Abstract

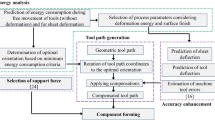

Incremental Sheet Forming (ISF) is a dieless forming process and has capability to form complex 3D geometries. Double Sided Incremental Forming (DSIF) is the most flexible variant of ISF as it uses two tools, one on either side of the sheet (one tool forms the sheet and other acts as support). However, forming the components with acceptable accuracy is one of the challenges as it depends on many factors such as sheet and tool(s) deflections as well as machine tool errors. If these deflections/deviations are not compensated in tool path, accuracy of the component gets affected and support tool may lose contact or squeeze the sheet while forming components. In the present work, grid-based method is used to measure the machine tool error at discrete points of the work envelope. To enhance the accuracy and support tool contact condition, machine tool errors are compensated in tool path along with tool and sheet deflection compensations developed earlier. To demonstrate the effectiveness of developed methodology on the accuracy, components having different geometric characteristics as well as opening sizes are formed with and without compensating for machine tool errors in tool path. Results indicate that deviation in symmetry within the same contour reduced from 850 μm to less than 40 μm. In addition, support tool has maintained contact throughout support surface with maximum force of 50 N when machine tool errors are compensated.

Similar content being viewed by others

References

Cao J, Huang Y, Reddy NV, Malhotra R, Wang Y (2008) Incremental sheet metal forming: advances and challenges. In: Proceedings of ICTP international Conference on Technology of Plasticity, Gyeongju, pp 751–752

Jeswiet J, Micari F, Hirt G, Bramley A, Duflou J, Allwood J (2005) Asymmetric single point incremental forming of sheet metal. CIRP Annals Manuf Technol 54(2):88–114

Reddy NV, Lingam R (2018) Double sided incremental forming: capabilities and challenges. J Phys Conf Ser 1063:1–6

Lu H, Liu H, Wang C (2019) Review on strategies for geometric accuracy improvement in incremental sheet forming. Int J Adv Manuf Technol 102(9–12):3381–3417

Peng W, Ou H, Becker A (2019) Double-sided incremental forming: a review. ASME J Manuf Sci Eng 141(5):050802 (1–12)

Hirt G, Junk S, Bambach M, Chouvalova I (2003) Process limits and material behaviour in incremental sheet forming with CNC-tools. Mater Sci Forum 426-432:3825–3830

Duflou JR, Callebaut B, Verbert J, De Baerdemaeker H (2007) Laser assisted incremental forming: formability and accuracy improvement. CIRP Annals Manuf Technol 56(1):273–276

Duflou JR, Callebaut B, Verbert J, De Baerdemaeker H (2008) Improved SPIF performance through dynamic local heating. Int J Mach Tools Manuf 48(5):543–549

Allwood JM, Music O, Raithathna A, Duncan SR (2009) Closed-loop feedback control of product properties in flexible metal forming processes with mobile tools. CIRP Annals Manuf Technol 58(1):287–290

Belchior J, Guillo M, Courteille E, Maurine P, Leotoing L, Guines D (2013) Off-line compensation of the tool path deviations on robotic machining: application to incremental sheet forming. Robot Comput Integr Manuf 29(4):58–69

Verbert J, Aerens R, Vanhove H, Aertbeliën E, Duflou JR (2009) Obtainable accuracies and compensation strategies for robot supported SPIF. Key Eng Mater 410–411:679–687

Asghar J, Lingam R, Shibin E, Reddy NV (2014) Tool path design for enhancement of accuracy in single-point incremental forming. Proc Inst Mech Eng Part B J Eng Manuf 228(9):1027–1035

Meier H, Smukala V, Dewald O, Zhang J (2007) Two point incremental forming with two moving forming tools. Key Eng Mater 344:599–605

Meier H, Buff B, Laurischkat R, Smukala V (2009) Increasing the part accuracy in dieless robot-based incremental sheet metal forming. CIRP Annals Manuf Technol 58(1):233–238

Meier H, Magnus C, Smukal V (2011) Impact of superimposed pressure on dieless incremental sheet metal forming with two moving tools. CIRP Annals Manuf Technol 60(1):327–330

Malhotra R, Cao J, Ren F, Kiridena V, Cedric Xia Z, Reddy NV (2011) Improvement of geometric accuracy in incremental forming by using a squeezing toolpath strategy with two forming tools. ASME J Manuf Sci Eng 133(6):061019(1–10)

Ren H, Xie J, Liao S, Leem D, Ehmann K, Cao J (2019) In-situ springback compensation in incremental sheet forming. CIRP Annals Manuf Technol 68(1):317–320

Lingam R, Amit S, Reddy NV (2016) Deflection compensations for tool path to enhance accuracy during double-sided incremental forming. ASME J Manuf Sci Eng 138(9):091008 (1–11)

Konka P, Lingam R, Reddy NV (2020) Tool path design system to enhance accuracy during double sided incremental forming: an analytical model to predict compensations for small/large components. J Manuf process 58:510–523

Xu R, Ren H, Zhang Z, Malhotra R, Cao J (2014) A Mixed toolpath strategy for improved geometric accuracy and higher throughput in double-sided incremental forming. In: ASME 2014 international manufacturing science and engineering conference collocated with the JSME 2014 international conference on materials and processing and the 42nd North American manufacturing research conference, pp V002T02A082–V002T02A082

Zhang Z, Ren H, Xu R, Moser N, Smith J, Ndip-Agbor E, Malhotra R, Xia ZC, Ehmann KF, Cao J (2015) A mixed double-sided incremental forming toolpath strategy for improved geometric accuracy. ASME J Manuf Sci Eng 137(5): 051007 (1–7)

Ren H, Moser N, Cao J (2016) Simulation and analysis of double-sided incremental forming considering machine compliance. Proceedings of 12th international Conference on Numerical Methods in Industrial Forming Process 1–3

Moser N, Zhang Z, Ren H, Zhang H, Shi Y, Ndip-Agbor E, Lu B, Chen J, Ehmann KF, Cao J (2016) Effective forming strategy for double-sided incremental forming considering in-plane curvature and tool direction. CIRP Annals Manuf Technol 65(1):265–268

Ren H, Li F, Moser N, Leem D, Li T, Ehmann K, Cao J (2018) General contact force control algorithm in double-sided incremental forming. CIRP Annals Manuf Technol 67(1):381–384

Leem D, Moser N, Ren H, Mozaffar M, Ehmann KF, Cao J (2019) Improving the accuracy of double-sided incremental forming simulations by considering kinematic hardening and machine compliance. Procedia Manuf 29:88–95

Lingam R, Prakash O, Belk JH, Reddy NV (2017) Automatic feature recognition and tool path strategies for enhancing accuracy in double sided incremental forming. Int J Adv Manuf Technol 88(5–8):1639–1655

Schwenke H, Knapp W, Haitjema H, Weckenmann A, Schmitt R, Delbressine F (2008) Geometric error measurement and compensation of machines-an update. CIRP Annals Manuf Technol 57(2):660–675

Timoshenko SP, Woinowsky-Krieger S (1959) Theory of plates and shells. McGraw Hill Education, NewYork

Yoshikawa T, Nakamura K, Ueno K, Shima A (1999) Study on incremental sheet metal bulging using tool bar. Japanese Spring Conference on Technology of Plasticity 305

Tanaka S, Nakamura T, Hayakawa K, Nakamura H, Motomura K (2007) Residual stress in sheet metal parts made by incremental forming process. AIP Conference Proceedings 908(1):775–780

Radu C, Herghelegiu E, Tampu C, Cristea I (2013) The residual stress state generated by single point incremental forming of aluminum metal sheets. Appl Mech Mater 371:148–152

Adabala S, Lingam R, Hayakawa K, Tanaka S, Reddy NV (2019) Experimental and numerical investigation of residual stresses in incremental forming. Mater Trans 61(2):228–233

Bhattacharya A, Maneesh K, Reddy NV, Cao J 2011 Formability and surface finish studies in single point incremental forming. ASME J Manuf Sci Eng 133(6): 061020(1–8)

Filice L, Fratini L, Micari F (2002) Analysis of material formability in incremental forming. CIRP Annals Manuf Technol 51(1):199–202

Silva M, Skjødt M, Martins PA, Bay N (2008) Revisiting the fundamentals of single point incremental forming by means of membrane analysis. Int J Mach Tools Manuf 48(1):73–83

Bansal A, Lingam R, Yadav SK, Reddy NV (2017) Prediction of forming forces in single point incremental forming. J Manuf Process 28(3):486–493

Acknowledgments

This work is supported by SERB, Department of Science and Technology, New Delhi, India (Sanction no. EMR/2015/ 000286).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Konka, P., Lingam, R., Singh, U.A. et al. Enhancement of accuracy in double sided incremental forming by compensating tool path for machine tool errors. Int J Adv Manuf Technol 111, 1187–1199 (2020). https://doi.org/10.1007/s00170-020-06149-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06149-1