Abstract

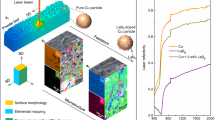

This paper presents a hybrid additive manufacturing (3D Printing) process for fabricating functionally gradient materials. A multi-axis robot was integrated with microextrusion, picojet, and fiber laser systems to deposit conductive traces of different materials. Laser and furnace curing mechanisms were investigated to evaluate their effect on grain morphology and electrical resistivity of the traces. An increase in the number of laser passes resulted in microstructure evolution from a powder-like to densely packed structure for different materials (Ag, Ni, and C). The laser curing mechanism offered lower resistivity and rapid curing times (< 1 min) compared with furnace curing (> 2 h). Optimal sintering parameters were obtained for 4-pass laser at 18 W with comparable resistivity with bulk materials. Localized infiltration (doping) of nanoparticle silver within the micro-extruded carbon trace demonstrated a significant enhancement in electrical properties (two orders of magnitude reduction in resistivity). The energy dispersive x-ray spectroscopy (EDS) mapping of the infiltrated traces displayed uniform dispersion of nano-particulate silver within the carbon matrix. Multilayer-multi-material (MLMM) traces deposited displayed distinctive morphology of each constituent material based on in situ laser curing. Scanning electron microscopy revealed distinctive microstructure and graded elemental composition of different layers (FGM) based on targeted laser sintering of individual materials. The versatile hybrid AM platform provides a basis to fabricate functionally gradient materials (FGMs) for electronic components with several applications.

Similar content being viewed by others

References

Piqué A, Chrisey DB (eds) (2001) Direct-write technologies for rapid prototyping applications: sensors, electronics, and integrated power sources. Elsevier

Hirt L, Reiser A, Spolenak R, Zambelli T (2017) Additive manufacturing of metal structures at the micrometer scale. Adv Mater 29(17):1604211. https://doi.org/10.1002/adma.201604211

Mohammed MG, Kramer R (2017) All-printed flexible and stretchable electronics. Adv Mater 29(19):1604965. https://doi.org/10.1002/adma.201604965

Church KH, Crane NB, Deffenbaugh PI, Ketterl TP, Neff CG, Nesbitt PB, Nussbaum JT et al (2017) Multimaterial and multilayer direct digital manufacturing of 3-D structural microwave electronics. Proc IEEE 105(4):688–701. https://doi.org/10.1109/JPROC.2017.2653178

Yu YZ, Lu JR, Liu J (2017) 3D printing for functional electronics by injection and package of liquid metals into channels of mechanical structures. Mater Des 122:80–89. https://doi.org/10.1016/j.matdes.2017.03.005

Jiang J, Bao B, Li M, Sun J, Zhang C, Yang L, Li F, Yao X, Song Y (2016) Fabrication of transparent multilayer circuits by inkjet printing. Adv Mater 28(7):1420–1426. https://doi.org/10.1002/adma.201503682

Akter T, Desai S (2018) Developing a predictive model for nanoimprint lithography using artificial neural networks. Mater Des. https://doi.org/10.1016/j.matdes.2018.10.005

McKenzie J, Desai S (2018) Investigating sintering mechanisms for additive manufacturing of conductive traces. Amer J Eng App Sci 11(2). https://doi.org/10.3844/ajeassp.2018.652.662

Adarkwa E, Desai S (2016) Scalable droplet based manufacturing using in-flight laser evaporation. J NanoEng NanoManuf 6(2):87–92. https://doi.org/10.1166/jnan.2016.1265

Desai S, Craps M, Esho T (2013) Direct writing of nanomaterials for flexible thin-film transistors (fTFTs). Int J Adv Manuf Technol 64(1-4):537–543. https://doi.org/10.1007/s00170-012-4425-4

Desai S, Yang M, Xu Z, Sankar J (2014) Direct write manufacturing of solid oxide fuel cells for green energy. Journal of Environmental Research and Development 8(3):477

Palmer JA, Summers JL, Davis DW, Gallegos PL, Chavez BD, Yang P, Medina F, Wicker RB (2005) Realizing 3-D interconnected direct write electronics within smart stereolithography structures. In: ASME 2005 International Mechanical Engineering Congress and Exposition. American Society of Mechanical Engineers, pp 287–293. https://doi.org/10.1115/IMECE2005-79360

Määttänen A, Ihalainen P, Pulkkinen P, Wang S, Tenhu H, Peltonen J (2012) Inkjet-printed gold electrodes on paper: characterization and functionalization. ACS Appl Mater Interfaces 4(2):955–964. https://doi.org/10.1021/am201609w

Han Y, Dong J (2017) High-resolution electrohydrodynamic (EHD) direct printing of molten metal. Procedia Manuf 10:845–850. https://doi.org/10.1016/j.promfg.2017.07.070

Jeong S, Song HC, Lee WW, Lee SS, Choi Y, Son W, Kim ED, Paik CH, Oh SH, Ryu B-H (2011) Stable aqueous based Cu nanoparticle ink for printing well-defined highly conductive features on a plastic substrate. Langmuir 27(6):3144–3149. https://doi.org/10.1021/la104136w

Boley JW, White EL, Chiu GTC, Kramer RK (2014) Direct writing of gallium-indium alloy for stretchable electronics. Adv Funct Mater 24(23):3501–3507. https://doi.org/10.1002/adfm.201303220

Wang Y, Chen C, Xie H, Gao T, Yao Y, Pastel G, Han X et al (2017) 3D-printed all-fiber li-ion battery toward wearable energy storage. Adv Funct Mater 27(43):1703140. https://doi.org/10.1002/adfm.201703140

Dickey MD (2017) Stretchable and soft electronics using liquid metals. Adv Mater 29(27):1606425. https://doi.org/10.1002/adma.201606425

Ahn BY, Walker SB, Slimmer SC, Russo A, Gupta A, Kranz S, Duoss EB, Malkowski TF, Lewis JA (2011) Planar and three-dimensional printing of conductive inks. J Vis Exp 58. https://doi.org/10.3791/3189

Shen A, Caldwell D, Ma AWK, Dardona S (2018) Direct write fabrication of high-density parallel silver interconnects. Addit Manuf 22:343–350. https://doi.org/10.1016/j.addma.2018.05.010

Roshanghias A, Krivec M, Baumgart M (2017) Sintering strategies for inkjet printed metallic traces in 3D printed electronics. Flex Print 2(4):045002. https://doi.org/10.1088/2058-8585/aa8ed8

Allen ML, Aronniemi M, Mattila T, Alastalo A, Ojanperä K, Suhonen M, Seppä H (2008) Electrical sintering of nanoparticle structures. Nanotechnology 19(17):175201. https://doi.org/10.1088/0957-4484/19/17/175201

Fujii S, Kawamura S, Mochizuki D, Maitani MM, Suzuki E, Wada Y (2015) Microwave sintering of Ag-nanoparticle thin films on a polyimide substrate. AIP Adv 5(12):127226. https://doi.org/10.1063/1.4939095

Perelaer J, De Gans BJ, Schubert US (2006) Ink-jet printing and microwave sintering of conductive silver tracks. Adv Mater 18(16):2101–2104. https://doi.org/10.1002/adma.200502422

Roberson DA, Wicker RB, Murr LE, Church K, MacDonald E (2011) Microstructural and process characterization of conductive traces printed from Ag particulate inks. Materials 4(6):963–979. https://doi.org/10.3390/ma4060963

Dermanaki-Farahani R, Lebel LL, Therriault D (2014) Manufacturing of three-dimensionally microstructured nanocomposites through microfluidic infiltration. J Vis Exp 85. https://doi.org/10.3791/51512

Wang C, Tomov RI, Mitchell-Williams TB, Kumar RV, Glowacki BA (2017) Inkjet printing infiltration of Ni-Gd: CeO2 anodes for low temperature solid oxide fuel cells. J Appl Electrochem 47(11):1227–1238. https://doi.org/10.1007/s10800-017-1114-x

Aboushelib MN, Kleverlaan CJ, Feilzer AJ (2007) Selective infiltration-etching technique for a strong and durable bond of resin cements to zirconia-based materials. J Prosthet Dent 98(5):379–388. https://doi.org/10.1016/S0022-3913(07)60123-1

Shin UH, Jeong DW, Kim SH, Lee HW, Kim JM (2014) Elastomer-infiltrated vertically aligned carbon nanotube film-based wavy-configured stretchable conductors. ACS Appl Mater Interfaces 6(15):12909–12914. https://doi.org/10.1021/am502851e

Miyamoto Y, Kaysser WA, Rabin BH, Kawasaki A, Ford RG (eds) (2013) Functionally graded materials: design, processing and applications, vol 5. Springer Science & Business Media. https://doi.org/10.1007/978-1-4615-5301-4

Udupa G, Rao SS, Gangadharan KV (2014) Functionally graded composite materials: an overview. Procedia Mater Sci 5:1291–1299. https://doi.org/10.1016/j.mspro.2014.07.442

Wohlers T, Gornet T History of additive manufacturing, Wohlers report 2016, accessed: 10, 2017.

Elhoone H, Zhang T, Anwar M, Desai S (2020) Cyber-based design for additive manufacturing using artificial neural networks for Industry 4.0. Int J Prod Res 58(9):2841–2861. https://doi.org/10.1080/00207543.2019.1671627

Altubaishe B, Clarke J, Mc Williams C, Desai S (2019) Comparative analysis of risk management strategies for additive manufacturing supply chains. Amer J Eng App Sci 16:273–282. https://doi.org/10.3844/ajassp.2019.273.282

Haeberle G, Desai S (2019) Investigating rapid thermoform tooling via additive manufacturing (3d printing). Amer J Eng App Sci 16:238–243. https://doi.org/10.3844/ajassp.2019.238.243

Parupelli SK, Desai S (2019) A comprehensive review of additive manufacturing (3d printing): processes, applications and future potential. Amer J Eng App Sci 16:244–272. https://doi.org/10.3844/ajassp.2019.244.272

Desai S, Dean C, Desai Y (2018) Cyber-enabled concurrent material and process selection in a flexible design for manufacture paradigm. Int J Adv Manuf Technol 97(5-8):1719–1731. https://doi.org/10.1007/s00170-018-2034-6

Lopes AJ, Lee IH, MacDonald E, Quintana R, Wicker R (2014) Laser curing of silver-based conductive inks for in situ 3D structural electronics fabrication in stereolithography. J Mater Process Technol 214(9):1935–1945. https://doi.org/10.1016/j.jmatprotec.2014.04.009

Parupelli S, Desai S (2017) Amer J Eng App Sci 10(1):264–271. https://doi.org/10.3844/ajeassp.2017.264.271

McKenzie J, Parupelli S, Martin D, Desai S (2017) Presented at IIE Annual Conference. Proceedings. Institute of Industrial and Systems Engineers (IISE), 05.

Skylar-Scott MA, Gunasekaran S, Lewis JA (2016) Laser-assisted direct ink writing of planar and 3D metal architectures. Proc Natl Acad Sci 113(22):6137–6142. https://doi.org/10.1073/pnas.1525131113

Ted Pella, Technical Notes. PELCO® High performance carbon paste, 50 g PNo. 16057.

Ted Pella, Technical Notes. PELCO® High performance nickel paste, 50 g PNo. 16059.

Ted Pella, Technical Notes.PELCO® High performance silver paste, 50 g PNo. 16047.

Ted Pella, Technical Notes. PELCO® NanoXact™ silver colloids/nanoparticles (50 nm).

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH image to ImageJ: 25 years of image analysis. Nat Methods 9(7):671

Huang C, Becker MF, Keto JW, Kovar D (2007) Annealing of nanostructured silver films produced by supersonic deposition of nanoparticles. J Appl Phys 102(5):054308. https://doi.org/10.1038/nmeth.2089

Haque RI (2015) Design and development of printed acoustic sensor (Doctoral dissertation, Ecole Nationale Supérieure des Mines de Saint-Etienne).

Wasley TJ (2016) Digitally driven microfabrication of 3D multilayer embedded electronic systems (Doctoral dissertation, © Thomas James Wasley). https://hdl.handle.net/2134/23237.

Greer JR, Street RA (2007) Thermal cure effects on electrical performance of nanoparticle silver inks. Acta Mater 55(18):6345–6349. https://doi.org/10.1016/j.actamat.2007.07.040

Mei J, Lovell MR, Mickle MH (2005) Formulation and processing of novel conductive solution inks in continuous inkjet printing of 3-D electric circuits. IEEE Trans Electron Packag Manuf 28(3):265–273. https://doi.org/10.1109/TEPM.2005.852542

Soltani A, Vahed BK, Mardoukhi A, Mäntysalo M (2015) Laser sintering of copper nanoparticles on top of silicon substrates. Nanotechnology 27(3):035203. https://doi.org/10.1088/0957-4484/27/3/035203

Thongchai T, Larpkiattaworn S, Atong D, Kitiwan M (2004) Comparison of microwave and conventional sintering of AL2O3-ZrO2 composites. In 18th International Conference on Composite Materials. Pathumthani, Thailand.

Maekawa K, Yamasaki K, Niizeki T, Mita M, Matsuba Y, Terada N, Saito H (2010) Laser sintering of silver nanoparticles for electronic use. In: Materials Science Forum, vol 638. Trans Tech Publications, pp 2085–2090. https://doi.org/10.4028/www.scientific.net/MSF.638-642.2085

Tomov RI, Mitchell-Williams T, Gao C, Kumar RV, Glowacki BA (2017) Performance optimization of LSCF/Gd: CeO 2 composite cathodes via single-step inkjet printing infiltration. J Appl Electrochem 47(5):641–651. https://doi.org/10.1007/s10800-017-1066-1

Bolduc M, Trudeau C, Beaupré P, Cloutier SG, Galarneau P (2018) Thermal dynamics effects using pulse-shaping laser sintering of printed silver inks. Sci Rep 8(1):1418. https://doi.org/10.1038/s41598-018-19801-4

Ho CC, Evans JW, Wright PK (2010) Direct write dispenser printing of a zinc microbattery with an ionic liquid gel electrolyte. J Micromech Microeng 20(10):104009. https://doi.org/10.1088/0960-1317/20/10/104009

Acknowledgments

We would like to thank the Center of Excellence in Product Design and Advanced Manufacturing at North Carolina A&T State University.

Funding

This work was supported by NSF CMMI: award grant # 1435649 and # 1663128. This work was performed in part at the Joint School of Nanoscience and Nanoengineering, a member of the Southeastern Nanotechnology Infrastructure Corridor (SENIC) and National Nanotechnology Coordinated Infrastructure (NNCI), which is supported by the National Science Foundation (grant ECCS-1542174).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Parupelli, S.K., Desai, S. Hybrid additive manufacturing (3D printing) and characterization of functionally gradient materials via in situ laser curing. Int J Adv Manuf Technol 110, 543–556 (2020). https://doi.org/10.1007/s00170-020-05884-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05884-9