Abstract

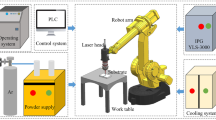

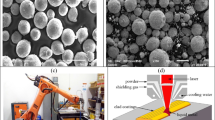

Taguchi design of experiments (DoE) was employed to determine appropriate laser cladding (LC) parameters for optimising microstructural and anti-wear properties of Tribaloy (T-800) coatings. The nature of wear mechanism was also explored with scanning electron microscopy (SEM). Statistical analysis established that both microhardness and wear rates were primarily dependent on powder feed rates and scanning speeds while coefficient of friction (COF) is significantly influenced by spot diameter. Variation in wear morphology, across the samples, could be explained by presence or absence of surface defects; sizes of surface defects, distance between the surface defects as well as the nature of evolving microstructure within the clad samples. Optimum samples were imparted with microhardness (900 HV), COF (0.0743) and specific wear rate (0.0071 mm3/N/m), and these compared favourably well with the predicted values. Samples fabricated with optimum LC parameters are suitable for wear application in mining industries.

Similar content being viewed by others

References

Lin Y, Gaebler JP, Tan TR, Bowler R, Jost JD, Leibfried D, Wineland DJ (2013) Sympathetic electromagnetically-induced-transparency laser cooling of motional modes in an ion chain. Phys Rev Lett 110:153002. https://doi.org/10.1103/PhysRevLett.110.153002

Che L, Sun W, Huang Y, Chao Y (2014) Laser cladding technology in the repair of shearer picks. Comput Model NEW Technol 18:563–565

Wu H, Cheng Y-Y (2017) Effect of two-body and three-body microcontacts under dry friction on contact characteristics. J Mech Eng Sci 232:706–719

Malikongwa K (2019) Manufacturing of wear resistant clads for tailings/slurry pump impeller via laser cladding (LC) technology, Masters thesis, Department of Mechanical, Energy and Industrial eng., Faculty of Engineering, Botswana University of Science and Technology, p 179. https://repository.biust.ac.bw/handle/123456789/111

Sarkar M, Mukherjee PS, Ghosh SK (2013) Experimental and mathematical analysis of wear generation at bottom plate of mine excavator bucket. Proc Inst Mech Eng J: J Eng Tribol 230(12):1483–1489. https://doi.org/10.1177/1350650116640152

Suryo SH, Bayuseno AP, Jamari J, Ramadhan MAR (2018) Analysis of AISI material power of AISI 4140 bucket teeth excavator using influence of abrasive wear. AIP Conf Proc. https://doi.org/10.1063/1.5042942

Jamal A, Kumar R, Singh RP, Singh NP, Digarse AK (2016) Determination Of longevity of teeth in buckets of loading equipment in coal mines -a case study. Int J Sci Technol Res 5(2):25–35. https://www.ijstr.org/finalprint/feb2016/Determination-Of-Longevity-Of-Teeth-In-Buckets-Of-Loading-Equipment-In-Coal-Mines-A-Case-Study.pdf. Accessed 16 Oct 2019

Hoseinie SH, Ataei M, Mikaiel R (2012) Comparison of some rock hardness scales applied in Drillability Studies. Arab J Sci Eng 37:1451–1458. https://doi.org/10.1007/s13369-012-0247-9

Altun AA, Prochaska T, Konegger T, Schwentenwein M (2020) Dense, strong, and precise silicon nitride-based ceramic parts by Lithography-based ceramic manufacturing. Appl Sci 10(3):996. https://doi.org/10.3390/app10030996

Bunin IZ h, Anashkina NE, Ryazantseva MV (2018) Application of repetitive high power (high voltage) nanosecond electromagnetic pulses to improve technological properties of diamond-bearing kimberlites. J Phys Conf Ser 1115:052015. https://doi.org/10.1088/1742-6596/1115/5/052015

Gedda H (2004) Laser cladding: an experimental and theoretical investigation. PhD Thesis, Lulea University of Technology, Sweden, pp.38. https://www.diva-portal.org/smash/get/diva2:989990/FULLTEXT01.pdf

Wang D, Hu Q, Zeng X (2015) Residual stress and cracking behaviors of Cr13Ni5Si2 based composite coatings prepared by laser-induction hybrid cladding. Surf Coat Technol 274:51–59. https://doi.org/10.1016/j.surfcoat.2015.04.035

Gu D, Wang H, Dai D, Chang F, Meiners W, Hagedorn Y-C, Wissenbach K, Kelbassa I, Poprawe R (2015) Densification behavior, microstructure evolution, and wear property of TiC nanoparticle reinforced AlSi10Mg bulk-form nanocomposites prepared by selective laser melting. J Laser Appl 27:S17003. https://doi.org/10.2351/1.4870877

Gu D (2015) Laser additive manufacturing of high-performance materials. Laser Addit Manuf High Perform Mater:1–311. https://doi.org/10.1007/978-3-662-46089-4

Ruan Y, Chang SY, Dao M (2015) Comparative effect of rapid dendrite growth and element addition on microhardness enhancement of Fe-based alloys. Cryst Growth Des 15:5661–5664. https://doi.org/10.1021/acs.cgd.5b01167

Bayer RG (2004) Mechanical wear fundamentals and testing, 2nd edn. Taylor & Francis Inc, New York. https://doi.org/10.1201/9780203021798.fmatt

Navas C, Colaço R, De Damborenea J, Vilar R (2006) Abrasive wear behaviour of laser clad and flame sprayed-melted NiCrBSi coatings. 200:6854–6862. https://doi.org/10.1016/j.surfcoat.2005.10.032

Rajesh S, Rajakarunakaran S, Pandian RS (2012) Modeling and optimization of sliding specific wear and coefficient of friction of aluminum based red mud metal matrix composite using taguchi method and response surface methodology. 15:150–166. http://www.ipme.nw.ru/ejournals/MPM/no_21512/MPM215_07_rajesh.pdf

Barekat M, Shoja R, Ghasemi A (2016) Optics & laser technology Nd : YAG laser cladding of Co – Cr – Mo alloy on γ -TiAl substrate. Opt Laser Technol 80:145–152. https://doi.org/10.1016/j.optlastec.2016.01.003

Bajwa R, Khan Z, Nazir H, Chacko V, Saeed A (2016) Wear and friction properties of electrodeposited Ni-based coatings subject to nano-enhanced lubricant and composite coating. Acta Metall Sin (English Lett) 29:902–910. https://doi.org/10.1007/s40195-016-0470-6

Shebani A, Pislaru C (2015) Wear measuring and wear modelling based on Archard , ASTM , and Neural Network Models. Int J Mech Aerosp Ind Mechatron Eng 9:177–182

Funding

This research is supported by the African Laser Center (ALC) under Grant no. CSIR-NLC Reference LHIL 500 task ALC R014 and Botswana International University of Science & Technology (BIUST) Research Initiation Fund under Grant no. BIUST/ds/r&I/7/2016. The authors are grateful to Mr. Samuel Skhosane for his assistance in operating the laser facility at CSIR, Pretoria, South Africa.

Author information

Authors and Affiliations

Contributions

Conceptualization: EOO and KM, investigation; KM and MT, methodology, KM, MT and EOO, resources; EOO and MT, supervision; EOO and MT, writing of original draft; KM, writing of review and editing; EOO and MT, funding acquisition. All authors have read and agreed to the published version of the manuscript

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Malikongwa, K., Tlotleng, M. & Olakanmi, E.O. Optimisation of the wear resistance properties of laser cladded T-800 coatings. Int J Adv Manuf Technol 114, 481–496 (2021). https://doi.org/10.1007/s00170-021-06718-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06718-y