Abstract

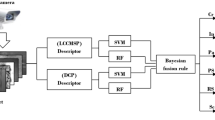

In steel-making processes, different methods are used for online surface product monitoring. Such a control has become a necessity to avoid additional costs resulting from the poor quality of the final product. With the reported performance that varies from one application to another, all the applied methods have to meet a minimum of criteria as accuracy and speed. This effectiveness is assured thanks to a relevant image description and efficient defect classification algorithms. The Dual Cross Pattern technique, successfully applied in face recognition, is a concept that relies on coding pixels to provide such a discriminating description of the image. Its principle can perfectly be used in industrial vision applications for surface defect recognition. In this study, the relevance of this method of describing defect images is evaluated, and improvements are proposed to increase its efficiency. The experimental study shows that the pixel coding that considers the variations of the intensity in several directions and captures the information from more than one pixel-neighborhood level makes it possible to better detect the variability in the defect image and helps to increase the defect recognition rate. The experiments are carried out with the use of the published Northeastern University (NEU) database for the comparison and with a new constructed database to better show the improvements brought by the proposed approach.

Similar content being viewed by others

References

Xie X (2008) A review of recent advances in surface defect detection using texture analysis techniques. Electron Lett Comput Vision Image Anal 7(3):1–22. Published by Computer Vision Center/Universitat Autonoma de Barcelona, Barcelona, Spain

Choi SH, Yun JP, Seo B, Park Y, Kim SW (2007) Real-time defects detection algorithm for high-speed steel bar in coil, world academy of science. Eng Technol 25:66–70

Blackledge JM, Dubovitskiy DA (2008) A surface inspection machine vision system that includes fractal texture analysis, international society for advanced science and technology. J Intell Syst 3(2):76–89

Ghorai S, Mukherjee A, Gangadaran M, Dutta PK (2013) Automatic defect detection on hot-rolled flat steel products. IEEE Transa Instrum Meas 62(3):612–621

Xiu-yong W, Ke X, Jin-wu X (2008) Application of undecimated wavelet transform to surface defect detection of hot rolled steel plates. IEEE Congr Image Sign Process 528–532. https://doi.org/10.1109/CISP.2008.278

Choi DC, Jeon YJ, Yun JP, Yun SW, Kim SW (2012) An algorithm for detecting seam cracks in steel plates. World Acad Sci Eng Technol Int J Mech Aerosp Ind Mechatron Manuf Eng 6(12):2835–2838

Jeon YJ, Choi D-C, Yun JP, Park C, Kim SW (2011) Detection of scratch defects on slab surface. Proceedings of the 11th International Conference on Control, Automation and Systems (ICCAS '11), 1274–1278, Gyeonggi-do, South Korea, October 2011

Yazdchi MR, Mahyari AG, Nazeri A Detection and classification of surface defects of cold rolling mill steel using morphology and neural network, pp. 1071–1076. IEEE CIMCA 2008, IAWTIC 2008, and ISE 2008

Mentouri Z, Moussaoui A, Boudjehem D, Doghmane H (2018) Steel strip surface defect identification based on binarized statistical features. Sci Bullet Ser B: Chem Mater Sci 80(4) ISSN 1454-2331, U.P.B Romania

Djukic D, Spuzic S (2007) Statistical discriminator of surface defects on hot rolled steel (Proceedings of Image and Vision Computing). University of Waikato, Hamilton, pp 158–163

Song K, Yan Y (2013) A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl Surf Sci 285P:858–864. Available at: https://doi.org/10.1016/j.apsusc.2013.09.002

Maoxiang CHU, Rongfen GONG (2015) Invariant feature extraction method based on smoothed local binary pattern for strip steel surface defect. ISIJ Int 55(9):1956–1962

Maenpaa T (2006) Surface Quality Assessment with advanced texture analysis techniques. Proc. of International Surface Inspection Summit, Luxembourg

Ojala T, Pietikäinen M (2002) Senior Member, IEEE, and Topi MäÈenpää, Multiresolution gray-scale and rotation invariant texture classification with local binary patterns. IEEE Trans Pattern Anal Mach Intell 24(7):971–987. https://doi.org/10.1109/TPAMI.2002.1017623

Xiao M, Jiang M, Li G, Xie L, Yi L (2017) An evolutionary classifier for steel surface defects with small sample set EURASIP. J Image Video Process 2017:48. https://doi.org/10.1186/s13640-017-0197-y

Mentouri Z, Doghmane H, Moussaoui A, Boudjehem D. Surface flaw classification based on Dual Cross Pattern. 1st IEEE International Conference on Communications, Control Systems and Signal Processing. 16,17th March, 2020, El-Oued University, Algeria

Ding C, Choi J, Tao D, Davis LS (2016) Multi-directional multi-level dual-cross patterns for robust face recognition. IEEE Trans Pattern Anal Mach Intell 38(3):518–531

Song K, Hu S, Yan Y (2014) Automatic recognition of surface defects on hot-rolled steel strip using scattering convolution network. J Comput Inf Syst 10:7, 3049–3055

Yi L, Li G, Jiang M (2016) An end-to-end steel strip surface defects recognition system based on convolutional neural networks. Steel Res Int. 87(9999). https://doi.org/10.1002/srin.201600068. Available at: www.steel-research.de

Ashour MW, Khalid F, Abdul Halin A, Abdullah LN, Darwish SH (2018) Surface defects classification of hot-rolled steel strips using multi-directional shearlet features. Arab J Sci Eng. Springer. https://doi.org/10.1007/s13369-018-3329-5

Zhou F, Liu G, Xu F, Deng H (2019) A generic automated surface defect detection based on a bilinear model. Appl Sci 9:3159. https://doi.org/10.3390/app9153159

Neogi N, Mohanta DK, Dutta PK (2014) Review of vision-based steel surface inspection systems. EURASIP J Image Video Process. Available at: https://doi.org/10.1186/1687-5281-2014-50

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mentouri, Z., Doghmane, H., Moussaoui, A. et al. Improved cross pattern approach for steel surface defect recognition. Int J Adv Manuf Technol 110, 3091–3100 (2020). https://doi.org/10.1007/s00170-020-06050-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06050-x