Abstract

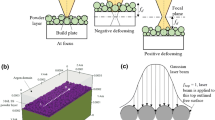

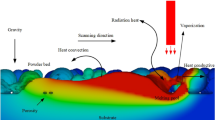

Rapid melting and solidification of powder particles through a high-power laser is the characteristic feature of selective laser melting (SLM), which controls the material and physical properties of fabricated components. Considering the multi-track multi-layer nature of an actual SLM process, an investigation of thermal behavior and melt pool morphology in multi-track multi-layer SLM of the 316L steel is presented in this paper. The SLM process of a four-layer component with multiple tracks was modeled. Element birth and death technique was used to simulate the layer built-up process. The established FEM model was used to investigate the variations in thermal variables and melt pool morphology with increasing number of layers. Moreover, the influence of various processing parameters in a multi-track multi-layer SLM was also studied. The results show that maximum melt pool temperature, melt pool width, and melt pool depth increase with increasing number of layers, whereas heating rates and cooling rates decrease with increasing number of layers. Compared with the previous layer, melt pool lifetime was observed to have a decreasing trend for layer 2 and increasing trend for layers 3 and 4. An increase in melt pool depth and decrease in melt pool width was observed by increasing hatch spacing. Furthermore, it was found that increasing laser power and scanning speeds both increase the heating and cooling rates.

Similar content being viewed by others

References

Ali H, Ghadbeigi H, Hosseinzadeh F, Oliveira J, Mumtaz K (2019) Effect of pre-emptive in situ parameter modification on residual stress distributions within selective laser-melted Ti6Al4V components. Int J Adv Manuf Technol 103(9–12):4467–4479

Gupta MK, Singla AK, Ji H, Song Q, Liu Z, Cai W, Mia M, Khanna N, Krolczyk GM (2020) Impact of layer rotation on micro-structure, grain size, surface integrity and mechanical behaviour of SLM Al-Si-10Mg alloy. J Mater Res Technol 9(5):9506–9522

Xiong Z, Liu S, Li S, Shi Y, Yang Y, Misra R (2019) Role of melt pool boundary condition in determining the mechanical properties of selective laser melting AlSi10Mg alloy. Mater Sci Eng A 740:148–156

Khanna N, Mistry S, Rashid RR, Gupta MK (2019) Investigations on density and surface roughness characteristics during selective laser sintering of Invar-36 alloy. Mater Res Express 6(8):086541

Jiang H-Z, Li Z-Y, Feng T, Wu P-Y, Chen Q-S, Feng Y-L, Li S-W, Gao H, Xu H-J (2019) Factor analysis of selective laser melting process parameters with normalised quantities and Taguchi method. Opt Laser Technol 119:105592

Alghamdi A, Downing D, McMillan M, Brandt M, Qian M, Leary M (2019) Experimental and numerical assessment of surface roughness for Ti6Al4V lattice elements in selective laser melting. Int J Adv Manuf Technol 105(1–4):1275–1293

Cho J, Xu W, Brandt M, Qian M (2019) Selective laser melting-fabricated Ti-6Al-4V alloy: microstructural inhomogeneity, consequent variations in elastic modulus and implications. Opt Laser Technol 111:664–670

Sun J, Yang Y, Wang D (2013) Parametric optimization of selective laser melting for forming Ti6Al4V samples by Taguchi method. Opt Laser Technol 49:118–124

Wang Z, Xiao Z, Tse Y, Huang C, Zhang W (2019) Optimization of processing parameters and establishment of a relationship between microstructure and mechanical properties of SLM titanium alloy. Opt Laser Technol 112:159–167

Cheng B, Lydon J, Cooper K, Cole V, Northrop P, Chou K (2018) Melt pool sensing and size analysis in laser powder-bed metal additive manufacturing. J Manuf Process 32:744–753

Liu J, Sun Q, Wang X, Li H, Guo K, Sun J (2019) Achieving Ti6Al4V alloys with both high strength and ductility via selective laser melting. Mater Sci Eng A 766:138319

Kusuma C, Ahmed SH, Mian A, Srinivasan R (2017) Effect of laser power and scan speed on melt pool characteristics of commercially pure titanium (CP-Ti). J Mater Eng Perform 26(7):3560–3568

Ghosh S, Ma L, Levine LE, Ricker RE, Stoudt MR, Heigel JC, Guyer JE (2018) Single-track melt-pool measurements and microstructures in Inconel 625. Jom 70(6):1011–1016

Großmann A, Felger J, Frölich T, Gosmann J, Mittelstedt C (2019) Melt pool controlled laser powder bed fusion for customised low-density lattice structures. Mater Des 181:108054

Furumoto T, Egashira K, Munekage K, Abe S (2018) Experimental investigation of melt pool behaviour during selective laser melting by high speed imaging. CIRP Ann 67(1):253–256

Yadroitsev I, Gusarov A, Yadroitsava I, Smurov I (2010) Single track formation in selective laser melting of metal powders. J Mater Process Technol 210(12):1624–1631

Liu J, Song Y, Chen C, Wang X, Li H, Wang J, Guo K, Sun J (2020) Effect of scanning speed on the microstructure and mechanical behavior of 316L stainless steel fabricated by selective laser melting. Mater Des 186:108355

Luo Z, Zhao Y (2019) Numerical simulation of part-level temperature fields during selective laser melting of stainless steel 316L. Int J Adv Manuf Technol 104(5–8):1615–1635

Tao W, Lingchao Q, Jiaqi L (2019) Parameter analysis of thermal behavior during laser melting of Ti-6Al-4V alloy powder. Int J Adv Manuf Technol 104(5–8):2875–2885

Heeling T, Cloots M, Wegener K (2017) Melt pool simulation for the evaluation of process parameters in selective laser melting. Addit Manuf 14:116–125

Liu Y, Zhang J, Pang Z (2018) Numerical and experimental investigation into the subsequent thermal cycling during selective laser melting of multi-layer 316L stainless steel. Opt Laser Technol 98:23–32

Liu S, Zhu J, Zhu H, Yin J, Chen C, Zeng X (2020) Effect of the track length and track number on the evolution of the molten pool characteristics of SLMed Al alloy: numerical and experimental study. Opt Laser Technol 123:105924

Masoomi M, Thompson SM, Shamsaei N (2017) Laser powder bed fusion of Ti-6Al-4 V parts: thermal modeling and mechanical implications. Int J Mach Tools Manuf 118–119:73–90

Zhang D, Zhang P, Liu Z, Feng Z, Wang C, Guo Y (2018) Thermofluid field of molten pool and its effects during selective laser melting (SLM) of Inconel 718 alloy. Addit Manuf 21:567–578

Li Z, Xu R, Zhang Z, Kucukkoc I (2018) The influence of scan length on fabricating thin-walled components in selective laser melting. Int J Mach Tools Manuf 126:1–12

Zhuang J-R, Lee Y-T, Hsieh W-H, Yang A-S (2018) Determination of melt pool dimensions using DOE-FEM and RSM with process window during SLM of Ti6Al4V powder. Opt Laser Technol 103:59–76

Foroozmehr A, Badrossamay M, Foroozmehr E, Si G (2016) Finite element simulation of selective laser melting process considering optical penetration depth of laser in powder bed. Mater Des 89:255–263

Zavala-Arredondo M, Ali H, Groom KM, Mumtaz K (2018) Investigating the melt pool properties and thermal effects of multi-laser diode area melting. Int J Adv Manuf Technol 97(1–4):1383–1396

Majeed M, Khan H, Rasheed I (2019) Finite element analysis of melt pool thermal characteristics with passing laser in SLM process. Optik 194:163068

Dong Z, Liu Y, Wen W, Ge J, Liang J (2019) Effect of hatch spacing on melt Pool and as-built quality during selective laser melting of stainless steel: modeling and experimental approaches. Materials 12(1):50

Li J, Wei Z, Yang L, Zhou B, Wu Y, Chen S-G, Sun Z (2020) Finite element analysis of thermal behavior and experimental investigation of Ti6Al4V in selective laser melting. Optik 207:163760

Huang W, Zhang Y (2019) Finite element simulation of thermal behavior in single-track multiple-layers thin wall without-support during selective laser melting. J Manuf Process 42:139–148

Liu J, Bolot R, Costil S, Planche M-P (2016) Transient thermal and mechanical analysis of NiCrBSi coatings manufactured by hybrid plasma spray process with in-situ laser remelting. Surf Coat Technol 292:132–143

Loh L-E, Chua C-K, Yeong W-Y, Song J, Mapar M, Sing S-L, Liu Z-H, Zhang D-Q (2015) Numerical investigation and an effective modelling on the selective laser melting (SLM) process with aluminium alloy 6061. Int J Heat Mass Transf 80:288–300

Safdar S, Pinkerton AJ, Li L, Sheikh MA, Withers PJ (2013) An anisotropic enhanced thermal conductivity approach for modelling laser melt pools for Ni-base super alloys. Appl Math Model 37(3):1187–1195

Ali H, Ghadbeigi H, Mumtaz K (2018) Residual stress development in selective laser-melted Ti6Al4V: a parametric thermal modelling approach. Int J Adv Manuf Technol 97(5–8):2621–2633

Tawfik SM, Nasr MNA, El Gamal HA (2019) Finite element modelling for part distortion calculation in selective laser melting. Alex Eng J 58(1):67–74

Li Y, Zhou K, Tan P, Tor SB, Chua CK, Leong KF (2018) Modeling temperature and residual stress fields in selective laser melting. Int J Mech Sci 136:24–35

Bian P, Shi J, Shao X, Du J (2019) Evolution of cyclic thermal stress in selective laser melting of 316L stainless steel: a realistic numerical study with experimental verification. Int J Adv Manuf Technol 104(9–12):3867–3882

Chen C, Yin J, Zhu H, Xiao Z, Zhang L, Zeng X (2019) Effect of overlap rate and pattern on residual stress in selective laser melting. Int J Mach Tools Manuf 145:103433

Chen C, Yin J, Zhu H, Zeng X, Wang G, Ke L, Zhu J, Chang S (2019) The effect of process parameters on the residual stress of selective laser melted Inconel 718 thin-walled part. Rapid Prototyp J 25(8):1359–1369

Gusarov A, Yadroitsev I, Bertrand P, Smurov I (2007) Heat transfer modelling and stability analysis of selective laser melting. Appl Surf Sci 254(4):975–979

Gusarov A, Yadroitsev I, Bertrand P, Smurov I (2009) Model of radiation and heat transfer in laser-powder interaction zone at selective laser melting. J Heat Transf 131(7):072101

Funding

The authors receive financial support from the National Natural Science Foundation of China (NSFC, Grant Nos.: 51905306 and 51975335), the Key Research and Development Program of Shandong Province (Grant Nos.: 2019GGX104008 and 2019GGX104006), Special Support for Post-doc Creative Funding of Shandong Province (201902005), and the Taishan Scholars Project of Shandong Province of China (No. ts20190975).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Waqar, S., Sun, Q., Liu, J. et al. Numerical investigation of thermal behavior and melt pool morphology in multi-track multi-layer selective laser melting of the 316L steel. Int J Adv Manuf Technol 112, 879–895 (2021). https://doi.org/10.1007/s00170-020-06360-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06360-0