Abstract

In diamond turning of polymer bonded explosives (PBXs), a transient temperature monitoring tool is crucial for the processing safety issues. Three design principles are proposed in this work to fulfill the accurate prediction of the temperature distribution on tool cutting edge by using gradient calibration method and heat transfer simulation. Subsequently, the detailed design, microfabrication, and self-calibration test are successfully performed to establish the temperature measuring tool based on a natural diamond cutting tool. A theoretical model is further established to predict the transient temperature of the tool tip in the limit turning experiment and explore the safe cutting factors of typical PBXs. The results show that (1) the unsteady heat transfer model can better describe the self-calibration process of the tool, and it can accurately predict the transient temperature on the tool tip using the error distribution law; (2) finite element method can not only obtain the global temperature distribution field but also analyze the influences of tool structure, material selection, and thermal boundary conditions on prediction errors; and (3) cutting speed, tool tip wear, dry cutting are the key factors that affect the cutting safety of PBXs, and the maximum safe cutting speed vmax ≈ 33.5 m/s.

Similar content being viewed by others

Data availability

All data is published with the paper.

References

Skidmore CB, Fleming KA (2017) The essential role of science in explosives safety. 26th ICDERS (Science in Safety), Boston, MA, USA, pp 1–6

Keyhani A, Horie Y, Zhou M (2017) Relative importance of plasticity and fracture/friction in ignition of polymer-bonded explosives (PBXs). 20th Biennial Conference of APS Topcial Group on Shock Compression of Condensed Matter Meeting, pp Z4–001

Akiki M, Gallagher TP, Menon S (2016) Mechanistic approach for simulating hot-spot formations and detonation in polymer-bonded explosives. AIAA J 55(2):585–598

Soler D, Aristimuño PX, Saez-de-Buruaga M, Garay A, Arrazola PJ (2018) New calibration method to measure rake face temperature of the tool during dry orthogonal cutting using thermography. Appl Therm Eng 137:74–82

Sugita N, Ishii K, Furusho T, Harada K, Mitsuishi M (2015) Cutting temperature measurement by a micro-sensor array integrated on the rake face of a cutting tool. CIRP Ann 64(1):77–80

Woodrum RB (2017) Developing lathing parameters for PBX 9501. Dissertation, Texas Tech University.

Woodrum RB, Barnett DH, Dickens JC, Neuber AA (2018) Developing safe lathing parameters for PBX 9501. Propellants Explos Pyrotech 43(8):779–788

Liu R, Chen PW (2018) Modeling ignition prediction of HMX-based polymer bonded explosives under low velocity impact. Mech Mater 124:106–117

Akbari M, Kliuev M, Boos J, Wegener K (2018) Flash temperature and force measurements in single diamond scratch tests. Int J Adv Manuf Technol 96(9-12):4393–4405

Li J, Tao B, Huang S, Yin Z (2019) Cutting tools embedded with thin film thermocouples vertically to the rake face for temperature measurement. Sensors Actuators A Phys 296:392–399

Biermann D, Kirschner M, Pantke K, Tillmann W (2013) New coating systems for temperature monitoring in turning processes. Surf Coat Technol 215:376–380

Kesriklioglu S, Morrow JD, Pfefferkorn FE (2018) Tool–chip interface temperature measurement in interrupted and continuous oblique cutting. J Manuf Sci Eng 140(5):051013

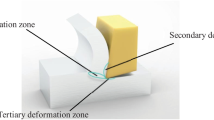

Huang J, Lu S, Xie F, Liu W, Sun T (2020) Finite element analysis of synergetic deformation in precision cutting of polymer bonded explosive. Mater Des 188:108471

Cao Z, Zong W, Zhang J, Xiao C, He C (2020) Desensitising effect of water film on initial decomposition of HMX crystal under nano-cutting conditions by ReaxFF MD simulations. Mol Simul 46(7):1–11

Jackson MJ, Nelson JK, Whitfield MD, Morrell JS, Schmidt PL (2018) Chip formation and similarity in the plano-grinding of explosive surrogates. Proc Inst Mech Eng B J Eng Manuf 232(12):2071–2082

Sutter G, Faure L, Molinari A, Ranc N, Pina V (2003) An experimental technique for the measurement of temperature fields for the orthogonal cutting in high speed machining. Int J Mach Tools Manuf 43(7):671–678

Tillmann W, Vogli E, Herper J, Biermann D, Pantke K (2010) Development of temperature sensor thin films to monitor turning processes. J Mater Process Technol 210(5):819–823

Ning J, Liang S (2018) Prediction of temperature distribution in orthogonal machining based on the mechanics of the cutting process using a constitutive model. J Manuf Mater Process 2(2):37

Yan Q, Zeman S, Elbeih A (2012) Recent advances in thermal analysis and stability evaluation of insensitive plastic bonded explosives (PBXs). Thermochim Acta 537:1–12

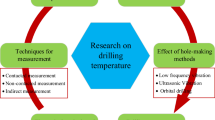

Clark R, Neuber AA, Lee RJ, Hewitt AT, Mankowski JJ (2019) Ignition mechanisms of polymer bonded explosives during drilling. IEEE Pulsed Power Plasma Sci. https://doi.org/10.1109/PPPS34859.2019.9009974

Yue D, Ji T, Qin T, Wang J, Liu C, Jiao H, Zhao L, Han Y, Gao C (2018) Accurate temperature measurement by temperature field analysis in diamond anvil cell for thermal transport study of matter under high pressures. Appl Phys Lett 112(8):081901

Zong WJ, Cao ZM, He CL, Sun T (2015) Critical undeformed chip thickness of brittle materials in single point diamond turning. Int J Adv Manuf Technol 81(5-8):975–984

Wu B, Zong WJ, Niu CY (2019) An in situ method to evaluate the waviness of rounded cutting edge of diamond tool. Int J Adv Manuf Tech 106(5–6):1–11

Cui Y, Liu Q, Wang L, Ding W, Li D (2018) Research on milling temperature measuring tool embedded with NiCr/NiSi thin film thermocouple. Procedia CIRP CMS 72:1457–1462

Li J, Tao B, Huang S, Yin Z (2018) Built-in thin film thermocouples in surface textures of cemented carbide tools for cutting temperature measurement. Sensors Actuators A Phys 279:663–670

Borzenko EI, Shrager GR (2015) Effect of the type of boundary conditions on the three-phase contact line on the flow characteristics during filling of the channel. J Appl Mech Tech Phys 56(2):167–176

Patankar SV (2017) Computation of conduction and duct flow heat transfer. Crc Press Inc, Routledge, pp 154–182

Yu SJ, Wang DD, Chen X (2015) Numerical simulation of metal cutting process based on ANSYS/LS-DYNA. Appl Mech Mater 727-728:335–338. https://doi.org/10.4028/www.scientific.net/AMM.727-728.335

Zhao Y, Sun J, Li J, Yan Y, Wang P (2017) A comparative study on Johnson-Cook and modified Johnson-Cook constitutive material model to predict the dynamic behavior laser additive manufacturing FeCr alloy. J Alloys Compd 723:179–187

Roman RE, Kwan K, Cranford SW (2015) Mechanical properties and defect sensitivity of diamond nanothreads. Nano Lett 15(3):1585–1590

Jensen BD, Wise KE, Odegard GM (2015) Simulation of the elastic and ultimate tensile properties of diamond, graphene, carbon nanotubes, and amorphous carbon using a revised ReaxFF parametrization. J Phys Chem A 119(37):9710–9721

Ning J, Liang SY (2019) Inverse identification of Johnson-Cook material constants based on modified chip formation model and iterative gradient search using temperature and force measurements. Int J Adv Manuf Technol 102(9-12):2865–2876

He SW, Xiao CH, Li F (2018) Application of maximum entropy test method in safety management of explosive machine processing. Safety 1:30–32 (In Chinese)

DOE-STD-1212-2012, Doe Standard Explosives Safety (2012) Department of Energy, Washington, DC 20585, pp 64–70. https://engergy.gov/ehss/downloads/doe-std-1212-2012

Funding

This work was supported by the National Natural Science Foundation of China (No. 51675133) and the Science Challenge Project (No. TZ2018006-0202-02).

Author information

Authors and Affiliations

Contributions

Zhimin Cao: conceptualization, methodology, investigation, writing–original draft. Wenjun Zong: conceptualization, funding acquisition, writing–review and editing. Chunlei He: software, validation, visualization. Jiaohu Huang: supervision, investigation, data curation. Wei Liu: software, resources, data curation. Zhiyong Wei: conceptualization, resources, supervision.

Corresponding author

Ethics declarations

Ethical approval

This work does not contain any ethical issues or personal information.

Consent to participate

No human or animal was involved in this work; thus, no consent was required.

Consent for publication

All authors have given their permission for publishing this work.

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cao, Z., Zong, W., He, C. et al. Transient temperature monitoring and safe cutting speed exploration in diamond turning of PBX surrogates. Int J Adv Manuf Technol 113, 3433–3443 (2021). https://doi.org/10.1007/s00170-021-06731-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06731-1