://doi.org/10.1007/s00500-018-3256-0

Cabrera CG, Araujo AC, Castello DA (2017) On the wavelet analysis of cutting forces for chatter identification in milling. Adv Manuf 5(2):130–142. https://doi.org/10.1007/s40436-017-0179-4

Liu XL, Gao HN, Yue CX, Li RY, Jiang N, Yang L (2018) Investigation of the milling stability based on modified variable cutting force coefficients. Int J Adv Manuf Technol 96:2991–3002. https://doi.org/10.1007/s00170-018-1780-9

Zheng XX, Zhou GW, Ren HH, Fu Y (2017) A rolling bearing fault diagnosis method based on variational mode decomposition and permutation entropy. J Vib Shock 36(22):22–28. https://doi.org/10.13465/j.cnki.jvs.2017.22.004

Zhang J, Zhao Y, Liu M, Kong L (2019) Bearings fault diagnosis based on adaptive local iterative filtering–multiscale permutation entropy and multinomial logistic model with group-lasso. Adv Mech Eng 11(3):168781401983631. https://doi.org/10.1177/1687814019836311

Funding

This work was financially supported by:

(1) International (regional) cooperation and exchange program of national Natural Science Foundation of China under Grant No. 51720105009.

(2) National key R&D plan. Network collaborative manufacturing and smart factory special project: “Complex Tool Monitoring and Full Life Cycle Intelligent Management and Control Technology” under Grant No. 2019YFB1704800.

Author information

Authors and Affiliations

Contributions

Xianli Liu has designed the experiments, analyzed and arranged data, and wrote the manuscript; Zhixue Wang has organized the project, analyzed and arranged data, and wrote the manuscript; Maoyue Li has conducted the experiments and collected and analyzed data; Caixu Yue has conducted the experiments and collected and analyzed data; Steven Y. Liang has reviewed the manuscript; Lihui Wang has reviewed the manuscript.

Corresponding author

Ethics declarations

Ethical approval

The research does not involve human participants or animals and the authors warrant that the paper fulfills the ethical standards of the journal.

Consent to participate

It is confirmed that all the authors are aware and satisfied of the authorship order and correspondence of the paper.

Consent to publish

All the authors are satisfied that the last revised version of the paper is published without any change.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, X., Wang, Z., Li, M. et al. Feature extraction of milling chatter based on optimized variational mode decomposition and multi-scale permutation entropy. Int J Adv Manuf Technol 114, 2849–2862 (2021). https://doi.org/10.1007/s00170-021-07027-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07027-0