Abstract

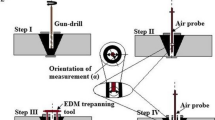

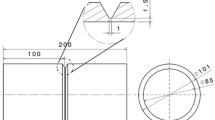

The stainless clad steel materials (particularly A283-Gr-C hot-rolled to austenitic stainless steel plate SA240 TP 316L) have become widely used in the fabrication of heat exchangers, pressure vessels, and other components owing to their very interesting properties and low production cost. These cladded materials are mostly joined using multi-pass welding techniques. The temperature distribution that supervenes during welding affects the microstructures and the mechanical properties and may generate residual stresses in the heat-affected zone of the welded plates. Since limited experimental data are available in the literature regarding the complex cases of multi-pass welding of cladded steel materials, a thorough experimental study was performed in order to evaluate the temperature distribution on the welded plates. In fact, eight K-type thermocouples were fixed at different distances from the weld centerline in order to record the temperature evolution along longitudinal, transversal, and thickness directions during the welding process. Due to the unavoidable effects of the generated heat fluxes that always follow the welding, several dimensional changes were occurred on the welded plates. In this study, the longitudinal shrinkage and the angular distortion generated during the welding process by the effect of the heat fluxes were investigated. Then, tensile and bending tests were performed in order to check the welded plate reliability. It was found that (i) the welded joint presents a higher mechanical tensile strength than the parent metal and (ii) no separations, fractures, or tearing appear on the weld joint surface after the bending test.

Similar content being viewed by others

References

Kaya Y, Kahraman N (2013) An investigation into the explosive welding/cladding of Grade A ship steel/AISI 316L austenitic stainless steel. Mater Des (1980-2015):52, 367372. https://doi.org/10.1016/j.matdes.2013.05.033

Venkateswara Rao N, Madhusudhan Reddy G, Nagarjuna S (2011) Weld overlay cladding of high strength low alloy steel with austenitic stainless steel – structure and properties. Mater Des 32(4):2496–2506. https://doi.org/10.1016/j.matdes.2010.10.026

Khodadad Motarjemi A, Koçak M, Ventzke V (2002) Mechanical and fracture characterization of a bi-material steel plate. Int J Press Vessel Pip 79(3):181–191. https://doi.org/10.1016/S0308-0161(02)00012-1

Ganesh P, Moitra A, Tiwari P, Sathyanarayanan S, Kumar H, Rai SK et al (2010) Fracture behavior of laser-clad joint of Stellite 21 on AISI 316L stainless steel. Mater Sci Eng A 527(16-17):37483756. https://doi.org/10.1016/j.msea.2010.03.017

Flahaut P (1995) Caractérisation et comportement mécanique de placages bimétalliques. Doctoral dissertation, Lille 1. https://ori-nuxeo.univ-lille1.fr/nuxeo/site/esupversions/edaf9d60-01c6-4814-b6c0-7902697c9fc0

Akramifard HR, Mirzadeh H, Parsa MH (2014) Cladding of aluminum on AISI 304L stainless steel by cold roll bonding: mechanism, microstructure, and mechanical properties. Mater Sci Eng A 613:232–239. https://doi.org/10.1016/j.msea.2014.06.109

Azzeddine H, Tirsatine K, Baudin T, Helbert A-L, Brisset F, Bradai D (2014) Texture evolution of an Fe–Ni alloy sheet produced by cross accumulative roll bonding. Mater Charact 97:140–149. https://doi.org/10.1016/j.matchar.2014.09.009

Jing Y, Qin Y, Zang X, Li Y (2014) The bonding properties and interfacial morphologies of clad plate prepared by multiple passes hot rolling in a protective atmosphere. J Mater Process Technol 214(8):1686–1695. https://doi.org/10.1016/j.jmatprotec.2014.03.019

Dhib Z, Guermazi N, Gaspérini M, Haddar N (2016) Cladding of low-carbon steel to austenitic stainless steel by hot-roll bonding: microstructure and mechanical properties before and after welding. Mater Sci Eng A 656:130–141. https://doi.org/10.1016/j.msea.2015.12.088

Qin G, Tang Y, Zhang B, Lin S, Geng P (2020) Microstructures and mechanical properties of stainless steel clad plate joint with diverse filler metals. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2019.12.083

An Q, Fan KY, Ge YF, Liu BX, Liu YC, Wang S et al (2020) Microstructure and mechanical properties of stainless steel clad plate joints produced by TIG and MAG hybrid welding. J Adhes Sci Technol 34(6):670–685. https://doi.org/10.1080/01694243.2019.1677087

Qiu T, Wu BX, Chen QY, Chen WJ (2013) Analysis on welded joint properties of stainless clad steel plates. Dianhanji/ Electric Welding Machine 43(4):83–87

Missori S, Murdolo F, Sili A (2004) Single-pass laser beam welding of clad steel plate. Weld J https://art.torvergata.it/retrieve/handle/2108/60687/101757/WJ-02-2004-MISSORI-s.pdf

Moore JP (1954) Maintaining the corrosion resistance of welded stainless steel. Anti-Corros Methods Mater 1(4):92–112. https://doi.org/10.1108/eb018925

Jiang W, Liu Z, Gong JM, Tu ST (2010) Numerical simulation to study the effect of repair width on residual stresses of a stainless steel clad plate. Int J Press Vessel Pip 87(8):457–463. https://doi.org/10.1016/j.ijpvp.2010.06.003

Hajiannia I, Shamanian M, Kasiri M (2013) Microstructure and mechanical properties of AISI 347 stainless steel/A335 low alloy steel dissimilar joint produced by gas tungsten arc welding. Mater Des 50:566–573. https://doi.org/10.1016/j.matdes.2013.03.029

Wang SG, Dong GP, Ma QH (2009) Welding of duplex stainless steel composite plate: influence on microstructural development. Mater Manuf Process 24(12):1383–1388. https://doi.org/10.1080/10426910902997456

Park J-W, Lee C-K (2013) Mechanical properties and sensitization on clad steel welding design. Int J Precis Eng Manuf 14(11):1939–1945. https://doi.org/10.1007/s12541-013-0263-z

Itsuro T, Isamu O, Isamu T, Izumi O Welding distortion of austenitic stainless clad steel. J Jpn Weld Soc. https://doi.org/10.2207/qjjws1943.43.684

ASME IX (2017) ASME boiler and pressure vessel code, section IX: welding and brazing qualifications. An International Code, New York

Kumar KVS, Gejendhiran S, Prasath M (2014) Comparative investigation of mechanical properties in GMAW/GTAW for various shielding gas compositions. Mater Manuf Process 29(8):996–1003. https://doi.org/10.1080/10426914.2014.901527

Ferjutz K, Joseph R D (1993) ASM Handbook Welding, Brazing and Soldering, vol. 6. ASM International, Materials Park

ANSI/AWS B2.1-1-016-94R (1993) Standard welding procedure specification (WPS) for shielded metal arc welding of carbon steel (M-1/P-1/S-1, group 1 or 2) 1/8 through 1 1/2 inch thick, E7018 As-Welded or PWHT condition, p25

ANSI/AWS B2.1-8-024 (2001) Standard welding procedure specification (WPS) for Gas Tungsten Arc Welding of Austenitic Stainless steel (M-8/P-8/S-8, group 1) 1/16 through 1 1/2 inch thick, ER3XX As-Welded Condition. Primarily Plate and Structural Applications, USA

Lee Y, Bandari Y, Nandwana P, Gibson B, Richardson B, Simunovic S (2019) Effect of interlayer cooling time, constraint and tool path strategy on deformation of large components made by laser metal deposition with wire. Appl Sci 9(23):5115. https://doi.org/10.3390/app9235115

Bandari YK, Lee Y, Nandwana P, Richardson BS, Adediran AI, Love LJ, Gaul KT (2018) Effect of inter-layer cooling time on distortion and mechanical properties in metal additive manufacturing (AM). Oak Ridge National Lab.(ORNL), Oak Ridge https://www.osti.gov/servlets/purl/1474452

Fessler JR, Merz R, Nickel AH, Prinz FB, Weiss LE (1996) Laser deposition of metals for shape deposition manufacturing. In 1996 International Solid Freeform Fabrication Symposium. https://repositories.lib.utexas.edu/bitstream/handle/2152/69928/1996-15-Fessler.pdf?sequence=2&isAllowed=y

American Petroleum Institute Recommended Practice, API RP 582 (2016) “Welding Guidelines for the Chemical, Oil, and Gas Industries”

ASME section VIII, Division 1 (2017) ASME Boiler and Pressure Vessel Code, Rules for Construction of Pressure Vessels

ASTM Committee E-20 on Temperature Measurement, & ASTM Committee E-20 on Temperature Measurement. Subcommittee E20. 04 on Thermocouples (1974) Manual on the use of thermocouples in temperature measurement (Vol. 470). ASTM International

Murugan S, Kumar P, Raj B, Bose MS (1998) Temperature distribution during multipass welding of plates. Int J Press Vessel Pip 75(12):891–905. https://doi.org/10.1016/S0308-0161(98)00094-5

ASM International (1990) ASM Handbook. Properties and selection: irons steels and high performance alloys. Vol.01, 10th Edition, p.1063, 3rd Edition, USA

Murugan VV, Gunaraj V (2005) Effects of process parameters on angular distortion of gas metal arc welded structural steel plates. Weld J 11:165–171 https://app.aws.org/wj/supplement/WJ_2005_11_s165.pdf

de Oliveira Silva M, de Araújo DB, Souza D, de Freitas Teixeira PR (2015) The effect of the number of welding passes in the angular distortion of 304l steel plates using gmaw. https://doi.org/10.20906/CPS/COB-2015-1123

Seyyedian Choobi M, Haghpanahi M, Sedighi M (2011) Effect of welding sequence and direction on angular distortions in butt-welded plates. J Strain Anal Eng Des 47(1):46–54. https://doi.org/10.1177/0309324711425887

Chiumenti M, Cervera M, Salmi A, Agelet de Saracibar C, Dialami N, Matsui K (2010) Finite element modeling of multi-pass welding and shaped metal deposition processes. Comput Methods Appl Mech Eng 199(37-40):2343–2359. https://doi.org/10.1016/j.cma.2010.02.018

Manurung YHP, Lidam RN, Rahim MR, Zakaria MY, Redza MR, Sulaiman MS et al (2013) Welding distortion analysis of multipass joint combination with different sequences using 3D FEM and experiment. Int J Press Vessel Pip 111-112:89–98. https://doi.org/10.1016/j.ijpvp.2013.05.002

Li C, Qin G, Tang Y, Zhang B, Lin S, Geng P (2020) Microstructures and mechanical properties of stainless steel clad plate joint with diverse filler metals. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2019.12.083

Acknowledgments

The authors would like to thank SOCOMENIN Company for their support. They equally would like to thank Mr. M.T. Hbaieb and A. Badri, staff engineers at SOCOMENIN Company, for their knowledgeable help and support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate not applicable

Not applicable

Conflict of interest

The authors declare that they have no conflict of interest

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghorbel, R., Ktari, A. & Haddar, N. Experimental analysis of temperature field and distortions in multi-pass welding of stainless cladded steel. Int J Adv Manuf Technol 113, 3525–3542 (2021). https://doi.org/10.1007/s00170-021-06788-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06788-y