Abstract

Cold rollings of A1008 steel specimens are carried out in this study to analyze the influences of roll’s surface pattern and specimen’s reduction ratio on surface morphologies, optical properties, and mechanical properties of rolled samples. A 3D fractal formula, along with dedicated algorithms developed, is applied to solve the periodic (characteristics) lengths and fractal dimensions for roll and rolled surfaces along and perpendicular to the rolling directions. The correlation for every fractal parameter between roll and the rolled specimen is developed to be a function of roll’s surface pattern and reduction ratio first. The light tracking simulations were then carried out for rolled samples only. Rockwell hardness and tensile tests were conducted to evaluate the specimen’s hardness and Young’s modulus. A roll having a higher fractal dimension, or a longer periodic length, can result in a higher fractal dimension and a longer periodic length of the rolled specimen, respectively. A larger reduction ratio also results in the rolled surface with higher fractal dimensions and longer periodic lengths. Increasing the fractal dimensions of a rolled specimen can elevate the maximum illuminance and, conversely, lower the minimum illuminance, while an increase in periodic lengths can increase the minimum illuminance and decrease the maximum illuminance. A decrease in the fractal dimensions and/or increase in the periodic lengths of rolled surfaces in the two directions can raise the illuminance uniformity. For the specimens prepared with the same roll pattern, an increase in reduction ratio can bring an increment in illuminance uniformity and hardness of rolled samples. This study provides an efficient way to determine the roll pattern and reduction ratio that satisfies the specific demands in optical properties.

Similar content being viewed by others

Abbreviations

- (Dx)R :

-

Roll fractal dimension parallel to the rolling direction

- (Dy)R :

-

Roll fractal dimension perpendicular to the rolling direction

- (Dx)S :

-

Specimen fractal dimension parallel to the rolling direction

- (Dy)S :

-

Specimen fractal dimension perpendicular to the rolling direction

- Ku :

-

Kurtosis

- (Lx)R :

-

Roll characteristic length parallel to the rolling direction

- (Ly)R :

-

Roll characteristic length perpendicular to the rolling direction

- (Lx)S :

-

Specimen characteristic length parallel to the rolling direction

- (Ly)S :

-

Specimen characteristic length perpendicular to the rolling direction

- l :

-

Length of interval for a periodic surface profile

- N :

-

Numeral value essential to accomplish lateral resolution

- N φ :

-

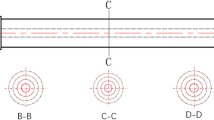

Parameter governing the orientation of grooving channels

- R r :

-

Reduction ratio of specimen

- R z :

-

Quantitative variances between the highest peak and lowest valley along the length l

- Sk :

-

Skewness

- U n :

-

Illuminance uniformity

- (IL)max :

-

Maximum illuminance

- (IL)min :

-

Minimum illuminance

- 3D:

-

Three-dimensional

- γ :

-

Gamma (spatial frequency density)

- \( \overline{\theta} \) :

-

Light incident angle

References

Total Materia - Steel Properties. https://www.totalmateria.com/page.aspx?ID=SteelProperties&LN=EN. Accessed 4 May 2020

Lenard JG (2004) The effect of roll roughness on the rolling parameters during cold rolling of an aluminum alloy. J Mater Process Technol 152:144–153. https://doi.org/10.1016/j.jmatprotec.2004.03.026

Kijima H (2014) Influence of roll radius on roughness transfer in skin-pass rolling of steel strip. J Mater Process Technol 214:1111–1119. https://doi.org/10.1016/j.jmatprotec.2013.12.019

Hedayati A, Najafizadeh A, Kermanpur A, Forouzan F (2010) The effect of cold rolling regime on microstructure and mechanical properties of AISI 304L stainless steel. J Mater Process Technol 210:1017–1022. https://doi.org/10.1016/j.jmatprotec.2010.02.010

Lin JF, Huang TK, Hsu CT (1991) Evaluation of lubricants for cold strip rolling. Wear 147:79–91. https://doi.org/10.1016/0043-1648(91)90120-J

Pawelski H (2004) Interaction between mechanics and tribology for cold rolling of strip with special emphasis on surface evolution. TU Bergakad, Freiberg

Wang J, Wu C, Liu C, Wei J (2015) Fractal Simulation on Random Rough Surface. In: International Conference on Automation, Mechanical Control and Computational Engineering. Atlantis Press, China, pp 2248–2252

Ausloos M, Berman DH (1985) A multivariate Weierstrass–Mandelbrot function. Proc R Soc Lond A Math Phys Sci 400:331–350. https://doi.org/10.1098/rspa.1985.0083

Majumdar A, Tien CL (1990) Fractal characterization and simulation of rough surfaces. Wear 136:313–327. https://doi.org/10.1016/0043-1648(90)90154-3

Mahmood MA, Tsai TY, Hwu YJ, Lin WJ, Liu LC, Lai JY, Pan JW, Li WL, Lin JF (2020) Effect of fractal parameters on optical properties of cold rolled aluminum alloy strips with induced surface deflection: simulations and experimental correlations. J Mater Process Technol 279:116554. https://doi.org/10.1016/j.jmatprotec.2019.116554

Sugino T, Yamane Y (2015) Gloss evaluation of hairline-finished metal surface using patterned area illumination method: reproduction of gloss evaluation by ray tracing. Key Eng Mater 656–657:468–472. https://doi.org/10.4028/www.scientific.net/KEM.656-657.468

Ohkabo T, Shibata K, Sato K, Seki K, Odaka Y (1997) Quantitative analysis for surface topography of aluminum foil by SEM and AFM. In: First International Conference on Tribology in Manufacturing Processes, Gifu, Japan, pp 59–64

Online Materials Information Resource - MatWeb. http://matweb.com/search/datasheet. aspx?MatGUID=145867c159894 de286d4803a0fc0fe0f&ckck=1. Accessed 4 May 2020

Nippon Roll MFG.Co.,Ltd.|Company Profile. http://www.nippon-roll.co.jp/nihonroll/nr/honsya/kaishagaiyou-e.html. Accessed 4 May 2020

Yu YW, Chen YL, Chen WH, Chen HX, Lee XH, Lin CC, Sun CC (2012) Bidirectional scattering distribution function by screen imaging synthesis. Opt Express 20(101):A75–A84

Mandelbrot B (1967) How long is the coast of Britain? Statistical self-similarity and fractional dimension. Science (80- ) 156:636–638. https://doi.org/10.1126/science.156.3775.636

Gadelmawla ES (2011) Estimation of surface roughness for turning operations using image texture features. Proc Inst Mech Eng B J Eng Manuf 225:1281–1292. https://doi.org/10.1177/2041297510393643

de Boor C (2001) A practical guide to splines - Revised Edition

Perepezko JH, Imhoff SD, Chen MW, Wang JQ, Gonzalez S (2014) Nucleation of shear bands in amorphous alloys. Proc Natl Acad Sci U S A 111:3938–3942. https://doi.org/10.1073/pnas.1321518111

The Iron-Iron Carbide (Fe-Fe 3 C) Phase diagram

AISI 1008 Carbon Steel (UNS G10080) (2012).

Acknowledgments

The authors would like to concede the kind assistance of China Steel Corporation, Kaohsiung, Taiwan, ROC, in performing cold-rolling experiments.

Funding

M.A.M., has received funds from the European Union’s Horizon 2020 (H2020) research and innovation program, under the Marie Skłodowska-Curie grant agreement no. 764935. I.N.M., acknowledges with thanks the partial financial support of this work under the POC-G Contract no. 135/2016. Further, this study was supported by a research funding provided under agreement no. 107-2221-E-006-092 between National the Cheng Kung University (NCKU) and the Ministry of Science and Technology (MOST) Taiwan, ROC, to carry out experimental work at Micro/Nano Tribology Laboratory, NCKU.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahmood, M.A., Han, CF., Chu, HY. et al. Effects of roll pattern and reduction ratio on optical characteristics of A1008 cold–rolled steel specimens: analytical approach and experimental correlations. Int J Adv Manuf Technol 111, 2001–2020 (2020). https://doi.org/10.1007/s00170-020-06191-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06191-z