Abstract

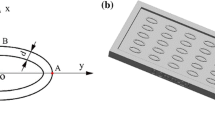

Hot embossing is a technique used to fabricate high-precision and high-quality polymeric components that combines low costs with high aspect ratio fidelity replication. In this study, we manufactured two aspherical Fresnel molds employing the single-point diamond turning process on an electrolytic copper workpiece, one with 10 μm constant height 30 zones and the other with 250 μm constant width 40 zones. The micromachined mold reproduced PMMA convex-plane lens optical quality replicas through the micro hot embossing technique. We used a scanning electron microscope (SEM), spectrophotometry, and non-contact optical profilometer to evaluate the replication fidelity qualitatively: the lens mold and the fine three-dimensional microstructures on the PMMA substrate surfaces. The results of the surface finish of the diamond machined mold sample are in the range of 4.92 nm (areal average surface roughness Sa) and 6.04 nm (areal root-mean-squared roughness Sq), respectively, and the values for the replicas being 4.73 nm and 5.94 nm, respectively. The results demonstrated that the geometry form accuracy obtained of the microfeatures was at the submicron level with little viscoelastic recovery. The surface roughness in the nanometer level got successfully replicated.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and analyzed during the current study are available from the corresponding author on reasonable request.

References

Joo JY, Lee SK (2009) Miniaturized TIR fresnel lens for miniature optical LED applications. Int J Precis Eng Manuf 10:137–140. https://doi.org/10.1007/s12541-009-0038-8

Krizmanic J, Morgan B, Streitmatter R, Gehrels N, Gendreau K, Arzoumanian Z, Ghodssi R, Skinner G (2005) Development of ground-testable phase fresnel lenses in silicon. Exp Astron 20:299–306. https://doi.org/10.1007/s10686-006-9030-9

Zhang X, Huang R, Liu K, Kumar AS, Shan X (2018) Rotating-tool diamond turning of Fresnel lenses on a roller mold for manufacturing of functional optical film. Precis Eng 51:445–457. https://doi.org/10.1016/j.precisioneng.2017.09.016

Huang R, Zhang X, Kumar AS, Liu K, Rahman M (2017) Profile evaluation of radial Fresnel lens directly machined on roller molds by rotating-tool diamond turning. Precis Eng 50:44–52. https://doi.org/10.1016/j.precisioneng.2017.04.012

Peng L, Deng Y, Yi P, Lai X (2014) Micro hot embossing of thermoplastic polymers: a review. J Micromech Microeng 24:013001. https://doi.org/10.1088/0960-1317/24/1/013001

Lin TH, Isayev AI, Mehranpour M (2008) Luminance of injection-molded V-groove light guide plates. Polym Eng Sci 48:1615–1623. https://doi.org/10.1002/pen.21138

Roeder M, Guenther T, Zimmermann A (2019) Review on fabrication technologies for optical mold inserts. Micromachines 10. https://doi.org/10.3390/mi10040233

Wang J, Yi P, Deng Y, Peng L, Lai X, Ni J (2017) Recovery behavior of thermoplastic polymers in micro hot embossing process. J Mater Process Technol 243:205–216. https://doi.org/10.1016/j.jmatprotec.2016.12.024

Shan XC, Maeda R, Murakoshi Y (2003) Micro hot embossing for replication of microstructures. Jpn J Appl Phys Part 1 Regul Pap Short Notes Rev Pap 42:3859–3862. https://doi.org/10.1143/jjap.42.3859

Smith WJ (2000) Modern optical engineering, 4th edn. Spie. https://doi.org/10.1036/0071476873

Spina R, Walach P, Schild J, Hopmann C (2012) Analysis of lens manufacturing with injection molding. Int J Precis Eng Manuf 13:2087–2095. https://doi.org/10.1007/s12541-012-0276-z

Liu C, Li JM, Liu JS, Wang LD (2010) Deformation behavior of solid polymer during hot embossing process. Microelectron Eng 87:200–207. https://doi.org/10.1016/j.mee.2009.07.014

Gao Y, Jin P, Liu J, Liu T, Prewett PD, Tan J (2012) Control of polymer recovery during replication of micro-optical elements with continuous relief in fused silica. Microelectron Eng 91:106–111. https://doi.org/10.1016/j.mee.2011.10.008

Yan J, Maekawa K, Tamaki J, Kuriyagawa T (2005) Micro grooving on single-crystal germanium for infrared Fresnel lenses. J Micromech Microeng 15:1925–1931. https://doi.org/10.1088/0960-1317/15/10/019

Brinksmeier E, Karpuschewski B, Yan J, Schönemann L (2020) Manufacturing of multiscale structured surfaces. CIRP Ann 69:717–739. https://doi.org/10.1016/j.cirp.2020.06.001

Leung HM, Zhou G, Yu H, Chau FS, Kumar AS (2010) Diamond turning and soft lithography processes for liquid tunable lenses. J Micromech Microeng 20:025021. https://doi.org/10.1088/0960-1317/20/2/025021

Bäumer S (2010) Handbook of plastic optics, 2nd edn. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. https://doi.org/10.1002/9783527635443

Zhang HL, Ong NS, Lam YC (2007) Effects of surface roughness on microinjection molding. Polym Eng Sci 47:2012–2019. https://doi.org/10.1002/pen.20904

Der Chien R (2006) Hot embossing of microfluidic platform. Int Commun Heat Mass Transfer 33:645–653. https://doi.org/10.1016/j.icheatmasstransfer.2006.01.017

Deshmukh SS, Goswami A (2019) Hot embossing of polymers—a review. Mater Today Proc 26:405–414. https://doi.org/10.1016/j.matpr.2019.12.067

Sha B, Dimov S, Griffiths C, Packianather MS (2007) Micro-injection moulding: factors affecting the achievable aspect ratios. Int J Adv Manuf Technol 33:147–156. https://doi.org/10.1007/s00170-006-0579-2

Sha B, Dimov S, Pham D (2005) Study of factors affecting aspect ratios achievable in micro-injection moulding. Proc First:1–4

Griffiths CA, Dimov SS, Brousseau EB, Hoyle RT (2007) The effects of tool surface quality in micro-injection moulding. J Mater Process Technol 189:418–427. https://doi.org/10.1016/j.jmatprotec.2007.02.022

Eladl A, Mostafa R, Islam A, Loaldi D, Soltan H, Hansen HN, Tosello G (2018) Effect of process parameters on flow length and flash formation in injection moulding of high aspect ratio polymeric micro features. Micromachines 9. https://doi.org/10.3390/mi9020058

Becker H, Heim U (2000) Hot embossing as a method for the fabrication of polymer high aspect ratio structures. Sensors Actuators A Phys 83:130–135. https://doi.org/10.1016/S0924-4247(00)00296-X

Lin L, Cheng YT, Chiu CJ (1998) Comparative study of hot embossed micro structures fabricated by laboratory and commercial environments. Microsyst Technol 4:113–116. https://doi.org/10.1007/s005420050109

Cirino GA, Granado RM, Mohammed-Brahim T, Jasinevicius RG (2017) Assessment of replication fidelity of optical microstructures by hot embossing. Int J Adv Manuf Technol 88:303–316. https://doi.org/10.1007/s00170-016-8757-3

Crawford RJ (1998) Plastics engineering. Elsevier, Amsterdam. https://doi.org/10.1016/B978-0-7506-3764-0.X5000-6

Groover MP (2019) Fundamentals of modern manufacturing: materials, processes, and systems 7th Edition, Wiley. WileyCom n.d. https://www.wiley.com/en-us/Fundamentals+of+Modern+Manufacturing%3A+Materials%2C+Processes%2C+and+Systems%2C+7th+Edition-p-9781119475217

Lee CS, Kang CG, Youn SW (2010) Effect of forming conditions on linear patterning of polymer materials by hot embossing process. Int J Precis Eng Manuf 11:119–127. https://doi.org/10.1007/s12541-010-0015-2

Shan X, Liu YC, Lam YC (2008) Studies of polymer deformation and recovery in micro hot embossing. Microsyst Technol 14:1055–1060. https://doi.org/10.1007/s00542-007-0486-y

Dib MHM, Colafemina JP (2019) Lentes de Fresnel Anesféricas Versão 2020 - Certificado de Registro de Programa de Computador. 2529. BR512019001216–0

Gao W, Haitjema H, Fang FZ, Leach RK, Cheung CF, Savio E, Linares JM (2019) On-machine and in-process surface metrology for precision manufacturing. CIRP Ann 68:843–866. https://doi.org/10.1016/j.cirp.2019.05.005

Guan B, Cherrill M, Pai JH, Priest C (2019) Effect of mould roughness on injection moulded poly (methyl methacrylate) surfaces: roughness and wettability. J Manuf Process 48:313–319. https://doi.org/10.1016/j.jmapro.2019.10.024

Ligia G, Deodato R (2009) Physicochemical behavior and supramolecular organization of polymers. Springer Netherlands. https://doi.org/10.1007/978-1-4020-9372-2

Acknowledgements

The authors would like to thank IFSP and USP for assistance in this national science public research program and FAPESP for financial support (grant number: 2008/53641-5).

Funding

IFSP and USP supported this work assisting the program of postdoctoral science public research (IFSP postdoctoral number: 23309.001171.2019-13; USP project: 2019 - 987). FAPESP funded this study with financial support (grant number: 2008/53641-5).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, literature review, writing, discussion, data collection, and analysis got performed by João Paulo Colafemina and Renato Goulart Jasinevicius. João Paulo Colafemina and Marcel Dib Militão made the development discussion and concept of the LF2020 software, including its discussion and sketches. João Paulo Colafemina wrote the first draft of the manuscript and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Colafemina, J.P., Militão Dib, M.H. & Jasinevicius, R.G. Hot embossing of aspherical Fresnel microlenses: design, process, and characterization. Int J Adv Manuf Technol 113, 935–953 (2021). https://doi.org/10.1007/s00170-021-06637-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06637-y