Abstract

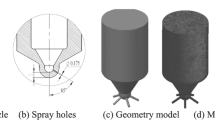

The application of abrasive suspension flow machining (ASFM) to grind a diesel engine injector nozzle is discussed in this paper. The purpose is to remove the sharp corners of the spray holes and improve the fuel flow through the injector nozzle. The proposed method adopts one-way flow to grind the spray holes for high-efficiency production. Compared with traditional reciprocating flow grinding methods using abrasive pastes, the viscosity of slurry and abrasive concentration of ASFM are lower, better for more smooth flow. To achieve a good grinding performance, it is important to determine proper viscosity and concentration. For this purpose, a design of experiments (DoE) method is adopted. In this paper, an orthogonal test method is combined with a non-linear regression method to optimize the process parameters. Through a range analysis on experiment results, the optimal process conditions in terms of the grinding efficiency and the grinding quality are determined. Experiment verifications show that the optimized process parameters can significantly improve the ASFM grinding efficiency and grinding quality.

Similar content being viewed by others

References

Gorana VK, Jain VK, Lal GK (2004) Experimental investigation into cutting forces and active grain density during abrasive flow machining. Int J Mach Tool Manu 44:201–211. https://doi.org/10.1016/j.ijmachtools.2003.10.004

Jung D, Wang WL, Knafl A, Jacobs TJ, Hu SJ, Assanis DN (2008) Experimental investigation of abrasive flow machining effects on injector nozzle geometries, engine performance, and emissions in a DI diesel engine. Int J Automot Technol 9:9–15. https://doi.org/10.1007/s12239-008-0002-0

Jain RK, Jain VK, Dixit PM (1999) Modeling of material removal and surface roughness in abrasive flow machining process. Int J Mach Tool Manu 39:1903–1923. https://doi.org/10.1016/S0890-6955(99)00038-3

Hu GH, Zhu WH, Cai HX (2009) Mathematical model for abrasive suspension jet cutting based on orthogonal test design. J Shanghai Univ (Engl Ed) 13:37–44. https://doi.org/10.1007/s11741-009-0108-2

Jain VK, Adsul SG (2000) Experimental investigations into abrasive flow machining (AFM). Int J Mach Tool Manu 40:1003–1021. https://doi.org/10.1016/S0890-6955(99)00114-5

Tsai FC, Yan BH, Kuan CY, Huang FY (2008) A Taguchi and experimental investigation into the optimal processing conditions for the abrasive jet polishing of SKD61 mold steel. Int J Mach Tool Manu 48:932–945. https://doi.org/10.1016/j.ijmachtools.2007.08.019

Cai HX, Liu W (2017) A prediction method for the precision of extrusion grinding of a needle valve body. Prod Eng 11:295–305. https://doi.org/10.1007/s11740-017-0723-x

Singh S, Shan HS (2002) Development of magneto abrasive flow machining process. Int J Mach Tool Manu 42:953–959. https://doi.org/10.1016/S0890-6955(02)00021-4

Jha S, Jain VK (2004) Design and development of the magnetorheological abrasive flow finishing (MRAFF) process. Int J Mach Tool Manu 44:1019–1029. https://doi.org/10.1016/j.ijmachtools.2004.03.007

Dabrowski L, Marciniak M, Szewczyk T (2006) Analysis of abrasive flow machining with an electrochemical process aid. Proc Inst Mech Eng B J Eng Manuf 220:397–403. https://doi.org/10.1243/095440506X77571

Brar BS, Walia RS, Singh VP (2015) Electrochemical-aided abrasive flow machining (ECA2FM) process: a hybrid machining process. Int J Adv Manuf Technol 79:329–342. https://doi.org/10.1007/s00170-015-6806-y

Yang SC, Mao TF, Tsai FC, Huang HC (2015) Studies of micro-hole burr improvement for aluminum alloy materials using vibrated abrasive grinding machining. Key Eng Mater 642:202–206. https://doi.org/10.4028/www.scientific.net/KEM.642.202

Zhang GZ, Han J (2018) Study on honing mechanism of gear surface using an internal honing wheel based on single-particle abrasive. Key Eng Mater 764:235–244. https://doi.org/10.4028/www.scientific.net/KEM.764.235

Tsegaw AA, Shiou FJ (2015) Development of a small rotary multi-jet abrasive fluid jet polishing tool. Key Eng Mater 625:140–148. https://doi.org/10.4028/www.scientific.net/KEM.625.140

Tzeng HJ, Yan BH, Hsu RT, Lin YC (2007) Self-modulating abrasive medium and its application to abrasive flow machining for finishing micro channel surfaces. Int J Adv Manuf Technol 32:1163–1169. https://doi.org/10.1007/s00170-006-0423-8

Tzeng HJ, Yan BH, Hsu RT, Chow HM (2007) Finishing effect of abrasive flow machining on micro slit fabricated by wire-EDM. Int J Adv Manuf Technol 34:649–656. https://doi.org/10.1007/s00170-006-0632-1

Bai Y, Fan LY, Ma XZ, Peng HL, Song EZ (2016) Effect of injector parameters on the injection quantity of common rail injection system for diesel engines. Int J Automot Technol 17:567–579. https://doi.org/10.1007/s12239-016-0057-2

Kumar SS, Hiremath SS (2016) A review on abrasive flow machining (AFM). Procedia Technol 25:1297–1304. https://doi.org/10.1016/j.protcy.2016.08.224

Kenda J, Duhovnik J, Tavcar J, Kopac J (2014) Abrasive flow machining applied to plastic gear matrix polishing. Int J Adv Manuf Technol 71:141–151. https://doi.org/10.1007/s00170-013-5461-4

Wang AC, Liu CH, Liang KZ, Pai SH (2007) Study of the rheological properties and the finishing behavior of abrasive gels in abrasive flow machining. J Mech Sci Technol 21:1593–1598. https://doi.org/10.1007/BF03177380

Kar KK, Ravikumar NL, Tailor PB, Ramkumar J, Sathiyamoorthy D (2009) Performance evaluation and rheological characterization of newly developed butyl rubber based media for abrasive flow machining process. J Mater Process Technol 209:2212–2221. https://doi.org/10.1016/j.jmatprotec.2008.05.012

Sankar MR, Jain VK, Ramkumar J, Joshi YM (2011) Rheological characterization of styrene-butadiene based medium and its finishing performance using rotational abrasive flow finishing process. Int J Mach Tool Manu 51:947–957. https://doi.org/10.1016/j.ijmachtools.2011.08.012

Guo J, Song CP, Fu YZ, Au KH, Kum CW, Goh MH, Ren TQ, Huang R, Sun CN (2020) Internal surface quality enhancement of selective laser melted Inconel 718 by abrasive flow machining. J Manuf Sci Eng 142:1–42. https://doi.org/10.1115/1.4047141

Singh S, Kumar D, Sankar MR, Jain VK (2019) Viscoelastic medium modeling and surface roughness simulation of microholes finished by abrasive flow finishing process. Int J Adv Manuf Technol 100:1165–1182. https://doi.org/10.1007/s00170-018-1912-2

Pang KL, Nguyen T, Fan JM, Wang J (2012) Modelling of the micro-channelling process on glasses using an abrasive slurry jet. Int J Mach Tool Manu 53:118–126. https://doi.org/10.1016/j.ijmachtools.2011.10.005

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fang, M., Yu, T. & Xi, F.(. An experimental investigation of abrasive suspension flow machining of injector nozzle based on orthogonal test design. Int J Adv Manuf Technol 110, 1071–1082 (2020). https://doi.org/10.1007/s00170-020-05914-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05914-6