Abstract

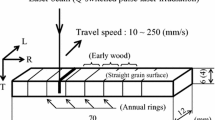

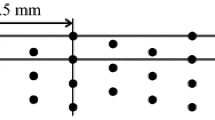

This paper presents experimental and theoretical studies on the UV laser cutting of beech plywood. The multi-technological factors in the laser cutting process were determined using Taguchi’s parameter design approach. The study of the wood material after laser cutting, related to its microstructure, surface morphology, and surface energy, is included. Beech plywood components were cut using pulsed UV lasers with varying parameters to determine superior surface quality, based on SEM, gray level, water contact angle, and optical profiling. The results showed that the surface roughness, in Ra, of beech plywood components at different laser powers, with and without a gas flux control system, can be reduced from 17.3 to 11.1 μm. The burn marks of the laser cut samples were also characterized in terms of gray level estimation. The results indicated that the gray level of the samples was increased by about 16% with a gas flux control system, implying a lesser extent of the burn marks in the plywood. The proposed laser cutting approach was proven to be successful in controlling the surface finish quality of beech plywood components.

Similar content being viewed by others

Data availability

Not applicable.

References

Belforte DA (1998) Non-metalcutting. Ind Laser Rev 13(9):11–13

Eltawahni HA, Rossini NS, Dassisti M, Alrashed K, Aldaham TA, Benyounis KY, Olabi AG (2013) Evalaution and optimization of laser cutting parametersfor plywood materials. Opt Lasers Eng 51(9):1029–1043. https://doi.org/10.1016/j.optlaseng.2013.02.019

Barcikowski S, Koch G, Odermatt J (2006) Characterisation and modification of the heat affected zone during laser material processing of wood and wood composites. Holz Roh-Und Werkst 64:94–103. https://doi.org/10.1007/s00107-005-0028-1

Martinez-Conde A, Krenke T, Frybort S, Müller U (2017) Review: Comparative analysis of CO2 laser and conventional sawing for cutting of lumber and wood-based materials. Wood Sci Technol 51(4):943–966. https://doi.org/10.1007/s00226-017-0914-9

Hernandez JC, Crouse P, Li L (2007) High-power Yb-doped fibre laser for cutting dry pine wood. In: World Congress on Engineering, pp 1129-1134

Yang CM, Zhu XL, Kim NH, Lee SH, Qi Y, Bai Y, Guo MH, Ma Y (2016) Experimental design and study of micro-nano wood fiber processed by nanosecond pulse laser. Bioresources 11(4):8215–8225. https://doi.org/10.15376/biores.11.4.8215-8225

Fukuta S, Nomura M, Ikeda T, Yoshizawa M, Yamasaki M, Sasaki Y (2016) UV laser machining of wood. Eur J Wood Wood Prod 74(2):261–267

Quintero F, Riveiro A, Lusquinos F, Comesana R, Pou J (2011) CO2 laser cutting of phenolic resin boards. J Mater Process Technol 211(11):1710–1718

Pandey KK, Vuorinen T (2008) UV resonance Raman spectroscopic study of photodegradation of hardwood and softwood lignins by UV laser. Holzforschung 62(2):183–188. https://doi.org/10.1515/Hf.2008.046

Zhou BH, Mahdavian SM (2004) Experimental and theoretical analyses of cutting nonmetallic materials by low power CO2-laser. J Mater Process Technol 146(2):188–192. https://doi.org/10.1016/j.jmatprotec.2003.10.017

Eltawahni HA, Olabi AG, Benyounis KY (2011) Investigating the CO2 laser cutting parameters of MDF wood composite material. Opt Laser Technol 43(3):648–659. https://doi.org/10.1016/j.optlastec.2010.09.006

Barnekov VG, Mcmillin CW, Huber HA (1986) Factors influencing laser cutting of wood. For Prod J 36(1):55–58

Molnar S, Nemeth R, Feher S, Tolvaj L, Papp G, Varga F, Apostol T (2001) Technical and technological properties of hungarian beech wood consider the red heart. Drev Vysk 46(1):21–29

Randall WK (1977) Growth correlations of cottonwood clones developed from mature wood cuttings. Silvae Genet 26(2-3):119–120

Schuler JL, McCarthy W (2015) Development of eastern cottonwood cuttings as modified by cutting length and surface area available for rooting. New Forest 46(4):547–559

Hirata S, Ohta M, Honma Y (2001) Hardness distribution on wood surface. J Wood Sci 47(1):1–7. https://doi.org/10.1007/Bf00776637

Lum KCP, Ng SL, Black I (2000) CO2 laser cutting of MDF 1. Determination of process parameter settings. Opt Laser Technol 32(1):67–76

Hernandez-Castaneda JC, Sezer HK, Li L (2011) The effect of moisture content in fibre laser cutting of pine wood. Opt Lasers Eng 49(9-10):1139–1152

Fukuta S, Nomura M, Ikeda T, Yoshizawa M, Yamasaki M, Sasaki Y (2016) Wavelength dependence of machining performance in UV-, VIS- and NIR-laser cutting of wood. J Wood Sci 62(4):316–323

Leone C, Genna S, Caggiano A, Tagliaferri V, Molitierno R (2015) An investigation on Nd:YAG laser cutting of Al 6061 T6 alloy sheet. 3rd Cirp Global Web Conference - Production Engineering Research Advancement Beyond State of the Art (Cirpe2014) 28:64-69. https://doi.org/10.1016/j.procir.2015.04.012

Hazir E, Koc KH (2019) Optimization of wood machining parameters in Cnc routers: Taguchi orthogonal array based simulated angling algorithm. Maderas-Cienc Tecnol 21(4):493–510

Zaidon A, Kim GH, Bakar ES, Rasmina H (2014) Response surface methodology models of processing parameters for high performance phenolic compreg wood. Sains Malays 43(5):775–782

Hao HJ, Wang ML, Hao FQ (2012) Multi-objective optimization of quality in laser cutting based on response surface model. Proceedings of the 2nd International Conference on Computer and Information Applications (Iccia 2012):1271-1274

Jou YT, Lin WT, Lee WC, Yeh TM (2014) Integrating the Taguchi method and response surface methodology for process parameter optimization of the injection molding. Appl Math Inform Sci 8(3):1277–1285. https://doi.org/10.12785/amis/080342

Kubovsky I, Kacik F, Reinprecht L (2016) The impact of UV radiation on the change of colour and composition of the surface of lime wood treated with a CO2 laser. J Photoch Photobio A 322:60–66. https://doi.org/10.1016/j.jphotochem.2016.02.022

Yuce MY, Demirel AL, Menzel F (2005) Tuning the surface hydrophobicity of polymer/nanoparticle composite films in the wenzel regime by composition. Langmuir 21(11):5073–5078. https://doi.org/10.1021/la050033y

Deng YB, Mager D, Bai Y, Zhou T, Liu ZY, Wen LP, Wu YH, Korvink JG (2018) Inversely designed micro-textures for robust Cassie-Baxter mode of super-hydrophobicity. Comput Method Appl M 341:113–132. https://doi.org/10.1016/j.cma.2018.06.034

Hubbe MA, Gardner DJ, Shen W (2015) Contact angles and wettability of cellulosic surfaces: a review of proposed mechanisms and test strategies. Bioresources 10(4):8657–8749

Kutnar A, Rautkari L, Laine K, Hughes M (2012) Thermodynamic characteristics of surface densified solid Scots pine wood. Eur J Wood Wood Prod 70(5):727–734. https://doi.org/10.1007/s00107-012-0609-8

Jennings JD, Zink-Sharp A, Kamke FA, Frazier CE (2005) Properties of compression densified wood. Part 1: bond performance. J Adhes Sci Technol 19(13-14):1249–1261. https://doi.org/10.1163/156856105774429055

Englund F, Bryne LE, Ernstsson M, Lausmaa J, Walinder M (2009) Spectroscopic studies of surface chemical composition and wettability of modified wood. Wood Mater Sci Eng 4:80–85. https://doi.org/10.1080/17480270903337659

Huang XA, Kocaefe D, Kocaefe Y, Boluk Y, Pichette A (2012) Changes in wettability of heat-treated wood due to artificial weathering. Wood Sci Technol 46(6):1215–1237. https://doi.org/10.1007/s00226-012-0479-6

Gunnells DW, Gardner DJ, Wolcott MP (1994) Temperature-dependence of wood surface-energy. Wood Fiber Sci 26(4):447–455

Cheng EZ, Sun X (2006) Effects of wood-surface roughness, adhesive viscosity and processing pressure on adhesion strength of protein adhesive. J Adhes Sci Technol 20(9):997–1017. https://doi.org/10.1163/156856106777657779

Hiziroglu S, Zhong ZW, Ong WK (2014) Evaluating of bonding strength of pine, oak and nyatoh wood species related to their surface roughness. Measurement 49:397–400. https://doi.org/10.1016/j.measurement.2013.11.053

Spuhler GJ, Sudmeyer T, Paschotta R, Moser M, Weingarten KJ, Keller U (2000) Passively mode-locked high-power Nd : YAG lasers with multiple laser heads. Appl Phys B-Lasers O 71(1):19–25

Wu YJ, Gao YQ, Zheng Q, Ji LL, Cui Y, Li FJ, Hua YL, Ma WX, Sui Z (2020) Design and analysis of thermal stable regenerative cavity with multiple laser heads using 4f system. Opt Eng 59(3):Artn 036111. https://doi.org/10.1117/1.Oe.59.3.036111

Corboline T, Rea EC, Dunsky C (2003) High power UV laser machining of silicon wafers. Fourth International Symposium on Laser Precision Microfabrication 5063:495-500. https://doi.org/10.1117/12.540931

Tonshoff HK, Overmeyer L, Ostendorf A, Wais J (1997) General machining concept for producing micro-optics with high-power UV-lasers. Excimer Lasers Optics Appl 2992:150–158

Funding

This work was funded by The Hong Kong Polytechnic University under project number P17-0449.

Author information

Authors and Affiliations

Contributions

HSC wrote the manuscript and collected the data. KCY, TX, and ZC collected the data and contributed to the writing of the text. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

All authors consented to the publication.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yung, K., Choy, H., Xiao, T. et al. UV laser cutting of beech plywood. Int J Adv Manuf Technol 112, 925–947 (2021). https://doi.org/10.1007/s00170-020-06376-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06376-6