Abstract

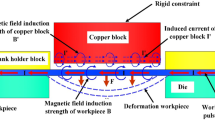

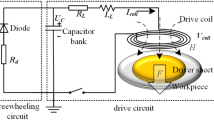

In the conventional electromagnetic forming processes, the Lorentz force is induced by the eddy current in the specimen, so the coil should be specifically designed to form the electrical current return. Here, a novel electromagnetic forming method is suggested for aluminum alloy strip or profile, in which the inverse current is imposed instead of eddy current to generate Lorentz force. As an electromagnetic actuator, a very simple strip of copper was connected in parallel with the aluminum alloy strip. When the impulse currents flowed synchronously along the opposite directions between the copper and aluminum alloy strips, the Lorentz force was generated to deform the aluminum alloy strip. The electromagnetic forming of AA5754 aluminum alloy strip by imposing inverse current was investigated by numerical simulation. It was finally validated by comparison with the experimental results.

Similar content being viewed by others

References

Psyk V, Risch D, Kinsey BL, Tekkaya AE, Kleiner M (2011) Electromagnetic forming-a review. J Mater Process Technol 211:787–829

Li J, Li L, Wan M, Yu H (2018) Innovation applications of electromagnetic forming and its fundamental problems, 17th International Conference on Metal Forming, Metal Forming 2018, 16-19, Toyohashi, Japan

Kamal M, Daehn G (2007) A uniform pressure electromagnetic actuator for forming flat sheets. J Manuf Sci Eng 129:369–379

Jiang H, Li N, Xu Z, Fan Z, Yu H, Liu L (2015) Microstructure, texture and mechanical properties of 5A02 aluminum alloy tubes under electromagnetic bulging. Mater Des 82:106–113

Li J, Qiu W, Huang L, Su H, Tao H, Li P (2018) Gradient electromagnetic forming (GEMF): a new forming approach for variable-diameter tubes by use of sectional coil. Int J Mach Tools Manuf 135:65–77

Xiong Q, Tang H, Wang M, Huang H, Qiu L, Yu K, Chen Q (2019) Design and implementation of tube bulging by an attractive electromagnetic force. J Mater Process Technol 273:116240

Yu H, Chen J, Liu W, Yin H, Li C (2018) Electromagnetic forming of aluminum circular tubes into square tubes: experiment and numerical simulation. J Manuf Process 31:613–623

Su H, Huang L, Li J, Ma F, Huang P, Feng F (2018) Two-step electromagnetic forming: a new forming approach to local features of large-size sheet metal parts. Int J Mach Tools Manuf 124:99–116

Liu W, Zou X, Huang S, Lei Y (2019) Electromagnetic-assisted calibration for surface part of aluminum alloy with a dedicated uniform pressure coil. Int J Adv Manuf Technol 100:721–727

Yu H, Jin Y, Hu L, Yin H, Sun S (2020) Two-step method to improve geometry accuracy of elongated hole flanging by electromagnetic forming. Int J Adv Manuf Technol 106:3117–3129

Paese E, Geier M, Homrich R, Rosa P, Rossi R (2019) Sheet metal electromagnetic forming using a flat spiral coil: experiments, modeling, and validation. J Mater Process Technol 263:408–422

Li N, Yu H, Xu Z, Fan Z, Liu L (2016) Electromagnetic forming facilitates the transition of deformation mechanism in 5052 aluminum alloy. Mater Sci Eng A 673:222–232

Okoye CN, Jiang JH, Hu ZD (2006) Application of electromagnetic-assisted stamping (EMAS) technique in incremental sheet metal forming. Int J Mach Tool Manu 46:1248–1252

Choi MK, Huh H, Park N (2017) Process design of combined deep drawing and electromagnetic sharp edge forming of DP980 steel sheet. J Mater Process Technol 244:331–343

Batygina YV, Golovashchenko SF, Gnatova AV (2013) Pulsed electromagnetic attraction of sheet metals – fundamentals and perspective applications. J Mater Process Technol 213:444–452

Noh HG, Song WJ, Kang BS, Kim J (2015) Two-step electromagnetic forming process using spiral forming coils to deform sheet metal in a middle-block die. Int J Adv Manuf Technol 76:1691–1703

Cui X, Mo J, Li J, Zhao J, Zhu Y, Huang L, Li Z, Zhong K (2014) Electromagnetic incremental forming (EMIF): a novel aluminum alloy sheet and tube forming technology. J Mater Process Technol 214:409–427

Su H, Huang L, Li J, Zhang Q, Liu X, Ma F (2020) On the forming uniformity during a single layer forming of electromagnetic incremental forming. Int J Adv Manuf Technol 107:4561–4572

Long A, Wan M, Wang W, Wu X, Cui X, Ma B (2018) Forming methodology and mechanism of a novel sheet metal forming technology - electromagnetic superposed forming (EMSF). Int J Solids Struct 151:165–180

Cui X, Zhang Z, Du Z, Yu H, Qiu D, Cheng Y, Xiao X (2020) Inverse bending and springback-control using magnetic pulse forming. J Mater Process Technol 275:116374

Xu J, Huang L, Hong X, Liu X, Su H, Ma F, Li J (2020) Research on the electromagnetic blanking based on force-free region deformation: simulation and experiments. Int J Adv Manuf Technol 108:1751–1766

Funding

This project was supported by National Natural Science Foundation of China (Grant No. 52005374) and Natural Science Foundation of Hubei Province (Grant No. 2019CFB196). We also would like to express our appreciation for the financial support from the State Key Laboratory of Materials Processing and Die and Mould Technology (Grant No. P2018-013, Huazhong University of Science and Technology, China) and the Jiangsu Key Laboratory of Precision and Micro-manufacturing Technology (Nanjing University of Aeronautics and Astronautics, China).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zeng, X., Meng, Z., Liu, W. et al. Electromagnetic forming of aluminum alloy strip by imposing inverse current instead of inducing eddy current. Int J Adv Manuf Technol 111, 3481–3488 (2020). https://doi.org/10.1007/s00170-020-06356-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06356-w