Abstract

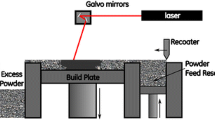

As an additive manufacturing technology, selective laser melting (SLM) can form any complex metal parts, which has unparalleled advantages compared to traditional processing methods. However, there are still some problems such as accuracy and non-repeatability to overcome to apply SLM to production practice. The high-precision monitoring and degradation feedback technology of SLM equipment is the future development direction. The real-time monitoring machine can repair itself and avoid the tedious detection in the post-processing stage. The researchers mainly monitor the quality of the forming process by molten pool signal, temperature signal, sound signal, and scanning track. The forming process is monitored using coaxial detection or paraxial detection through a high-speed camera, pyrometer, and other equipment. This paper can provide theoretical support for the SLM intelligent monitoring field.

Similar content being viewed by others

References

Gunasekaran J, Sevvel P, John Solomon I (2020) Metallic materials fabrication by selective laser melting: a review. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.05.162

Zhang C, Zhu J, Zheng H, Li H, Liu S, Cheng GJ (2020) A review on microstructures and properties of high entropy alloys manufactured by selective laser melting. Int J Extreme Manuf 2:32003. https://doi.org/10.1088/2631-7990/ab9ead

Craeghs T, Bechmann F, Berumen S, Kruth JP (2010) Feedback control of layerwise laser melting using optical sensors. Phys Procedia 5:505–514. https://doi.org/10.1016/j.phpro.2010.08.078

Everton SK, Hirsch M, Stravroulakis P, Leach RK, Clare AT (2016) Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater Des 95:431–445. https://doi.org/10.1016/j.matdes.2016.01.099

Grasso M, Demir AG, Previtali B, Colosimo BM (2018) In situ monitoring of selective laser melting of zinc powder via infrared imaging of the process plume. Robot Comput Integr Manuf 49:229–239. https://doi.org/10.1016/j.rcim.2017.07.001

Gusarov AV, Smurov I (2009) Two-dimensional numerical modelling of radiation transfer in powder beds at selective laser melting. Appl Surf Sci 255:5595–5599. https://doi.org/10.1016/j.apsusc.2008.07.202

Shiomi M, Osakada K, Nakamura K, Yamashita T, Abe F (2004) Residual stress within metallic model made by selective laser melting process. CIRP Ann 53:195–198. https://doi.org/10.1016/S0007-8506(07)60677-5

Spears TG, Gold SA (2016) In-process sensing in selective laser melting (SLM) additive manufacturing. Integr Mater Manuf Innov 5:16–40. https://doi.org/10.1186/s40192-016-0045-4

Van EM (2007) Complexity of selective laser melting: a new optimisation approach. Dissertation, Katholieke Universiteit Leuven. https://limo.libis.be/primoexplore/fulldisplay?docid=LIRIAS1746431&context=L&vid=Lirias&search_scope=Lirias&tab=default_tab&lang=en_US. Accessed 10 Oct 2020

Thijs L, Verhaeghe F, Craeghs T, Humbeeck JV, Kruth JP (2010) A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater 58:3303–3312. https://doi.org/10.1016/j.actamat.2010.02.004

Grasso M, Colosimo B (2017) Process defects and in-situ monitoring methods in metal powder bed fusion: a review. Meas Sci Technol 28:1–25. https://doi.org/10.1088/1361-6501/aa5c4f

Yang J, Han J, Yu H, Yin JGM, Wang Z, Zeng X (2016) Role of molten pool mode on formability, microstructure and mechanical properties of selective laser melted Ti-6Al-4V alloy. Mater Des 110:558–570. https://doi.org/10.1016/j.matdes.2016.08.036

Khairallah SA, Anderson AT, Rubenchik A, King WE (2016) Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45. https://doi.org/10.1016/j.actamat.2016.02.014

Criales LE, Arısoy YM, Lane B, Moylan S, Donmez A, Özel T (2017) Laser powder bed fusion of nickel alloy 625: experimental investigations of effects of process parameters on melt pool size and shape with spatter analysis. Int J Mach Tools Manuf. 121:22–36. https://doi.org/10.1016/j.ijmachtools.2017.03.004

Foster B, Reutzel E, Nassar A, Hall B, Brown S, Dickman C (2015) 2015 Annual Solid Freeform Fabrication, Austin. In: University of Texas at Austin, pp 295–307. View Record in Scopus (https://www.scopus.com/record/display.uri?eid=2-s2.0-84981188889&origin=inward&txGid=9ac2b1abe9d6a36a40df1464e086c7b2) Google Scholar (https://scholar.google.com/scholar_lookup?title=Optical%2C%20layerwise%20monitoring%20of%20powder%20bed%20fusion&publication_year=2015&author=B.K.%20Foster&author=E.W.%20Reutzel&author=A.R.%20Nassar&author=B.T.%20Hall&author=S.W.%20Brown&author=C.J.%20Dickman. Accessed 10 Oct 2020

Mani M, Donmez M, Feng S, Moylan S, Fesperman R, Lane B (2015) Measurement science needs for real-time control of additive manufacturing powder bed fusion processes. https://doi.org/10.6028/NIST.IR.8036

Gibson BT, Bandari YK, Richardson BS, Henry WC, Vetland EJ, Sundermann TW, Love LJ (2020) Melt pool size control through multiple closed-loop modalities in laser-wire directed energy deposition of Ti-6Al-4V. Addit Manuf 32:100993. https://doi.org/10.1016/j.addma.2019.100993

Gibson B, Bandari YK, Richardson B, Roschli A, Post B, Borish M, Thornton AS, Henry WC, Lamsey MD, Love L (2019) Melt pool monitoring for control and data analytics in large-scale metal additive manufacturing. United States. https://www.osti.gov/biblio/1561633. Accessed 10 Oct 2020

Nassar AR, Reutzel EW, Brown SW Jr, John PM, Morgan JP, Natale DJ, Tutwiler RL, Feck DP, Banks JC (2016) Sensing for directed energy deposition and powder bed fusion additive manufacturing at Penn State University. In: Proc.SPIE. https://doi.org/10.1117/12.2217855

Rodriguez E, Medina F, Espalin D, Terrazas C, Muse D, Henry C, Macdonald E, Wicker RB (2012) Integration of a thermal imaging feedback control system in electron beam melting. In: 23rd Annu Int Solid Free Fabr Symp - An Addit Manuf Conf SFF 2012, pp 945–961

Chivel Y, Smurov I (2010) On-line temperature monitoring in selective laser sintering/melting. Phys Procedia 5:515–521. https://doi.org/10.1016/j.phpro.2010.08.079

Pavlov M, Doubenskaia M, Smurov I (2010) Pyrometric analysis of thermal processes in SLM technology. Phys Procedia 5:523–531. https://doi.org/10.1016/j.phpro.2010.08.080

Doubenskaia M, Pavlov M, Chivel Y (2010) Optical system for on-line monitoring and temperature control in selective laser melting technology. Key Eng Mater 437:458–461. https://doi.org/10.4028/www.scientific.net/KEM.437.458

Doubenskaia M, Pavlov M, Grigoriev S, Tikhonova E, Smurov I (2012) Comprehensive optical monitoring of selective laser melting. J Laser Micro / Nanoeng 7:236–243. https://doi.org/10.2961/j1mn.2012.03.001

Berumen S, Bechmann F, Lindner S, Kruth JP, Tom C (2010) Quality control of laser-and powder bed-based additive manufacturing (AM) technologies. Phys Procedia 5:617–622. https://doi.org/10.1016/j.phpro.2010.08.089

Clijsters S, Craeghs T, Buls S, Kempen K, Kruth JP (2014) In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. Int J Adv Manuf Technol 75:1089–1101. https://doi.org/10.1007/s00170-014-6214-8

Craeghs T, Clijsters S, Yasa E, Bechmann F, Berumen S, Kruth JP (2011) Determination of geometrical factors in l.ayerwise laser melting using optical process monitoring. Opt Lasers Eng 49:1440–1446. https://doi.org/10.1016/j.optlaseng.2011.06.016

Craeghs T, Clijsters S, Kruth JP, Bechmann F, Ebert MC (2012) Detection of process failures in layerwise laser melting with optical process monitoring. Phys Procedia 39:753–759. https://doi.org/10.1016/j.phpro.2012.10.097

Yadroitsev I, Krakhmalev P, Yadroitsava I (2014) Selective laser melting of Ti6Al4V alloy for biomedical applications: temperature monitoring and microstructural evolution. J Alloys Compd 583:404–409. https://doi.org/10.1016/j.jallcom.2013.08.183

Lott P, Schleifenbaum H, Meiners W, Wissenbach K, Hinke C, Bültmann J (2011) Design of an optical system for the in situ process monitoring of selective laser melting (SLM). Phys Procedia 12:683–690. https://doi.org/10.1016/j.phpro.2011.03.085

Thombansen U, Gatej A, Pereira M (2014) Process observation in fiber laser–based selective laser melting. Opt Eng 54:11008. https://doi.org/10.1117/1.OE.54.1.011008

Fercher AF, Drexler W, Hitzenberger CK, Lasser T (2003) Optical coherence tomography - principles and applications. Rep Prog Phys 66:239–303. https://doi.org/10.1088/0034-4885/66/2/204

Kanko JA, Sibley AP, Fraser JM (2016) In situ morphology-based defect detection of selective laser melting through inline coherent imaging. J Mater Process Technol 231:488–500. https://doi.org/10.1016/j.jmatprotec.2015.12.024

Neef A, Seyda V, Herzog D, Emmelmann C, Schönleber M, Kogel-Hollacher M (2014) Low coherence interferometry in selective laser melting. Phys Procedia 56:82–89. https://doi.org/10.1016/j.phpro.2014.08.100

Krauss H, Eschey C, Zaeh MF (2012) Thermography for monitoring the selective laser melting process. In: 23rd International Solid Freeform Fabrication Symposium; Austin, TX. https://api.semanticscholar.org/CorpusID:201858857. Accessed 10 Oct 2020. Google Scholar (https://scholar.google.com/scholar_lookup?title=Thermography%20for%20monitoring%20the%20selective%20laser%20melting%20process&publication_year=2012&author=H.%20Krauss&author=C.%20Eschey&author=M.F.%20Zaeh)

Kleszczynski S, Zur Jacobsmühlen J, Sehrt JT, Witt G (2012) Error detection in laser beam melting systems by high resolution imaging. In: 23rd Annu. Int. Solid Free. Fabr. Symp. University of Texas at Austin, Austin, pp 975–987. Google Scholar (https://scholar.google.com/scholar?hl=zh-CN&as_sdt=2005&sciodt=0%2C5&cites=3082008579271783940&scipsc=&q=Error+detection+in+laser+beam+melting+systems+by+high+resolution+imaging&btnG=)

Jacobsmühlen JZ, Kleszczynski S, Schneider D, Witt G (2013) High resolution imaging for inspection of laser beam melting systems. In: 2013 IEEE international instrumentation and measurement technology conference (I2MTC), 6–9 May 2013 (pp 707–712). https://doi.org/10.1109/I2MTC.2013.6555507. Google Scholar (https://hk7096.scholar.eu.org/scholar?hl=zh-CN&as_sdt=0%2C5&q=High+resolution+imaging+for+inspection+of+laser+beam+melting+systems&btnG=)

Jacobsmühlen JZ, Kleszczynski S, Witt G, Merhof D (2015) Elevated region area measurement for quantitative analysis of laser beam melting process stability. In: 26th International solid freeform fabrication symposium, Austin, TX. Google Scholar (https://xueshu.lanfanshu.cn/scholar?hl=zh-CN&as_sdt=2005&sciodt=0%2C5&scipsc=&q=Elevated+Region+Area+Measurement+for+Quantitative+Analysis+of+Laser+Beam+Melting+Process+Stability&btnG=)

Jacobsmühlen JZ, Kleszczynski S, Witt G, Merhof D (2015) Detection of elevated regions in surface images from laser beam melting processes. In: 41st Annual conference of the IEEE Industrial Electronics Society. Google Scholar (https://hk7096.scholar.eu.org/scholar?hl=zh-CN&as_sdt=0%2C5&q=Detection+of+elevated+regions+in+surface+images+from+laser+beam+melting+processes&btnG=)

Hirvimäki M, Manninen M, Lehti A, Happonen A, Salminen A, Nyrhilä O (2013) Evaluation of different monitoring methods of laser additive manufacturing of stainless steel. Adv Mater Res 651:812–819. https://doi.org/10.4028/www.scientific.net/AMR.651.812

Zhao C, Fezzaa K, Cunningham RW, Wen H, Carlo FD, Chen L, Rollett AD, Sun T (2017) Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction. Sci Rep 7:1–11. https://doi.org/10.1038/s41598-017-03761-2

Craeghs T, Clijsters S, Yasa E, Kruth J-P (2011) Online quality control of selective laser melting. In: 22nd Annu. Int. Solid Free. Fabr. Symp. - An Addit. Manuf. Conf. SFF 2011. University of Texas at Austin (freeform), Austin, pp 212–226. Google Scholar (https://xueshu.lanfanshu.cn/scholar?hl=zh-CN&as_sdt=2005&sciodt=0%2C5&scipsc=&q=Online+quality+control+of+selective+laser+melting&btnG=). Accessed 10 Oct 2020

Bayle F, Doubenskaia M (2008) Selective laser melting process monitoring with high speed infra-red camera and pyrometer - art. no. 698505. In: Proc SPIE, vol 6985. https://doi.org/10.1117/12.786940

Repossini G, Laguzza V, Grasso M, Colosimo BM (2017) On the use of spatter signature for in-situ monitoring of laser powder bed fusion. Addit Manuf 16:35–48. https://doi.org/10.1016/j.addma.2017.05.004

Furumoto T, Alkahari MR, Ueda T, Aziz MSA, Hosokawa A (2012) Monitoring of laser consolidation process of metal powder with high speed video camera. Phys Procedia 39:760–766. https://doi.org/10.1016/j.phpro.2012.10.098

Islam M, Purtonen T, Piili H, Salminen A, Nyrhilä O (2013) Temperature profile and imaging analysis of laser additive manufacturing of stainless steel. Phys Procedia 41:835–842. https://doi.org/10.1016/j.phpro.2013.03.156

Kruth JP, Froyen L, Van Vaerenbergh J, Mercelis P, Rombouts M, Lauwers B (2004) Selective laser melting of iron-based powder. J Mater Process Technol 149:616–622. https://doi.org/10.1016/j.jmatprotec.2003.11.051

Krauss H, Zeugner T, Zaeh MF (2014) Layerwise monitoring of the selective laser melting process by thermography. Phys Procedia 56:64–71. https://doi.org/10.1016/j.phpro.2014.08.097

Krauss H, Zeugner T, Zaeh M (2015) Thermographic process monitoring in powderbed based additive manufacturing. AIP Conf Proc 1650:177–183. https://doi.org/10.1063/1.4914608

Abdelrahman M, Reutzel EW, Nassar AR, Starr TL (2017) Flaw detection in powder bed fusion using optical imaging. Addit Manuf 15:1–11. https://doi.org/10.1016/j.addma.2017.02.001

Ye DS, Hong GS, Zhang YJ, Zhu KP, Fuh JYH (2018) Defect detection in selective laser melting technology by acoustic signals with deep belief networks. Int J Adv Manuf Technol 96:2791–2801. https://doi.org/10.1007/s00170-018-1728-0

Leung CLA, Marussi S, Atwood RC, Towrie M, Withers PJ, Lee PD (2018) In situ X-ray imaging of defect and molten pool dynamics in laser additive manufacturing. Nat Commun 9:1355. https://doi.org/10.1038/s41467-018-03734-7

Boaretto N, Centeno TM (2017) Automated detection of welding defects in pipelines from radiographic images DWDI. NDT E Int 86:7–13. https://doi.org/10.1016/j.ndteint.2016.11.003

Yuan B, Giera B, Guss G, Matthews M, McMains S, (2019) Semi-supervised convolutional neural networks for in-situ video monitoring of selective laser melting. 2019 IEEE Winter Conference on Applications of Computer Vision (WACV). IEEE, 2019. https://doi.org/10.1109/WACV.2019.00084

Scime L, Beuth J (2018) Anomaly detection and classification in a laser powder bed additive manufacturing process using a trained computer vision algorithm. Addit Manuf 19:114–126. https://doi.org/10.1016/j.addma.2017.11.009

Scime L, Beuth J (2018) A multi-scale convolutional neural network for autonomous anomaly detection and classification in a laser powder bed fusion additive manufacturing process. Addit Manuf 24:273–286. https://doi.org/10.1016/j.addma.2018.09.034

Hoffman J, Szyma ski Z (2004) Time-dependent spectroscopy of plasma plume under laser welding conditions. J Phys D Appl Phys 37:1792–1799. https://doi.org/10.1088/0022-3727/37/13/010

Wang D, Wu S, Fu F, Mai S, Yang Y, Liu Y, Song C (2017) Mechanisms and characteristics of spatter generation in SLM processing and its effect on the properties. Mater Des 117:121–130. https://doi.org/10.1016/j.matdes.2016.12.060

Grasso M, Colosimo BM (2019) A statistical learning method for image-based monitoring of the plume signature in laser powder bed fusion. Robot Comput Integr Manuf 57:103–115. https://doi.org/10.1016/j.rcim.2018.11.007

Yang D, Li H, Liu S, Song C, Yang Y, Shen S, Lu J, Liu Z, Zhu Y (2020) In situ capture of spatter signature of SLM process using maximum entropy double threshold image processing method based on genetic algorithm. Opt Laser Technol 131:106371. https://doi.org/10.1016/j.optlastec.2020.106371

Kwon O, Kim HG, Ham MJ, Kim W, Kim GH, Cho JH, Kim NI, Kim K (2020) A deep neural network for classification of melt-pool images in metal additive manufacturing. J Intell Manuf 31:375–386. https://doi.org/10.1007/s10845-018-1451-6

Acknowledgments

This work was supported by grants 51875010 and 51875005 from the National Natural Science Foundation of China. The authors gratefully acknowledge their financial support.

Funding

This research was funded by the National Natural Science Foundation of China Grant Number 51875010 and 51875005.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, D., Wang, P., Pan, R. et al. Research on in situ monitoring of selective laser melting: a state of the art review. Int J Adv Manuf Technol 113, 3121–3138 (2021). https://doi.org/10.1007/s00170-020-06432-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06432-1