Abstract

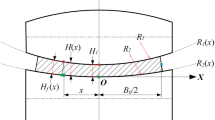

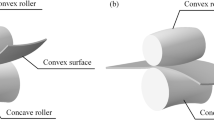

Continuous flexible rolling is a novel plastic forming process for 3D curved parts. In this work, asymmetry forming technology was firstly applied in continuous flexible rolling process, which can effectively compensate the lack of longitude bending deformation caused by work hardening. In the process of asymmetry forming technology, by changing the relative longitude elongation between the tensile surface and compressive surface of the sheet metal, the adjusting of longitudinal bending deformation is achieved. In this paper, the finite element model with different friction ratio was designed; the effect of asymmetry forming technology on longitude curvature radius of 3D curved parts was studied. As results demonstrate that: When the friction ratio between the upper (compressive) and lower (tensile) surface are 0.2:0.2, 0.2:0.15, 0.2:0.10, 0.2:0.05 and 0.2:0.2, 0.15:0.2, 0.10:0.2, 0.05:0.2 in turn, the corresponding longitude curvature radiuses of convex curved parts are 226 mm, 236 mm, 254 mm, 272 mm and 226 mm, 219 mm, 207 mm, 199 mm in turn. When the friction ratio between the upper (tensile) and lower (compressive) surface are 0.2:0.2, 0.2:0.16, 0.2:0.12, 0.2:0.08 and 0.2:0.2, 0.16:0.2, 0.12:0.2, 0.08:0.2 in turn, the corresponding longitude curvature radius of saddle curved parts are 330 mm, 321 mm, 315 mm, 306 mm and 330 mm, 339 mm, 345 mm, 350 mm in turn. The longitude bending deformation of sheet metal can be effectively adjusted in the asymmetry forming technology, so the feasibility of this technology is verified.

Similar content being viewed by others

References

Hansen NE, Tannerup O (1979) Modeling of elastic-plastic bending of beams using a roller bending machine[J]. J Manuf Sci Eng 101(3):304–310

山下勇, 加藤和典, 遠藤順一 (1986). 可撓ロールによる複曲面成形加工の研究 (第 1 報 可撓べンデイングロール機の試作)[C]. 日本塑性加工学会. 第 37 回塑性加工連合講演会論文集, 横浜, 1986:345–348

Kim TJ, Yang DY (2000) Improvement of formability for the incremental rolled plate forming process[J]. Int J Mech Sci 42(7):1271–1286

Yamashita I, Yamakawa T (1988) Apparatus for forming plate with a double-curved surface. United States, 4770017[P], 1988-11-13

Yoon SJ, Yang DY (2003) Development of a highly flexible incremental roll forming process for the manufacture of a doubly curved rolled plate[J]. CIRP Ann Manuf Technol 52(1):201–204

Yoon SJ, Yang DY (2005) An incremental roll forming process for manufacturing doubly curved sheets from general quadrilateral sheet blanks with enhanced process features[J]. CIRP Ann-Manuf Technol 54(1):221–224

Shim DS, Yang DY, Han MS, Chung SW, Kim KH, Roh HJ (2008) Experimental study on manufacturing doubly curved plates using incremental rolling process[C]. ICTP 2008 (The 9th International Conference on Technology of Plasticity), Gyeongju

Shim DS, Yang DY, Kim KH, Chung SW, Han MS (2010) Investigation into forming sequences for the incremental forming of doubly curved plates using the line array roll set (LARS) process[J]. Int J Mach Tools Manuf 50(2):214–218

Cai ZY, Sui Z, Cai FX, Liu L (2013) Continuous flexible roll forming for doubly curved part and the forming process control. Int J Adv Manuf Technol 66:393–400

Cai ZY, Li MZ (2013) Principle and theoretical analysis of continuous roll forming for doubly curved part. SCIENCE CHINA Technol Sci 56:351–358

Li RJ, Li MZ, Qiu NJ, Cai ZY (2014) Surface continuous roll forming process for three-dimensional rolled plate parts. J Mater Process Technol 214:380–389

Cai ZY, MiW LMZ (2014) Study on the continuous roll forming process of swept surface rolled plate part. J Mater Process Technol 204(9):1820

Li MZ, Cai ZY, Li RZ, Lan YW, Qiu NJ (2012) Continuous forming method for doubly curved part based on the rolling process using bended roll. Chin J Mech Eng 48:44

Li Y, Li MZ, Liu K (2018) Study on the utilization rate of processed spherical surface part in flexible rolling[J]. Int J Adv Manuf Technol 100:3207

Li Y, Li M, Liu K et al (2018) Effect of differential speed rotation technology on the forming uniformity in flexible rolling process[J]. Materials (Basel) 11(10):1906

Li Y, Li MZ, Liu K (2019) Influence of a multi-step process on the thickness reduction error of rolled plate in a flexible rolling process[J]. Int J Miner Metall Mater 26:76–85

Li Y, Li MZ (2019) Effect of incremental multi-step technology on longitude bending of 3D curved part in continuous flexible rolling process[J]. Int J Adv Manuf Technol 105:1777

Funding

This study was supported by Program for Innovative Research Team of Jilin Engineering Normal University. Financial assistance for this study was provided by the National Natural Science Foundation of China (no. 51275202).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Yuan, Hy. & Li, Mz. Effect of asymmetry forming technology on longitude curvature radius of 3D curved part in continuous flexible rolling process. Int J Adv Manuf Technol 112, 2081–2090 (2021). https://doi.org/10.1007/s00170-020-06434-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06434-z