Abstract

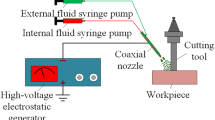

Electrostatic spraying is a new generation of green and efficient cooling/lubrication technique in machining. Critical heat flux reflects the heat transfer potential of electrostatic spraying. In this paper, an evaluation device for cooling capacity of electrostatic spraying is developed to study the effects of voltage, target distance, flow rate of nanofluids, and volume fraction of nanoparticles on critical heat flux by transient heat transfer tests. The electrostatic field between the nozzle and the heat transfer surface is simulated to analyze the heat transfer mechanism. The results show that the critical heat flux is greatly affected by the thermophysical properties of nanofluids, the electric field strength, and the deposition of nanoparticles on the heat transfer surface. Under the cone-jet mode, increasing voltage, flow rate of nanofluids, and volume fraction of nanoparticles and reducing target distance can considerably increase critical heat flux. The maximum critical heat flux can be obtained when the voltage, target distance, flow rate of nanofluids, and volume fraction of nanoparticles are taken as − 8.4 kV, 15 mm, 0.63 ml/min, and 0.15%, respectively.

Similar content being viewed by others

Data availability

Not applicable.

References

Parimalaa N, Mahendrab G, Vamsi Krishnac P (2020) Modelling and simulation of nanofluids to study cooling and lubrication effect. Mater Today Proc 22:2941–2949

Zhang MJ, Tan Y, Zhou FJ, Mao C, Xie ZZ, Li CH (2017) Analysis of flow field in cutting zone for spiral orderly distributed fiber tool. Int J Adv Manuf Technol 92:4345–4354

Chetan GS, Venkateswara Rao P (2015) Application of sustainable techniques in metal cutting for enhanced machinability: a review. J Clean Prod 100:17–34

Su Y (2016) Investigation into the role of cooling/lubrication effect of cryogenic minimum quantity lubrication in machining of AISI H13 steel by three-dimensional finite element method. Proc Inst Mech Eng B J Eng Manuf 230(6):1003–1016

Srikant RR, Prasad MMS, Amrita M, Sitaramaraju AV, Vamsi Krishna P (2014) Nanofluids as potential solution for minimum quantity lubrication: a review. Proc Inst Mech Eng B J Eng Manuf 228:3–20

An QL, Cai CY, Zou F, Liang X, Chen M (2020) Tool wear and machined surface characteristics in side milling Ti6Al4V under dry and supercritical CO2 with MQL conditions. Tribol Int 151:106511

Cai CY, Liang X, An QL, Tao ZR, Ming WW, Chen M (2020) Cooling/lubrication performance of dry and supercritical CO2-based minimum quantity lubrication in peripheral milling Ti-6Al-4V. Int J Pr Eng Man-GT. https://doi.org/10.1007/s40684-020-00194-7

Su Y, Gong L, Li B, Liu ZQ, Chen DD (2016) Performance evaluation of nanofluid MQL with vegetable-based oil and ester oil as base fluids in turning. Int J Adv Manuf Technol 83:2083–2089

Sharif MN, Pervaiz S, Deiab I (2017) Potential of alternative lubrication strategies for metal cutting processes: a review. Int J Adv Manuf Technol 89(5–8):1–33

Jaworek A, Sobczyk AT (2008) Electrospraying route to nanotechnology: an overview. J Electrost 66(3–4):197–219

Maski D, Durairaj D (2010) Effects of electrode voltage, liquid flow rate, and liquid properties on spray chargeability of an air-assisted electrostatic-induction spray-charging system. J Electrost 68(2):152–158

Su Y, Tang ZC, Wan RR (2017) An investigation on the electrostatic atomization mode of nanofluid using cutting tool as electrode. Adv Mech Eng 9(11):1–12

Reddy NSK, Yang M (2010) Development of an electro static lubrication system for drilling of SCM 440 steel. Proc Inst Mech Eng B J Eng Manuf 224(2):217–224

Reddy NSK, Nouari M, Yang M (2010) Development of electrostatic solid lubricant system for improvement in machining process performance. Int J Mach Tool Manu 50(9):789–797

Su Y, Lu Q, Yu T, Liu ZQ, Zhang CY (2019) Machining and environmental effects of electrostatic atomization lubrication in milling operation. Int J Adv Manuf Technol 104:2773–2782

Luchesi VM, Coelho RT (2012) Experimental investigation of heat transfer coefficients of cutting fluids in metal cutting processes: analysis of workpiece phenomena in a given case study. Proc Inst Mech Eng B J Eng Manuf 226:1174–1184

Jiang F, Zhang T, Yan L (2016) Estimation of temperature-dependent heat transfer coefficients in near-dry cutting. Int J Adv Manuf Technol 86:1207–1218

An QL, Dang JQ (2020) Cooling effects of cold mist jet with transient heat transfer on high-speed cutting of titanium alloy. Int J Pr Eng Man-GT 7:271–282

Shabgard M, Seyedzavvar M, Mohammadpourfard M (2017) Experimental investigation into lubrication properties and mechanism of vegetable-based CuO nanofluid in MQL grinding. Int J Adv Manuf Technol 92:3807–3823

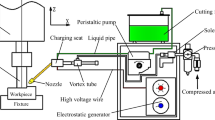

Cao H (2015) Development of nanofluid electrostatic atomization device for green cutting and its atomization characteristic test. Master dissertation, Jiangsu University of Science and Technology, China

Funding

This work was supported by the National Natural Science Foundation of China [grant number 51205177], the Natural Science Foundation of Jiangsu Province [grant numbers BK2012277, BK20171307], and the Natural Science Program for Basic Research of Jiangsu Province [grant number 08KJB460002].

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Su, Y., Jiang, H. & Liu, Z. An experimental investigation on heat transfer performance of electrostatic spraying used in machining. Int J Adv Manuf Technol 112, 1285–1294 (2021). https://doi.org/10.1007/s00170-020-06529-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06529-7