Abstract

The influence of hydrostatic pressure on the wetting and corrosion behavior of a commercially available superhydrophobic coating was studied. Electrochemical impedance spectroscopy (EIS) was used to probe the interface between the substrate and coating, the coating and air layer, and the air layer and electrolyte. It was shown that EIS could effectively be used to study how hydrostatic pressure affects the interface between the coating and electrolyte. Hydrostatic pressure was induced in the system using a modified experimental setup and it was shown that EIS could be used to study the wetting state transition. It was observed that the presence of an air layer at the coating and electrolyte interface is what affects the coating performance and the application of hydrostatic pressure deteriorates the protective properties of the coating. Electrical equivalent circuits were applied to determine the contributions of the air layer to the overall corrosion performance of the system. A phenomenological model has also been presented that represents the mechanism that occurs at the coating and electrolyte interface as the wetting state transition occurs.

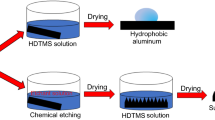

Graphical abstract

Similar content being viewed by others

References

Payer JH (1978) Economic effects of metallic corrosion in the United States--Appendix B.: a report to NBS by Battelle Columbus Laboratories. US Dept. of Commerce, National Bureau of Standards

Sørensen PA, Kiil S, Dam-Johansen K, Weinell CE (2009) Anticorrosive coatings: a review. J Coat Technol Res 6:135–176

Shon M, Kwon H (2009) Comparison of surface modification with amino terminated polydimethylsiloxane and amino branched polydimethylsiloxane on the corrosion protection of epoxy coating. Corros Sci 51:650–657

Zhou Q, Wang Y (2013) Comparisons of clear coating degradation in NaCl solution and pure water. Prog Org Coat 76:1674–1682

Liu B, Fang Z, Wang H, Wang T (2013) Effect of cross linking degree and adhesion force on the anti-corrosion performance of epoxy coatings under simulated deep sea environment. Prog Org Coat 76:1814–1818

Su Y, Kravets VG, Wong SL, Waters J, Geim AK, Nair RR (2014) Impermeable barrier films and protective coatings based on reduced graphene oxide. Nat Commun 5:4843

Ejenstam L, Swerin A, Pan J, Claesson PM (2015) Corrosion protection by hydrophobic silica particle-polydimethylsiloxane composite coatings. Corros Sci 99:89–97

Ishizaki T, Hieda J, Saito N, Saito N, Takai O (2010) Corrosion resistance and chemical stability of super-hydrophobic film deposited on magnesium alloy AZ31 by microwave plasma-enhanced chemical vapor deposition. Electrochim Acta 55:7094–7101

Liu T, Yin Y, Chen S, Chang X, Cheng S (2007) Super-hydrophobic surfaces improve corrosion resistance of copper in seawater. Electrochim Acta 52:3709–3713

Liu K, Jiang L (2011) Metallic surfaces with special wettability. Nanoscale 3:825–838

He T, Wang Y, Zhang Y, lv Q, Xu T, Liu T (2009) Super-hydrophobic surface treatment as corrosion protection for aluminum in seawater. Corros Sci 51:1757–1761

Qiu R, Zhang D, Wang P (2013) Superhydrophobic-carbon fibre growth on a zinc surface for corrosion inhibition. Corros Sci 66:350–359

Wang P, Zhang D, Qiu R (2012) Liquid/solid contact mode of super-hydrophobic film in aqueous solution and its effect on corrosion resistance. Corros Sci 54:77–84

Wang P, Zhang D, Qiu R, Wan Y, Wu J (2014) Green approach to fabrication of a super-hydrophobic film on copper and the consequent corrosion resistance. Corros Sci 80:366–373

Liu Y, Yin X, Zhang J, Yu S, Han Z, Ren L (2014) A electro-deposition process for fabrication of biomimetic super-hydrophobic surface and its corrosion resistance on magnesium alloy. Electrochim Acta 125:395–403

Wang S, Feng L, Jiang L (2006) One-step solution-immersion process for the fabrication of stable bionic superhydrophobic surfaces. Adv Mater 18:767–770

Wang Q, Li J, Zhang C, Qu X, Liu J, Yang Z (2010) Regenerative superhydrophobic coating from microcapsules. J Mater Chem 20:3211–3215

Barthlott W, Neinhuis C (1997) Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 202:1–8

Lai Y, Lin C, Huang J, Zhuang H, Sun L, Nguyen T (2008) Markedly controllable adhesion of superhydrophobic spongelike nanostructure TiO2 films. Langmuir 24:3867–3873

Thieme M, Frenzel R, Schmidt S, Simon F, Hennig A, Worch H, Lunkwitz K, Scharnweber D (2001) Generation of ultrahydrophobic properties of aluminium–a first step to self-cleaning transparently coated metal surfaces. Adv Eng Mater 3:691–695

Badre C, Pauporte T, Turmine M, Lincot D (2007) Tailoring the wetting behavior of zinc oxide films by using alkylsilane self-assembled monolayers. Superlattice Microst 42:99–102

Bok H-M, Kim S, Yoo S-H, Kim SK, Park S (2008) Synthesis of perpendicular nanorod arrays with hierarchical architecture and water slipping superhydrophobic properties. Langmuir 24:4168–4173

Cao L, Price TP, Weiss M, Gao D (2008) Super water-and oil-repellent surfaces on intrinsically hydrophilic and oleophilic porous silicon films. Langmuir 24:1640–1643

Cui Z, Wang Q, Xiao Y, Su C, Chen Q (2008) The stability of superhydrophobic surfaces tested by high speed current scouring. Appl Surf Sci 254:2911–2916

Feng L, Li S, Li Y, Li H, Zhang L, Zhai J, Song Y, Liu B, Jiang L, Zhu D (2002) Super-hydrophobic surfaces: from natural to artificial. Adv Mater 14:1857–1860

Cassie ABD, Baxter S (1944) Wettability of porous surfaces. Trans Faraday Soc 40:546–551

Wenzel RN (1936) Resistance of solid surfaces to wetting by water. Ind Eng Chem 28:988–994

Deng X, Mammen L, Butt H-J, Vollmer D (2012) Candle soot as a template for a transparent robust superamphiphobic coating. Science (80-) 335:67–70

Xiu Y, Liu Y, Balu B, Hess DW, Wong C (2012) Robust superhydrophobic surfaces prepared with epoxy resin and silica nanoparticles. IEEE Trans Compon Packag Manuf Technol 2:395–401

Xu QF, Mondal B, Lyons AM (2011) Fabricating superhydrophobic polymer surfaces with excellent abrasion resistance by a simple lamination templating method. ACS Appl Mater Interfaces 3:3508–3514

Keegan MH, Nash DH, Stack MM (2013) On erosion issues associated with the leading edge of wind turbine blades. J Phys D Appl Phys 46:383001

Bormashenko E (2015) Progress in understanding wetting transitions on rough surfaces. Adv Colloid Interf Sci 222:92–103

Zheng Q-S, Yu Y, Zhao Z-H (2005) Effects of hydraulic pressure on the stability and transition of wetting modes of superhydrophobic surfaces. Langmuir 21:12207–12212

Ou JF, Fang XZ, Zhao WJ, Lei S, Xue MS, Wang FJ, Li CQ, Lu YL, Li W (2018) Influence of hydrostatic pressure on the corrosion behavior of superhydrophobic surfaces on bare and oxidized aluminum substrates. Langmuir 34:5807–5812

Xue Y, Chu S, Lv P, Duan H (2012) Importance of hierarchical structures in wetting stability on submersed superhydrophobic surfaces. Langmuir 28:9440–9450

Fang W, Guo H-Y, Li B, Li Q, Feng XQ (2018) Revisiting the critical condition for the cassie–wenzel transition on micropillar-structured surfaces. Langmuir 34:3838–3844

Lei L, Li H, Shi J, Chen Y (2010) Diffraction patterns of a water-submerged superhydrophobic grating under pressure. Langmuir 26:3666–3669

Søgaard E, Andersen NK, Smistrup K, Larsen ST, Sun L, Taboryski R (2014) Study of transitions between wetting states on microcavity arrays by optical transmission microscopy. Langmuir 30:12960–12968

Poetes R, Holtzmann K, Franze K, Steiner U (2010) Metastable underwater superhydrophobicity. Phys Rev Lett 105:166104

Amirudin A, Thieny D (1995) Application of electrochemical impedance spectroscopy to study the degradation of polymer-coated metals. Prog Org Coat 26:1–28

Ejenstam L, Ovaskainen L, Rodriguez-Meizoso I, Wågberg L, Pan J, Swerin A, Claesson PM (2013) The effect of superhydrophobic wetting state on corrosion protection–The AKD example. J Colloid Interface Sci 412:56–64

Lundgren M, Allan NL, Cosgrove T, George N (2002) Wetting of water and water/ethanol droplets on a non-polar surface: a molecular dynamics study. Langmuir 18:10462–10466

Wang P, Zhang D, Qiu R, Hou B (2011) Super-hydrophobic film prepared on zinc as corrosion barrier. Corros Sci 53:2080–2086

Shin A, Shon M (2010) Effects of coating thickness and surface treatment on the corrosion protection of diglycidyl ether bisphenol-A based epoxy coated carbon steel. J Ind Eng Chem 16:884–890

Feng XJ, Jiang L (2006) Design and creation of superwetting/antiwetting surfaces. Adv Mater 18:3063–3078

Cassie ABD (1948) Contact angles. Discuss Faraday Soc 3:11–16

Huang YS, Zeng XT, Hu XF, Liu FM (2004) Corrosion resistance properties of electroless nickel composite coatings. Electrochim Acta 49:4313–4319

Lu W-K, Elsenbaumer RL, Wessling B (1995) Corrosion protection of mild steel by coatings containing polyaniline. Synth Met 71:2163–2166

Nosonovsky M, Bhushan B (2008) Patterned nonadhesive surfaces: superhydrophobicity and wetting regime transitions. Langmuir 24:1525–1533

Shreepathi S, Naik SM, Vattipalli MR (2012) Water transportation through organic coatings: correlation between electrochemical impedance measurements, gravimetry, and water vapor permeability. J Coat Technol Res 9:411–422

Van Westing EPM, Ferrari GM, De Wit JHW (1994) The determination of coating performance with impedance measurements—II. Water uptake of coatings. Corros Sci 36:957–977

Akbarinezhad E, Bahremandi M, Faridi HR, Rezaei F (2009) Another approach for ranking and evaluating organic paint coatings via electrochemical impedance spectroscopy. Corros Sci 51:356–363

Acknowledgments

The authors appreciate the financial support by the startup funding from the Department of Mechanical Engineering at the University of Nevada, Reno.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Novel setup and procedure were designed to study the effect of hydrostatic pressure on corrosion inhibition of superhydrophobic coating using electrochemical impedance spectroscopy.

• Hydrostatic pressure significantly affects the protective ability of superhydrophobic coating.

• Wetting state transition occurs due to an increase in hydrostatic pressure.

• The contribution of the air layer to the protective ability of the coating has been analyzed.

Rights and permissions

About this article

Cite this article

Manoj, A., Ramachandran, R. & Menezes, P.L. Influence of hydrostatic pressure on wetting state and corrosion of superhydrophobic coatings. Int J Adv Manuf Technol 110, 457–470 (2020). https://doi.org/10.1007/s00170-020-05896-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05896-5