Abstract

The effects of different autogenous laser beam welding process parameters on the fusion zone (FZ) geometry, microstructure, and tensile mechanical properties were investigated for 5-mm-thick AA2198 alloy sheets. Porosity formation and hot cracking are observed for low laser powers and welding velocities, while the porosity level is essentially reduced with increasing laser power. The characteristic cross-sectional geometry of the welded joints changes with increasing laser power, taking shapes from narrow V shape to rectangular I shape, and the results are discussed based on the “closed” and “open” keyhole formation during laser beam welding. A methodology is exploited in terms of quantifying the geometrical dimensions of the cross-section of the FZ in order to promote the welded joints with a narrow width as well as with a rectangular shape. The optimal process parameters, leading to FZ close to the desirable rectangular I shape and with a low number of defects, are identified. Microstructural analyses reveal a pronounced transition zone in between the FZ and the heat-affected zone, which is subdivided into two narrow zones, the partially melted zone (PMZ) and the equiaxed zone. The narrow width of the FZ and PMZ, as well as the rectangular shape of the FZ, enables the autogenous welded joint to reach good tensile deformation properties.

Similar content being viewed by others

References

Dursun T, Soutis C (2014) Recent developments in advanced aircraft aluminum alloys. Mater Des 56:862–871. https://doi.org/10.1016/j.matdes.2013.12.002

Rioja RJ, Liu J (2012) The evolution of Al-Li base products for aerospace and space applications. Metall Mater Trans A 43:3325–3337. https://doi.org/10.1007/s11661-012-1155-z

Pantelakis SG, Alexopoulos ND (2008) Assessment of the ability of conventional and advanced wrought aluminum alloys for mechanical performance in light-weight applications. Mater Des 29:80–91. https://doi.org/10.1016/j.matdes.2006.12.004

Alexopoulos ND, Migklis E, Stylianos A, Myriounis DP (2013) Fatigue behavior of the aeronautical Al–Li (2198) aluminum alloy under constant amplitude loading. Int J Fatigue 56:95–105. https://doi.org/10.1016/j.ijfatigue.2013.07.009

Alexopoulos ND, Proiou A, Dietzel W, Blawert C, Heitmann V, Zheludkevich M, Kourkoulis SK (2016) Mechanical properties degradation of (Al-Cu-Li) 2198 alloy due to corrosion exposure. Procedia Struct Integrity 2:597–603. https://doi.org/10.1016/j.prostr.2016.06.077

Yoshimura R, Konno TJ, Abe E, Hiragaa K (2003) Transmission electron microscopy study of the evolution of precipitates in aged Al–Li–Cu alloys: the θ′ and T1 phases. Acta Mater 51:4251–4266. https://doi.org/10.1016/S1359-6454(03)00253-2

Heinz A, Haszler A, Keidel C, Moldenhauer S, Benedictus R, Miller WS (2000) Recent development in aluminium alloys for aerospace applications. Mater Sci Eng A 280:102–107. https://doi.org/10.1016/S0921-5093(99)00674-7

Lavernia EJ, Grant NJ (1987) Aluminium-lithium alloys. J Mater Sci 122:1521–1529. https://doi.org/10.1007/BF01132370

Starke EA, Staley JT (1996) Application of modern aluminum alloys to aircraft. Prog Aerosp Sci 32:131–172. https://doi.org/10.1016/0376-0421(95)00004-6

Gialos AA, Zeimpekis V, Alexopoulos ND, Kashaev N, Riekehr S, Karanika A (2018) Investigating the impact of sustainability in the production of aeronautical subscale components. J Clean Prod 176:785–799. https://doi.org/10.1016/j.jclepro.2017.12.151

Dittrich D, Standfuss J, Liebscher J, Brenner B, Beyer E (2011) Laser beam welding of hard to weld Al alloys for regional aircraft fuselage design–first results. Phys Procedia 12:113–122. https://doi.org/10.1016/j.phpro.2011.03.015

Chen L, Gong S (2011) The research on YAG laser welding porosity of Al-Li alloy. Adv Mater Res 287-290:2175–2180. https://doi.org/10.4028/www.scientific.net/AMR.287-290.2175

Xiao R, Zhang X (2014) Problems and issues in laser beam welding of aluminum-lithium alloys. J Manuf Process 16:166–175. https://doi.org/10.1016/j.jmapro.2013.10.005

Enz J, Carrarin C, Riekehr S, Ventzke V, Kashaev N (2018) Hot cracking behavior of an autogenously laser welded Al-Cu-Li alloy. Int J Adv Manuf Technol 95:299–310. https://doi.org/10.1007/s00170-017-1197-x

Kostrivas A, Lippold JC (1999) Weldability of Li-bearing Aluminium Alloys. Int Mater Rev 44:217–237. https://doi.org/10.1179/095066099101528289

Kashaev N, Ventzke V, Çam G (2018) Prospects of laser beam welding and friction stir welding processes for aluminum airframe structural applications. J Manuf Process 36:571–600. https://doi.org/10.1016/j.jmapro.2018.10.005

Lu G, Zhang L, Pie Y, Ning J, Zhang J (2018) Study on the size effects of H-Shaped fusion zone of fiber laser welded AZ31 joint. Metals 8:198–212. https://doi.org/10.3390/met8040198

Ahn J, Chen L, He E, Davies CM, Dear JP (2017) Effect of filler feed rate and composition on microstructure and mechanical properties of fibre laser welded AA2024-T3. J Manuf Process 25:26–36. https://doi.org/10.1016/j.jmapro.2016.10.006

Oliveira PI, Costa JM, Loureiro A (2018) Effect of laser beam welding parameters on morphology and strength of dissimilar AA2024/AA7075 T-joints. J Manuf Process 35:149–160. https://doi.org/10.1016/j.jmapro.2018.08.003

Enz J, Riekehr S, Ventzke V, Huber N, Kashaev N (2016) Fiber laser welding of high-alloyed Al-Zn-Mg-Cu alloys. J Mater Process Technol 237:155–162. https://doi.org/10.1016/j.jmatprotec.2016.06.002

Zhang X, Huang T, Yang W, Xiao R, Liu Z, Li L (2016) Microstructure and mechanical properties of laser beam-welded AA2060 Al-Li alloy. J Mater Process Technol 237:301–308. https://doi.org/10.1016/j.jmatprotec.2016.06.021

Liu F, Wang X, Zhou B, Huang C, Lyu F (2018) Corrosion resistance of 2060 aluminum–lithium alloy LBW welds filled with Al-5.6Cu wire. Materials 11:1988. https://doi.org/10.3390/ma11101988

Han B, Tao W, Chen Y, Li H (2017) Double-sided laser beam welded T-joints for aluminum-lithium alloy aircraft fuselage panels: effects of filler elements on microstructure and mechanical properties. Opt Laser Technol 93:99–108. https://doi.org/10.1016/j.optlastec.2017.02.004

Zhang X, Yang W, Xiao R (2015) Microstructure and mechanical properties of laser beam welded Al-Li alloy 2060 with Al-Mg filler wire. Mater Des 88:446–450. https://doi.org/10.1016/j.matdes.2015.08.144

Wang X, Lu F, Wang HP, Qu Z, Xia L (2016) Micro-scale model based study of solidification cracking formation mechanism in Al fiber laser welds. J Mater Process Technol 231:18–26. https://doi.org/10.1016/j.jmatprotec.2015.12.006

Ning J, Zhang L, Bai Q, Yin X, Niu J, Zhang J (2017) Comparison of the microstructure and mechanical performance of 2A97 Al-Li alloy joints between autogenous and non-autogenous laser welding. Mater Des 120:144–156. https://doi.org/10.1016/j.matdes.2017.02.003

Malikov A, Orishich A, Golyshev A, Karpov E (2019) Manufacturing of high-strength laser welded joints of an industrial aluminum alloy of system Al-Cu-Li by means of post heat treatment. J Manuf Process 41:101–110. https://doi.org/10.1016/j.jmapro.2019.03.037

Tian Y, Robson JD, Riekehr S, Kashaev N, Wang L, Lowe T, Karanika A (2016) Process optimization of dual-laser beam welding of advanced Al-Li alloys through hot cracking susceptibility modeling. Metall Mater Trans A 157:3533–3544. https://doi.org/10.1007/s11661-016-3509-4

Krasnoperov MY, Pieters RRGM, Richardson IM (2014) Weld pool geometry during keyhole laser welding of thin steel sheets. Sci Technol Weld Join 9:501–506. https://doi.org/10.1179/136217104225021733

Gao XL, Zhang LJ, Liu J, Zhang JX (2014) Effect of weld cross-section profiles and microstructure on properties of pulsed Nd:YAG laser welding of Ti6Al4V sheet. Int J Adv Manuf Technol 72:895–903. https://doi.org/10.1007/s00170-014-5722-x

Novikov II, Grushko OE (1995) Hot cracking susceptibility of Al–Cu–Li and Al–Cu–Li–Mn alloys. J Mater Sci Technol 11(9):926–932. https://doi.org/10.1179/mst.1995.11.9.926

Han J, Wang J, Zhang M, Niu K (2019) Susceptibility of lithium containing aluminum alloys to cracking during solidification. Materialia 5:100203. https://doi.org/10.1016/j.mtla.2018.100203

Whitaker IR, McCartney DG, Calder N, Steen WM (1993) Microstructural characterization of CO2 laser welds in the Al-Li based alloy 8090. J Mater Sci 28:5469–5478. https://doi.org/10.1007/BF00367817

Ahn J, Chen L, He E, Dear JP, Davies CM (2018) Optimisation of process parameters and weld shape of high power Yb-fibre laser welded 2024-T3 aluminium alloy. J Manuf Process 34:70–85. https://doi.org/10.1016/j.jmapro.2018.05.028

Lin R, Wang HP, Lu F, Solomon J, Carlson BE (2017) Numerical study of keyhole dynamics and keyhole-induced porosity formation in remote laser welding of Al alloys. Int J Heat Mass Transf 108:244–256. https://doi.org/10.1016/j.ijheatmasstransfer.2016.12.019

Ehlen G, Ludwig A, Sahm PR (2003) Simulation of time-dependent pool shape during laser spot welding: transient effects. Metall Mater Trans A 34:2947–2961. https://doi.org/10.1007/s11661-003-0194-x

Zhang M, Chen G, Zhou Y, Liao S (2014) Optimization of deep penetration laser welding of thick stainless steel with a 10 kW fiber laser. Mater Des 53:568–576. https://doi.org/10.1016/j.matdes.2013.06.066

Fu B, Qin G, Meng X, Ji Y, Zou Y, Lei Z (2014) Microstructure and mechanical properties of newly developed aluminum-lithium alloy 2A97 welded by fiber laser. Mater Sci Eng A 617:1–11. https://doi.org/10.1016/j.msea.2014.08.038

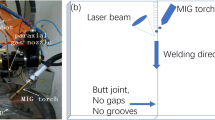

Faraji AH, Moradi M, Goodarzi M, Colucci P, Maletta C (2017) An investigation on capability of hybrid Nd:YAG laser-TIG welding technology for AA2198 Al-Li alloy. Opt Lasers Eng 96:1–6. https://doi.org/10.1016/j.optlaseng.2017.04.004

Wang S, Huang Y, Zhao L (2018) Effects of different aging treatments on the microstructures and mechanical properties of Al-Cu-Li alloy joints welded by electron beam welding. Chin J Aeronaut 31:363–369. https://doi.org/10.1016/j.cja.2017.07.002

Shi Y, Zhong F, Li X, Gong S, Chen L (2007) Effect of laser beam welding on tear toughness of a 1420 aluminum alloy thin sheet. Mater Sci Eng A 465:153–159. https://doi.org/10.1016/j.msea.2007.02.079

Examilioti TN, Klusemann B, Kashaev N, Riekehr S, Enz J, Alexopoulos ND (2017) Anisotropy and size effect in tensile mechanical properties of AL-Cu-Li 2198 alloy. Procedia Struct Integrity 5:13–18. https://doi.org/10.1016/j.prostr.2017.07.052

Dhondt M, Aubert I, Saintier N, Olive JM (2015) Mechanical behavior of periodical microstructure induced by friction stir welding on Al–Cu–Li 2050 alloy. Mater Sci Eng A 644:69–75. https://doi.org/10.1016/j.msea.2015.05.072

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Examilioti, T.N., Kashaev, N., Enz, J. et al. On the influence of laser beam welding parameters for autogenous AA2198 welded joints. Int J Adv Manuf Technol 110, 2079–2092 (2020). https://doi.org/10.1007/s00170-020-05893-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05893-8