Abstract

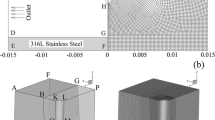

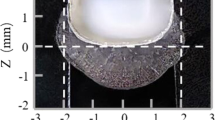

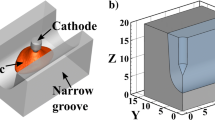

Obtaining uniform penetration on welding groove faces is one urgent problem in oscillation arc narrow gap welding; however, the heat flux distribution on the groove face under the deflected welding arc is difficult to investigate by the experimental method. In this article, a unified three-dimensional model is developed to study the heat flux distribution on groove faces. The model includes the electrode, welding arc, workpiece, and their coupling. The plasma arc profile, heat flux characteristics, and weld pool formation were simulated. Based on the simulation results, the following conclusions were contained. The deflecting degree of the welding arc axis is increased with the increasing of extra magnetic-field intensity, and this leads to the change of the distribution of conduction heat flux and electric heat flux. At the groove bottom, both heat fluxes move to one side, and their distribution shape changes from circular to elliptical. At the sidewall, the distribution shape of conduction heat flux is triangular, and that of electrical heat flux is elliptical. The maximum value of heat flux density decreased, and the affected area was increased with the associate of the extra magnetic field. The simulation welding bead was in agreement with the experimental result.

Similar content being viewed by others

References

Xu W, Lin S, Fan C, Yang C (2015) Prediction and optimization of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int J Adv Manuf Technol 79(1-4):183–196

Zhu C, Tang XH, He Y, Lu F, Cui H (2018) Effect of preheating on the defects and microstructure in NG-GMA welding of 5083 Al-alloy. J Mater Process Technol 251:214–224

Cai X, Dong B, Lin S, Murphy AB, Fan C, Yang C (2019) Heat Source Characteristics of Ternary-Gas-Shielded Tandem Narrow-Gap GMAW. Materials. 12(9):1397

Guo N, Wang MR, Guo W, Yu JB, Feng JC (2014) Effect of rotating arc process on molten pool control in horizontal welding. Sci Technol Weld Join 19(5):385–391

Wang J, Zhu J, Zhang C, Xu G, Li W (2016) Effect of Arc Swing Parameters on Narrow Gap Vertical GMA Weld Formation. ISIJ Int 56:844–850

Belous VY, Akhonin SV (2007) Influence of controlling magnetic field parameters on weld formation in narrow gap argon-arc welding of titanium alloys. Paton Weld J 4:2–5

Sun QJ, Hun HF, Li WJ, Liang YC, Feng JC (2013) Electrode tips geometry and penetrating in narrow gap welding. Sci Technol Weld Join 18:198–203

Belous VY (2011) Conditions for formation of defect-free welds in narrow-gap magnetically controlled arc welding of low titanium alloys. Paton Weld J 3:16–18

Wang J, Sun Q, Zhang T, Zhang S, Liu Y, Feng J (2018) Arc characteristics in alternating magnetic field assisted narrow gap pulsed GTAW. J Mater Process Technol 254:254–264

Sun QJ, Wang J, Cai C, Li Q, Feng J (2016) Optimization of magnetic arc oscillation system by using double magnetic pole to TIG narrow gap welding. J Adv Manuf Technol 86(1):761–767

Wang J, Sun Q, Feng J, Wang S, Zhao H (2017) Characteristics of welding and arc pressure in TIG narrow gap welding using novel magnetic arc oscillation. Int J Adv Manuf Technol 90:413–420

Kang YH, Na SJ (2003) Characteristics of welding and arc signal in narrow groove gas metal arc welding using electromagnetic arc oscillation. Weld J 82(5):93/S–99/S

Xu G, Wang J, Li P, Zhu J, Cao Q (2017) Numerical analysis of heat transfer and fluid flow in swing arc narrow gap GMA welding. J Mater Process Technol 252:260–269

Häßler M, Rose S, Füssel U, Schneider HI, Werner C (2015) TIG narrow gap welding-new approaches to evaluate and improve the shielding gas coverage and the energy input. Weld World 59(1):71–76

Zhu C, Tang X, He Y, Lu F, Cui H (2017) Study on arc characteristics and their influences on weld bead geometry in narrow gap GMAW of 5083 Al-alloy. Int J Adv Manuf Technol 90:2513–2525

Xu WH, Lin SB, Fan CL, Zhuo XQ, Yang CL (2014) Statistical modeling of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int J Adv Manuf Technol 72:1705–1716

Murphy AB (2011) A self-consistent three-dimensional model of the arc, electrode and weld pool in gas–metal arc welding. J Phys D Appl Phys 44:194009

Yin X, Gou J, Zhang J, Sun J (2012) Numerical study of arc plasmas and weld pools for GTAW with applied axial magnetic fields. J Phys D Appl Phys 45:285203

Tanaka Y, Fujino T, Iwao T (2019) Review of thermal plasma simulation technique. IEEJ Trans Electr Electron Eng 14:1582–1594

Lowke JJ, Tanaka M (2006) ‘LTE-diffusion approximation’for arc calculation. J Phys D Appl Phys 39:3634–3643

Murphy AB, Arundell CJ (1994) Transport coefficients of argon, nitrogen, oxygen, argon-nitrogen, and argon-oxygen plasmas. Plasma Chem Plasma Process 14(4):451–490

Cram LE (1985) Statistical evaluation of radiative power losses from thermal plasmas due to spectral lines. J Phys D Appl Phys 18(3):401–411

Tao Z, Wu CS, Feng Y (2011) Numerical analysis of heat transfer and fluid flow in keyhole plasma arc welding. Numer Heat Tr A-Appl 60(8):685–698

Funding

This study was supported by the National Natural Science Foundation of China (grant no. 51705133) and the Open Research Fund Program of Hubei Provincial Key Laboratory of Chemical Equipment Intensification and Intrinsic Safety (grant no. 2019KA02), and Wuhan Institute of Technology Science Foundation (grant no. K202009).

Author information

Authors and Affiliations

Contributions

The corresponding author X.J. was responsible for writing this paper, planning, simulation, and experiment. H.W. was responsible for supervising the mechanical analysis.

Corresponding author

Ethics declarations

Consent to publish

All the authors have reached agreement for publication.

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiaoxia, J., Hebao, W. Numerical investigation of heat flux distribution on the welding groove face in magnetic oscillation arc narrow gap GTAW. Int J Adv Manuf Technol 113, 2315–2325 (2021). https://doi.org/10.1007/s00170-021-06735-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06735-x