Abstract

This study clarified the effects of the chosen hardening model, through-thickness normal stress, and non-linear strain path on the precision of forming limit diagram (FLD). The Marciniak-Kuczynski (M-K) instability theory was employed to calculate the FLD of AA5754-O based on the different hardening models. Swift, Voce, modified Voce, Kim-Tuan, and modified Kim-Tuan hardening models were adopted to predict the forming limits, and their constant parameters were presented. Predicted FLDs indicate that modified Kim-Tuan has a better agreement with experimental data than other models. After that the influences of through-thickness normal stress on the forming limit diagram were examined. The three-dimensional stress state was converted to plane-stress condition according to the assumption that hydrostatic stress is ineffective on the plastic deformation. The results show that formability improves when normal stress increases. However, the effect of the normal stress on FLD for various hardening models is different. Due to the complexity of sheet metal forming, the strain path of the material may change during the deformation process. The results indicated that strain path has a significant effect on the FLD, and the path dependence of the forming limit stress diagram (FLSD) will be examined in detail. Finally, the forming limits were computed to analyze the effect of the normal stress on the non-linear loading path deformation. It was observed that by increasing the amount of pre-strain, the effect of the normal stress on the formability will diminish. Moreover, results showed that normal stress will affect the path dependence of the FLSD.

Similar content being viewed by others

Availability of data and materials

Not applicable

References

Keeler SP, Backhofen WA (1963) Plastic instability and fracture in sheet stretched over rigid punches. ASM Trans Quart 56:25–48

Goodwin GM (1968) Application of strain analysis to sheet metal forming in the press shop. SAE Trans:380–387

Marciniak Z, Kuczynski K (1967) Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci 9:609–620

Wang H, Wan M, Yan Y (2012) Effect of flow stress−strain relation on forming limit of 5754O aluminum alloy. Trans Nonferrous Met Soc China 22:2370–2378

Wang H, Liu Y, Chen Z, Wan M, Nie H (2016) Investigation of the capabilities of yield functions on describing the deformation behavior of 5754O aluminum alloy sheet under combined loading paths. J Shanghai Jiaotong Univ (Sci.) 21(5):562–568

Pham QT, Lee BH, Park KC, Kim YS (2018) Influence of the post necking prediction of hardening law on the theoretical forming limit curve of aluminum sheets. Int J Mech Sci 140:521–536

Pham QT, Lee MG, Kim YS (2019) Characterization of the isotropic-distortional hardening model and its application to commercially pure titanium sheets. Int J Mech Sci 160:90–102

Graf AF, Hosford WF (1994) The influence of strain path changes on forming limit diagram. Int J Mech Sci 36:897–910

Yoshida K, Kuwabara T, Narihara K, Takahashi S (2005) Experimental verification of the path dependence of forming limit stresses. Int J Form Process 8:283–298

Yoshida K, Kuwabara T, Kuroda M (2007) Path-dependence of the forming limit stresses in a sheet metal. Int J Plast 23:361–384

Zhalehfar F, Hashemi R, Hosseinipour SJ (2015) Experimental and theoretical investigation of strain path change effect on forming limit diagram of AA5083. Int J Adv Man Technol 76(5−8):1343–1352

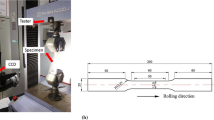

Dhara S, Basak S, Panda SK, Hazra S, Shollock B, Dashwood R (2016) Formability analysis of pre-strained AA5754-O sheet metal using Yld96 plasticity theory: role of amount and direction of uni-axial pre-strain. J Manuf Process 24:270–282

Wang H, Yan Y, Han F, Wan M (2017) Experimental and theoretical investigations of the forming limit of 5754O aluminum alloy sheet under different combined loading paths. Int J Mech Sci 133:147–166

Paul SK (2015) Path independent limiting criteria in sheet metal forming. J Manuf Process 20(1):291–303

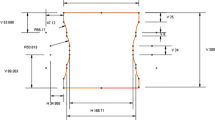

Yuan WN, Wan M, Wu XD, Cheng C, Cai ZY, Ma BL (2018) A numerical MK approach for predicting the forming limits of material AA5754-O. Int J Adv Man Technol 98(1−4):811–825

Ma BL, Wan M, Cai ZY, Li C, Wu XD, Liu W (2018) Investigation on the forming limits of 5754-O aluminum alloy sheet with the M-K approach. Int J Mech Sci 143:420–431

Yuan W, Wan M, Wu X, Ma BL, Lu X, Yang B (2020) Influence of uniaxial tensile pre-strain on forming limit curve by using biaxial tensile test. Chin J Aeronaut 33(8):2268–2280

Banabic D, Soare S (2008) On the effect of the normal pressure upon the forming limit strains. Proceedings Numisheet Conference: 199−204

Assempour A, Nejadkhaki HK, Hashemi R (2010) Forming limit diagrams with the existence of through-thickness normal stress. Comput Mater Sci 48:504–508

Nurcheshmeh M, Green DE (2011) Effects of sheet mechanical properties on forming limits in presence of a through-thickness stress. AIP Conference Proceeding 1353:171–176

Zhang F, Chen J, Chen J, Zhu X (2014) Forming limit model evaluation for anisotropic sheet metals under through-thickness normal stress. Int J Mech Sci 89:40–46

Mirfalah Nasiri SM, Basti A, Hashemi R (2016) Forming limit curves analysis of aluminum alloy considering the through-thickness normal stress anisotropic yield functions and strain rate. Int J Mech Sci 117:93–101

Mirfalah Nasiri SM, Basti A, Hashemi R, Darvizeh A (2018) Effects of normal and through-thickness shear stresses on the forming limit curves of AA3104-H19 using advanced yield criteria. Int J Mech Sci 137:15–23

Erfanian M, Hashemi R (2018) A comparative study of the extended forming limit diagrams considering strain path, through-thickness normal and shear stress. Int J Mech Sci 148:316–326

Ma BL, Wan M, Zhang H, Gong XL, Wu XD (2018) Evaluation of the forming limit curve of medium steel plate based on non-constant through-thickness normal stress. J Manuf Process 33:175–183

Hu Q, Zhang L, Ouyang Q, Li X, Zhu X, Chen J (2018) Prediction of forming limits for anisotropic materials with nonlinear strain paths by an instability approach. Int J Plast 103:143–167

Hu Q, Li X, Chen J (2019) Forming limit evaluation by considering through-thickness normal stress: theory and modeling. Int J Mech Sci 155:187–196

Da Rocha AB, Barlat F, Jalinier JM (1985) Prediction of the forming limit diagrams of anisotropic sheets in linear and non-linear loading. Mater Sci Eng 68:151–164

Zhang F, Chen J, Chen J (2014) Effect of through-thickness normal stress on forming limits under Yld2003 yield criterion and MK model. Int J Mech Sci 89:92–100

Kim YS, Lee BH, Yang SH (2018) Prediction of forming limit curve for pure titanium sheet. Trans. Nonferrous Met Soc China 28:319–327

Barlat F, Brema JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F, Choi SH, Chu E (2003) Plane stress yield function for aluminum alloy sheets. Int J Plast 19:1297–1319

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

Soheila sojodi wrote the manuscript and analyzed the data. Ali Basti supervised the research. Seyed Reza Falahatgar supervised the research and contributed to the final version of manuscript. Seyedeh Maryam Mirfalah Nasiri proposed the idea and contributed to the performance the analysis of data.

Corresponding author

Ethics declarations

Ethical approval

Compliance with ethical standard

Consent to participate

Not applicable

Consent to publish

Not applicable

Competing interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sojodi, S., Basti, A., Falahatgar, S.R. et al. Investigation on the forming limit diagram of AA5754-O alloy by considering strain hardening model, strain path, and through-thickness normal stress. Int J Adv Manuf Technol 113, 2495–2511 (2021). https://doi.org/10.1007/s00170-021-06801-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06801-4