Abstract

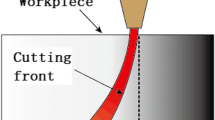

As the only cold high-energy beam machining technology, abrasive water jet (AWJ) has a very broad application prospect in material manufacturing industry. However, the application of AWJ is limited by the machining accuracy it can be achieved. To get higher accuracy in the AWJ cutting process, a better understanding of the cutting front is necessary since the machining accuracy is decided by the cutting front of AWJ. In this paper, the influence of machining parameters on the cutting front profile has been investigated. Based on the investigation, the cutting front profile model has been built and verified. With this mathematical model, predicting the cutting front profile accurately according to the cutting conditions becomes feasible and practical, which further leads to higher precision cutting of AWJ.

Similar content being viewed by others

References

Chen M, Zhang S, Zeng J, Chen B, Xue J, Ji L (2019) Correcting shape error on external corners caused by the cut-in/cut-out process in abrasive water jet cutting. Int J Adv Manuf Technol 103(1-4):849–859

Chen M, Zhang S, Zeng J, Chen B (2019) Correcting shape error located in cut-in/cut-out region in abrasive water jet cutting process. Int J Adv Manuf Technol 102(5–8):1165–1178

Hashish M (2006) Enhanced abrasive waterjet cutting accuracy with dynamic tilt compensation. CRIP 2nd International Conference on High Performance Cutting, Vancouver, British Columbia, 12–13 June 2006

Zhang S, Wu Y, Wang S (2015) An exploration of an abrasive water jet cutting front profile. Int J Adv Manuf Technol 80(9–12):1685–1688

Henning A, Westkämper E (2006) Analysis of the cutting front in abrasive waterjet cutting. Proceedings of the 18th international conference on water jetting, Gdansk, pp 425–434

Hashish M (1988) Visualization of the abrasive waterjet cutting process. Exp Mech 28(2):159–169

Matsui S, Matsumura H, Ikemoto Y, Tsujita K, Shimizu H (1990) High precision cutting method for metallic materials by abrasive waterjet. Proceedings of the 10th International Symposium, Amsterdam, pp 263–278

Zeng J, Heines R, Kim TJ (1991) Characterization of energy dissipation phenomenon in abrasive waterjet cutting. Proceedings of the 6th American waterjet conference, Houston, Texas, pp 163–177

Kitamura M, Ishikawa M, Sudo K (1992) Cutting of steam turbine components using an abrasive water jet. Jet Cut Technol. Springer Netherlands 1992:543–554

Hashish M (2007) Benefits of dynamic waterjet angle compensation. 2007 American WJTA Conference and Expo, Houston, Texas, 1-H

Henning A, Westkamper E, Schmidt B (2004) Analysis of geometry at abrasive waterjet cutting operation. Proceedings of the 17th international conference on water jetting-advances and future needs, Mainz, pp 465–474

Gostimirovic M, Pucovsky V, Sekulic M, Rodic D, Pejic V (2019) Evolutionary optimization of jet lag in the abrasive water jet machining. Int J Adv Manuf Technol 101:3131–3141

Akkurt A (2010) Cut front geometry characterization in cutting applications of brass with abrasive water jet. J Mater Eng Perform 19(4):599–606

Wu Y, Zhang S, Wang S, Yang F, Tao H (2015) Method of obtaining accurate jet lag information in abrasive water-jet machining process. Int J Adv Manuf Technol 76(9-12):1827–1835

Jerman M, Valentincic J, Lebar A, Orbanic H (2015) The study of abrasive water jet cutting front development using a two-dimensional cellular automata model. Strojniski Vestnik 61(5):292–302

Mital G, Dobránsky J, Ružbarský J, Olejárová Š (2019) Application of laser profilometry to evaluation of the surface of the workpiece machined by abrasive waterjet technology. Appl Sci 9(10):2134

Zeng J (2007) Determination of machinability and abrasive cutting properties in AWJ cutting. 2007 American WJTA Conference and Expo, Houston, Texas, pp 19–21

Zeng J, Kim TJ, Wallace RJ (1992) Quantitative evaluation of machinability in abrasive waterjet machining. 1992 Winter Annual Meeting of ASME, “Precision Machining: Technology and Machine Development and Improvement”, PED-Vol.58, Anaheim, pp 169–179

Zeng J (1992) Mechanisms of brittle material erosion associated with high pressure abrasive waterjet processing-a modeling and application study. University of Rhode Island, Dissertation

Acknowledgments

This research was supported by the Natural Science Foundation of Hunan Province (2018JJ3253 and 2020JJ5273), the Hunan Provincial Department of Education Project (18B462, 18A419 and 19B298), and the Hunan Province Key Area R&D Program (2019SK2192).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, S., Hu, D., Yang, F. et al. Exploring cutting front profile in abrasive water jet machining of aluminum alloys. Int J Adv Manuf Technol 112, 845–851 (2021). https://doi.org/10.1007/s00170-020-06379-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06379-3