Abstract

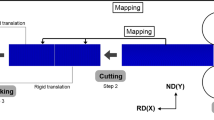

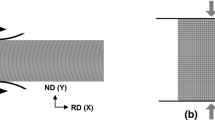

The deformation of accumulative roll-bonding (ARB) is complicated due to repeated cutting, stacking and roll-bonding. In this report, the deformation of multi-pass unidirectional and reverse rolling was first investigated, and then the investigation was extended to ARB. Aluminium single crystal {1 0 0}<0 0 1> (Cube) was chosen as the starting material, and crystal plasticity finite element method was used. The predictions after unidirectional and reverse rolling were validated by experimental observations. Macroscopic subdivision occurred by forming matrix bands through the thickness. It was found that the subdivision at the macroscopic scale was respectively amplified and destroyed after unidirectional rolling and reverse rolling. After ARB, macroscopic subdivision was partially amplified and destroyed through the thickness. Another modelling technique, Submodel, was adopted to highly increase the mesh resolution in selected smaller regions, by which micro-subdivision was successfully captured and verified by experimental results. Similar to the macro-subdivision, the micro-subdivision was respectively strengthened and disrupted after unidirectional rolling and reverse rolling. At both the macro- and micro-scale, the crystal rotation, slip activity and shear strain alternate their directions through the thickness, and the correlation between them three was investigated based on the crystal plasticity theory. Finally, the effect of rolling direction to texture, microstructure and mechanical properties was discussed.

Similar content being viewed by others

References

Huang X, Tsuji N, Hansen N, Minamino Y (2003) Microstructural evolution during accumulative roll-bonding of commercial purity aluminum. Mater Sci Eng A 340(1–2):265–271

Liu Q, Wert J, Hansen N (2000) Location-dependent lattice rotation and shear strain in rolled aluminum single crystals of cube and Goss orientations. Acta Mater 48(17):4267–4279

Van Houtte P et al (2005) Deformation texture prediction: from the Taylor model to the advanced Lamel model. Int J Plast 21(3):589–624

Roters F, Eisenlohr P, Hantcherli L, Tjahjanto DD, Bieler TR, Raabe D (2010) Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: theory, experiments, applications. Acta Mater 58(4):1152–1211

Roters F et al (2010) Crystal plasticity finite element methods: in materials science and engineering. Wiley-VCH

Pirgazi H, Akbarzadeh A, Petrov R, Sidor J, Kestens L (2008) Texture evolution of AA3003 aluminum alloy sheet produced by accumulative roll bonding. Mater Sci Eng A 492(1):110–117

Prakash A, Nöhring WG, Lebensohn RA, Höppel HW, Bitzek E (2015) A multiscale simulation framework of the accumulative roll bonding process accounting for texture evolution. Mater Sci Eng A 631:104–119

Wang H, Lu C, Tieu K, Deng G, Wei P, Liu Y (2019) A crystal plasticity FEM study of through-thickness deformation and texture in a {112} <111> aluminium single crystal during accumulative roll-bonding. Sci Rep 9(1):3401

Verstraete K, Helbert AL, Brisset F, Benoit A, Paillard P, Baudin T (2015) Microstructure, mechanical properties and texture of an AA6061/AA5754 composite fabricated by cross accumulative roll bonding. Mater Sci Eng A 640:235–242

Zhao Z, Kuchnicki S, Radovitzky R, Cuitiño A (2007) Influence of in-grain mesh resolution on the prediction of deformation textures in fcc polycrystals by crystal plasticity FEM. Acta Mater 55(7):2361–2373

Harewood FJ, McHugh PE (2006) Investigation of finite element mesh independence in rate dependent materials. Comput Mater Sci 37(4):442–453

ABAQUS, ABAQUS analysis user's guide (Version 6.9). Dassault Systems Simulia Corp.: Providence, RI, U.S.

Asaro RJ (1983) Crystal plasticity. J Appl Mech, Trans ASME 50(4 b):921–934

Asaro RJ, Needleman A (1985) Overview no. 42 texture development and strain hardening in rate dependent polycrystals. Acta Metall 33(6):923–953

Wu T-Y, Bassani JL, Laird C (1991) Latent hardening in single crystals I. Theory and experiments. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 435:20

Bassani JL, Wu T-Y (1991) Latent hardening in single crystals II. Analytical characterization and predictions. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 435:21

Wert JA, Liu Q, Hansen N (1997) Dislocation boundary formation in a cold-rolled cube-oriented Al single crystal. Acta Mater 45(6):2565–2576

Wert JA (2002) Macroscopic crystal rotation patterns in rolled aluminium single crystals. Acta Mater 50(12):3125–3139

Kamikawa N, Sakai T, Tsuji N (2007) Effect of redundant shear strain on microstructure and texture evolution during accumulative roll-bonding in ultralow carbon IF steel. Acta Mater 55(17):5873–5888

Raabe D, Zhao Z, Park SJ, Roters F (2002) Theory of orientation gradients in plastically strained crystals. Acta Mater 50(2):421–440

Paul H et al (2009) Deformation microstructure and texture evolution of {110}<112> Al-0.3wt.%Mn single crystals compressed in a channel-die. Arch Metall Mater 54(1):65–74

Liu Q, Hansen N (1998) Macroscopic and microscopic subdivision of a cold-rolled aluminium single crystal of cubic orientation. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 454(1978):2555–2591

Liu Q, Juul Jensen D, Hansen N (1998) Effect of grain orientation on deformation structure in cold-rolled polycrystalline aluminium. Acta Mater 46(16):5819–5838

Kashihara K, Inagaki H (2007) Rolling textures in aluminum single crystal deviated by 5 degrees about rolling direction from (001) [100] orientation. Mater Trans 48(8):1986–1991

Basson F, Driver JH (2000) Deformation banding mechanisms during plane strain compression of cube-oriented f.c.c. crystals. Acta Mater 48(9):2101–2115

Raabe D, Zhao Z, Mao W (2002) On the dependence of in-grain subdivision and deformation texture of aluminum on grain interaction. Acta Mater 50(17):4379–4394

Wang H, Lu C, Tieu AK, Su L, Deng G (2019) Coupled effects of initial orientation scatter and grain-interaction to texture evolution: a crystal plasticity FE study. Int J Mater Form 12(1):161–171

Yang HP, Sha YH, Zhang F, Zuo L (2010) Through-thickness shear strain control in cold rolled silicon steel by the coupling effect of roll gap geometry and friction. J Mater Process Technol 210(12):1545–1550

Lee CS, Duggan BJ (1991) Simple theory for the development of inhomogeneous rolling textures. Metallurgical transactions. A, Physical metallurgy and materials science 22 A(11):2637–2643

Chino Y, Sassa K, Kamiya A, Mabuchi M (2006) Influence of rolling routes on press formability of a rolled AZ31 Mg alloy sheet. Mater Trans 47(10):2555–2560

Higginson RL, Sellars CM (2002) The effect of strain path reversal during hot rolling on austenitic stainless steel. Mater Sci Eng A 338(1):323–330

Davenport SB, Higginson RL, Sellars CM (1999) The effect of strain path on material behaviour during hot rolling of FCC metals. Philos Trans R Soc A Math Phys Eng Sci 357(1756):1645–1661

Gurao NP, Sethuraman S, Suwas S (2011) Effect of strain path change on the evolution of texture and microstructure during rolling of copper and nickel. Mater Sci Eng A 528(25):7739–7750

Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1998) The process of grain refinement in equal-channel angular pressing. Acta Mater 46(9):3317–3331

Funding

This work was supported by Australian Research Council Discovery Project (Grant number: DP170103092).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 19 kb)

Rights and permissions

About this article

Cite this article

Wang, H., Lu, C. & Wang, R. A crystal plasticity FEM study on macro- and micro-subdivision of an aluminium single crystal after multi-pass unidirectional rolling, reverse rolling and accumulative roll-bonding. Int J Adv Manuf Technol 111, 37–51 (2020). https://doi.org/10.1007/s00170-020-06025-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06025-y