Abstract

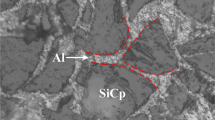

This work provides an in-depth investigation of the influence of laser energy density on the mechanical, surface, and dimensional properties of carbon fiber-reinforced PA12 parts manufactured by selective laser sintering (SLS). A space-filling design of experiments (DOE) was used to conduct the experimental trials to cover a wide range of laser sintering parameters. The consolidation mechanism was evaluated by microstructural and crystallization evolution of the samples produced at different energy densities, supported by mechanical testing, scanning electron microscopy (SEM), X-ray diffraction (XRD), and infrared spectroscopy (FTIR). Surface morphology was evaluated by profile measurements and SEM images. Laser sintering parameters had a significant influence on physical and mechanical properties, exhibiting complex and nonlinear behavior. Low energy density resulted in better dimensional accuracy, whereas intermediate laser energy resulted in the best mechanical properties. A trade-off could be seen when mechanical or dimensional properties were desired, and optimum energy values were strongly dependent on the criteria desired. All samples exhibited a brittle fracture behavior, with little plastic deformation present. Fracture mechanism occurred in the interlayer region or interface between carbon fiber and PA12, depending on the energy density applied. XRD analysis revealed a decrease in crystal fraction with increasing energy density. FTIR measurement suggested that polymer degradation at high energy densities could be present by both polymer chain scission and oxygen functional group decomposition and gas release upon laser heating of carbon fiber, resulting in lower mechanical properties.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Kruth JP, Wang X, Laoui T, Froyen L (2003) Lasers and materials in selective laser sintering. Assem Autom 23:357–371. https://doi.org/10.1108/01445150310698652

ASTM Standard F2792-12a (2012) Standard terminology for additive manufacturing technologies. West Conshohocken, PA

Kruth J-P, Mercelis P, Vaerenbergh J van, Froyen L and Rombouts M (2005) Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp J 11:26–36. https://doi.org/10.1108/13552540510573365

Wang X, Jiang M, Zhou Z, Gou J, Hui D (2017) 3D printing of polymer matrix composites: a review and prospective. Compos Part B 110:442–458. https://doi.org/10.1016/J.COMPOSITESB.2016.11.034

Goodridge RD, Tuck CJ, Hague RJM (2012) Laser sintering of polyamides and other polymers. Prog Mater Sci 57:229–267. https://doi.org/10.1016/j.pmatsci.2011.04.001

Kumar S, Kruth JP (2010) Composites by rapid prototyping technology. Mater Des 31:850–856. https://doi.org/10.1016/j.matdes.2009.07.045

Parandoush P, Lin D (2017) A review on additive manufacturing of polymer-fiber composites. Compos Struct 182:36–53. https://doi.org/10.1016/J.COMPSTRUCT.2017.08.088

Mazzoli A, Moriconi G, Pauri MG (2007) Characterization of an aluminum-filled polyamide powder for applications in selective laser sintering. Mater Des 28:993–1000. https://doi.org/10.1016/j.matdes.2005.11.021

Hon KKB, Gill TJ (2003) Selective laser sintering of SiC/polyamide composites. CIRP Ann Manuf Technol 52:173–176. https://doi.org/10.1016/S0007-8506(07)60558-7

Guo Y, Jiang K, Bourell DL (2014) Preparation and laser sintering of limestone PA 12 composite. Polym Test 37:210–215. https://doi.org/10.1016/j.polymertesting.2014.06.002

Negi S, Dhiman S, Sharma RK (2015) Determining the effect of sintering conditions on mechanical properties of laser sintered glass filled polyamide parts using RSM. Measurement 68:205–218. https://doi.org/10.1016/j.measurement.2015.02.057

Jain PK, Pandey PM, Rao PVM (2009) Selective laser sintering of clay-reinforced polyamide. Polym Compos 31:732–743. https://doi.org/10.1002/pc.20854

Athreya SR, Kalaitzidou K, Das S (2010) Processing and characterization of a carbon black-filled electrically conductive Nylon-12 nanocomposite produced by selective laser sintering. Mater Sci Eng A 527:2637–2642. https://doi.org/10.1016/j.msea.2009.12.028

Goodridge RD, Shofner ML, Hague RJM, McClelland M, Schlea MR, Johnson RB, Tuck CJ (2011) Processing of a polyamide-12/carbon nanofibre composite by laser sintering. Polym Test 30:94–100. https://doi.org/10.1016/j.polymertesting.2010.10.011

Bai J, Goodridge RD, Hague RJM, Song M (2013) Improving the mechanical properties of laser-sintered polyamide 12 through incorporation of carbon nanotubes. Polym Eng Sci 53:1937–1946. https://doi.org/10.1002/pen.23459

Salmoria GV, Paggi RA, Lago A, Beal VE (2011) Microstructural and mechanical characterization of PA12/MWCNTs nanocomposite manufactured by selective laser sintering. Polym Test 30:611–615. https://doi.org/10.1016/j.polymertesting.2011.04.007

Yang J, Shi Y, Yan C (2010) Selective laser sintering of polyamide 12/potassium titanium whisker composites. J Appl Polym Sci 117:2196–2204. https://doi.org/10.1002/app.31965

Yan C, Hao L, Xu L, Shi Y (2011) Preparation, characterisation and processing of carbon fibre/polyamide-12 composites for selective laser sintering. Compos Sci Technol 71:1834–1841. https://doi.org/10.1016/j.compscitech.2011.08.013

Jing W, Hui C, Qiong W, Hongbo L, Zhanjun L (2017) Surface modification of carbon fibers and the selective laser sintering of modified carbon fiber/nylon 12 composite powder. Mater Des 116:253–260. https://doi.org/10.1016/j.matdes.2016.12.037

Jansson A, Pejryd L (2016) Characterisation of carbon fibre-reinforced polyamide manufactured by selective laser sintering. Addit Manuf 9:7–13. https://doi.org/10.1016/j.addma.2015.12.003

Liu Y, Zhu L, Zhou L, Li Y (2019) Microstructure and mechanical properties of reinforced polyamide 12 composites prepared by laser additive manufacturing. Rapid Prototyp J 25:1127–1134. https://doi.org/10.1108/RPJ-08-2018-0220

EOS (2020) Material Data Center. http://eos.materialdatacenter.com/eo/en. Accessed 9 Jan 2020

ASTM Standard D638-02a (2002) Standard test method for tensile properties of plastics. In: West Conshohocken

ASTM Standard D790-02 (2002) Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. West Conshohocken

Cavazzuti M (2013) Optimization methods: from theory to design. Springer-Verlag, Berlin Heidelberg

ASTM Standard D5947-11 (2012) Standard test methods for physical dimensions of solid plastics specimens

Laumer T, Stichel T, Nagulin K, Schmidt M (2016) Optical analysis of polymer powder materials for selective laser sintering. Polym Test 56:207–213. https://doi.org/10.1016/j.polymertesting.2016.10.010

Mattos NRD, Oliveira CRD, Camargo LGB, Silva RSRD, Lavall RL (2018) Azo dye adsorption on anthracite: a view of thermodynamics, kinetics and cosmotropic effects. Sep Purif Technol 209:806–814. https://doi.org/10.1016/j.seppur.2018.09.027

Herrin JM, Deming D (1996) Thermal conductivity of U.S. coals. J Geophys Res Solid Earth 101:25381–25386. https://doi.org/10.1029/96jb01884

Bai J, Goodridge RD, Yuan S, Zhou K, Chua CK, Wei J (2015) Thermal influence of CNT on the polyamide 12 nanocomposite for selective laser sintering. Molecules 20:19041–19050. https://doi.org/10.3390/molecules201019041

Guo J, Bai J, Liu K, Wei J (2018) Surface quality improvement of selective laser sintered polyamide 12 by precision grinding and magnetic field-assisted finishing. Mater Des 138:39–45. https://doi.org/10.1016/j.matdes.2017.10.048

Launhardt M, Wörz A, Loderer A, Laumer T, Drummer D, Hausotte T, Schmidt M (2016) Detecting surface roughness on SLS parts with various measuring techniques. Polym Test. https://doi.org/10.1016/j.polymertesting.2016.05.022

Anestiev L, Froyen L (1999) Model of the primary rearrangement processes at liquid phase sintering and selective laser sintering due to biparticle interactions. J Appl Phys 86:4008. https://doi.org/10.1063/1.371321

Kruth J-P, Levy G, Klocke F, Childs THC (2007) Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann Manuf Technol 56:730–759. https://doi.org/10.1016/j.cirp.2007.10.004

Dupin S, Lame O, Barrès C, Charmeau J-YY (2012) Microstructural origin of physical and mechanical properties of polyamide 12 processed by laser sintering. Eur Polym J 48:1611–1621. https://doi.org/10.1016/j.eurpolymj.2012.06.007

Jauffrès D, Lame O, Vigier G, Doré F, Douillard T (2009) Sintering mechanisms involved in high-velocity compaction of nascent semicrystalline polymer powders. Acta Mater 57:2550–2559. https://doi.org/10.1016/j.actamat.2009.02.012

Atkins EDT, Hill MJJ, Veluraja K (1995) Structural and morphological investigations of nylon 8 chain-folded lamellar crystals. Polymer 36:35–42. https://doi.org/10.1016/0032-3861(95)90672-O

Rhee S, White JL (2002) Crystal structure and morphology of biaxially oriented polyamide 12 films. J Polym Sci B Polym Phys 40:1189–1200. https://doi.org/10.1002/polb.10181

Zhang J, Adams A (2016) Understanding thermal aging of non-stabilized and stabilized polyamide 12 using 1H solid-state NMR. Polym Degrad Stab 134:169–178. https://doi.org/10.1016/j.polymdegradstab.2016.10.006

Celina M, Ottesen DK, Gillen KT, Clough RL (1997) FTIR emission spectroscopy applied to polymer degradation. Polym Degrad Stab 58:15–31. https://doi.org/10.1016/S0141-3910(96)00218-2

Acknowledgments

The authors would like to thank Financiadora de Estudos e Projetos (FINEP) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Czelusniak, T., Amorim, F.L. Influence of energy density on selective laser sintering of carbon fiber-reinforced PA12. Int J Adv Manuf Technol 111, 2361–2376 (2020). https://doi.org/10.1007/s00170-020-06261-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06261-2