Abstract

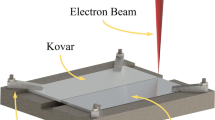

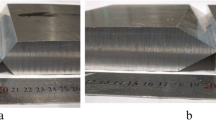

Electron beam butt welding of zircaloy-4 plates of dissimilar thickness (with different thickness ratio, defined as the thickness of one side plate with variable thickness to that of another reference plate of fixed thickness) was performed in order to investigate the effect of plate thickness on the evolution of cooling rate, microstructure and its correlation to mechanical properties. Faster cooling rate on thicker plate results in lower peak temperature, finer grain size both in fusion zone and heat-affected zone with more but uniform porosity distribution than those in the thinner plate. The size of HAZ was higher on thinner plate compared with that of thicker plate. Although the width of fusion zone remained unaffected, the depth of penetration decreased with increase in thickness ratio at same heat input rate. Fusion zone consisted of columnar grains with lamellar widmanstatten features, while HAZ consisted of equiaxed grain with randomly oriented small acicular α-Zr phase in β-Zr phase. A small amount of fine second-phase particles of Zr(Fe,Cr)2 was identified in the fusion zone, which affected the tensile properties marginally. Weld failed in the base metal during tensile test, and YS and UTS are found to be comparable to that of base metal. However, the ductility and notch toughness of the joint was found to be inferior to those of base metal, which deteriorated with increase in thickness ratio. At constant heat input, porosity was found to be higher in dissimilar joint than its similar counterpart, which might be one of the reasons for inferior ductility and notch impact strength in addition to unfavourable microstructural features.

Similar content being viewed by others

References

Tao W, Cai C, Li L, Chen Y, Wang YL (2013) Pulsed laser spot welding of intersection points for Zircaloy-4 spacer grid assembly. Mater Des 52:487–494

Kumar NAPK, Szpunar JA, He Z (2011) Microstructural studies and crystallographic orientation of different zones and δ-hydrides in resistance welded zircaloy-4 sheets. J Nucl Mater 414:341–351

Mastanaiah P, Sharma A, Madhusudhan Reddy G (2018) Process parameters-weld bead geometry interactions and their influence on mechanical properties: a case of dissimilar aluminium alloy electron beam welds. Def Technol 14:137–150

Zhang B, Li X, Wang T, Wang X (2015) Microstructure and corrosion behavior of Zr-702 joined by electron beam welding. Vacuum 121:159–165

Kou S (2003) Welding metallurgy. Wiley, Hoboken

Gao F, Gao Q, Jiang P, Liu Z, Liao Z (2019) Microstructure and properties of titanium alloy electron beam weldments based on the different heat input conditions of the same energy. Vacuum 146:136–141

Zhang Z, Jing H, Xu L, Han Y, Zhao L, Lv X, Zhang J (2018) Influence of heat input in electron beam process on microstructure and properties of duplex stainless steel welded interface. Appl Surf Sci 435:352–366

Xia X, Wu J, Liu Z, Shen X, Ma J, Liu Z (2019) Study of microstructure difference properties of electron beam welds with beam oscillation of 50mm 316L in CFETR. Fusion Eng Des 138:339–346

Schultz DH (1993) Electron beam welding. Abington publishing

Han Q, Kim D, Kim D, Lee H, Kim N (2012) Laser pulsed welding in thin sheets of Zircaloy-4. J Mater Process Technol 212:1116–1122

Hajitabar A, Naffakh-Moosavy H (2018) Effect of electron beam welding current variations on the microstructure and mechanical properties of Nb-1Zr advanced alloy. Vacuum 150:196–202

Hajitabar A, Naffakh-Moosavy H (2017) Electron beam welding of difficult-to-weld austenitic stainless steel/ Nb-based alloy dissimilar joints without interlayer. Vacuum 146:170–178

Hajitabar A, Naffakh-Moosavy H (2018) The effect of Fex Nby (x=2,7 and y=1,6) intermetallics on microstructure and mechanical properties of electron beam welded Nb-1Zr refractory alloy. Int J Refract Met Hard Mater 76:192–203

Silva CM, Leonard KJ, Abel EV, Geringer JW, Bryan CD (2018) Investigation of mechanical and microstructural properties of Zircaloy-4 under different experimental conditions. J Nucl Mater 499:546–557

Hashemzadeh M, Chen BQ, Soares CG (2015) Numerical and experimental study on butt weld with dissimilar thickness of thin stainless steel plate. Int J Adv Manuf Technol 78:319–330

Xia J, Jin H (2017) Numerical study of welding simulation and residual stress on butt welding of dissimilar thickness of austenitic stainless steel. Int J Adv Manuf Technol 91:227–235

Nakhodchi S, Shokuhfar A, Iraj SA, Thomas BG (2015) Evolution of temperature distribution and microstructure in multipass welded AISI 321 stainless steel plates with different thicknesses. J Press Vessel Technol 137:061405

Nayak LJ, Roy GG (2020) Thermocouple temperature measurement during high speed electron beam welding of SS304. Optik 201:163538

Wu CS,Wang HG, ZhangYM(2006) A new heat sourcemodel for keyhole plasma arcwelding in FEManalysis of temperature profile. Weld Res 85:284s–291s

Parga CJ, Rooyen IJV, Coryell BD, Lloyd WR, Valenti LN, Usman H (2017) Room temperature mechanical properties of electron beam welded zircaloy-4 sheet. J Mater Process Technol 241:73–85

Livingstone S, Xiao L, Corcoran EC, Ferrier GA, Potter KN (2015) Development of laser welded appendages to zircaloy-4 fuel tubing (sheath/cladding). Nucl Eng Des 284:97–105

Lathabai S, Jarvis BL, Barton KJ (2008) Keyhole gas tungsten arc welding of commercially pure zirconium. Sci Technol Weld Join 13:573–581

Sande JBV, Bement AL (1974) An investigation of second phase particles in zircaloy-4 alloys. J Nucl Mater 52:115–118

Cao X, Jahazi M (2009) Effect of welding speed on butt joint quality of Ti–6Al–4V alloy welded using a high-power Nd: YAG laser. Opt Lasers Eng 47:1231–1241

Casalino G, Mortello M, Campanelli SL (2015) Ytterbium fiber laser welding of Ti6Al4V alloy. J Manuf Process 20:250–256

Kar J, Roy SK, Roy GG (2017) Effect of beam oscillation on microstructure and mechanical properties of AISI 316L electron beam welds. Metall Mater Trans A 48A:1759–1770

Deng Y, Guan Q, Wu B, Tao J (2015) A comparative study on electron beam welding and rigid restraint thermal self-compressing bonding for Ti6 Al4 V alloy. Vacuum 117:17–22

Kar J, Chakrabarti D, Royand SK, Roy GG (2019) Beam oscillation, porosity formation and fatigue properties of electron beam welded Ti-6Al-4V alloy. J Mater Process Technol 266:165–172

Lee MF, Huang JC, Ho NJ (1996) Microstructural and mechanical characterization of laser-beam welding of a 8090 AI-Li thin sheet. J Mater Sci 35:1455–1468

Yan S, Zhu Z, Ma C, Qin Q, Chen H, Fu YN (2019) Porosity formation and its effect on the properties of hybrid laser welded Al alloy joints. Int J Adv Manuf Technol 104:2645–2656

Bunaziv I, Akselsen OM, Salminen A, Unt A (2016) Fiber laser-MIG hybrid welding of 5 mm 5083 aluminum alloy. J Mater Process Technol 233:107–114

Funding

The authors received financial help from Board of Research for Nuclear Science, Department of Atomic Energy; Government of India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nayak, L.J., Roy, G.G. Joining of zircaloy-4 of dissimilar thickness using electron beam welding. Int J Adv Manuf Technol 110, 2323–2340 (2020). https://doi.org/10.1007/s00170-020-06000-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06000-7