Abstract

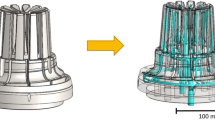

Two-stage punching has been recently developed to reduce the sheared edge sensitivity of advanced high-strength steels by dramatically improving the hole expansion ratio via reduction of internal confinement. However, there is still no way to effectively apply this concept for the large-scale press blanking process. In this paper, a novel two-stage press blanking process is proposed to selectively improve the edge stretchability of third-generation advanced high-strength steels for regions with concentrated edge tensioning. Pre-hole design concepts were newly adopted for selective improvement. In the two-stage blanking with pre-holes, inducing the uniform shearing angle is critical for reducing work hardening and ensuring high sheared edge quality. The process is governed by the design and composition of the pre-hole for the first blanking and specifying the lengths of the blanking gap for the second blanking. The proposed two-stage blanking has been experimentally validated by sheared edge tensioning, sheared edge quality, and microhardness tests. A comparison with waterjet cutting showed that it was possible to achieve remarkable edge stretchability that was similar to that obtained for waterjet cutting.

Similar content being viewed by others

Abbreviations

- AHSS:

-

Advanced high-strength steels

- BIW:

-

Body-in-white

- 3G AHSS:

-

Third-generation AHSS

- HER:

-

Hole expansion ratio

- SET:

-

Sheared edge tensioning

- SAZ:

-

Sheared affected zone

- SEM:

-

Scanning electron microscopy

- DIC:

-

Digital image correlation

- 2D spherocylinders:

-

Two-dimensional spherocylinders

References

Won C, Lee W, Lee HY, Kang YS, Yoon J (2020) Evaluation of in-plane edge stretchability under severe contact condition for third generation advanced high strength steel. Int J Adv Manuf Technol 108:1945–1958

Won C, Kim D, Yoon J (2019) Minimizing wrinkling formation of GPa-grade steels in multi-stage crash forming process. Int J Adv Manuf Technol 105:3325–3335

Wang H, Yan Y, Jia F, Han F (2016) Investigations of fracture on DP980 steel sheet in roll forming process. J Manuf Process 22:177–184

Won C, Lee S, Seo J, Park SH, Yoon J (2018) Stripping failure of punching pin in GPa-grade steels. Int J Adv Manuf Technol 94:73–83

Wang K, Greve L, Wierzbicki T (2015) FE simulation of edge fracture considering pre-damage from blanking process. Int J Solids Struct 71:206–218

Kwon O, Lee K, Kim G, Chin K-G (2010) New trends in advanced high strength steel developments for automotive application. Mater Sci Forum 638-642:136–141

Krizan D, Steineder K, Kaar S, Hebesberger T (2018) Development of third generation advanced high strength steels for automotive applications. Int Conf Transfer 2018, at Trencianske Teplice, Slovakia

Zhou M, Li Y, Hu Q, Li X, Chen J (2019) Investigations on edge quality and its effect on tensile property and fracture patterns of QP980. J Manuf Process 37:509–518

Chan Y, Han S, Li X, Wang C, Zhen G, Dong H (2018) Effect of shearing clearance on formability of sheared edge of the third generation automotive medium-Mn steel with metastable austenite. J Mater Process Technol 259:216–227

Hubert C, Dubar L, Dubar M, Dubois A (2010) Experimental simulation of strip edge cracking in steel rolling sequences. J Mater Process Technol 210:1587–1597

Mori K-I, Abe Y, Suzui Y (2010) Improvement of stretch flangeability of ultra high strength steel sheet by smoothing of sheared edge. J Mater Process Technol 210:653–659

Shih H-C, Shi MF (2011) An innovative shearing process for AHSS edge stretchability improvement. J Manuf Sci Eng 133:2014-01-0994. 061018

Shih H-C, Hsiung C-K, Wendt B (2014) Optimal production trimming process for AHSS edge stretchability improvement. SAE Int 2014-01-0994

Matsuno T, Sato K, Okamoto R, Mizumura M, Suehiro M (2016) Synergy effect of shear angle and anisotropic material ductility on hole-expansion ratio of high-strength steels. J Mater Process Technol 230:167–176

Takahashi Y, Kawano O, Horioka S, Ushioda K (2013) Improvement of stretch flangeability of high-tensile-strength steel sheets by piercing under tension using humped bottom punch. SAE Int 2013-01-0609

Abe Y, Yonekawa R, Sedoguchi K, Mori K-I (2018) Shearing of ultra-high strength steel sheets with step punch. Proc Manuf 15:597–604

Gläsner T, Sunderkötter C, Plath A, Volk W, Hoffmann H, Golle R (2014) Methods to decrease cut edge sensitivity of high strength steels. Key Eng Mater 611:1294–1307 \Trans Tech Publications

Feistle M, Pätzold I, Golle R, Volk W, Frehn A, Ilskens R (2018) Maximizing the expansion ratio through multi-stage shear-cutting process during collar forming. IOP Conf Ser: Mater Sci Eng 418:012071

Li G, Zhou M, Wang W, Xiong H, Chen Z (2018) Accurate trimming line optimization of multi-station progressive die for complex automotive structural parts. Int J Adv Manuf Technol 95:1185–1203

ISO 16630 (2009) Metallic materials-sheet and strip-hole expanding test. ISO- International Organization for Standardization, Geneva

Huang M (2014) A/SP standardization of hole expansion test. In Great designs in STEEL Seminar, AISI, Livonia, USA. Anais

Choi S, Kim K, Lee J, Park SH, Lee HJ, Yoon J (2019) Image processing algorithm for real-time crack inspection in hole expansion test. Int J Precis Eng Manuf 20:1139–1148

Marschall T, Keta YE, Olsson P, Teitel S (2019) Orientational ordering in athermally sheared, aspherical, frictionless particles. Phys Rev Lett 122(18):188002

Subramonian S, Altan T, Ciocirlan B, Campbell C (2013) Optimum selection of variable punch-die clearance to improve tool life in blanking non-symmetric shapes. Int J Mach Tools Manuf 75:63–71

Fleck NA, Olurin OB, Chen C, Ashby MF (2001) The effect of hole size upon the strength of metallic and polymeric foams. J Mech Phys Solids 49:2015–2030

Funding

The author Prof. Jonghun Yoon received research funding from the National Research Foundation of Korea (NRF), grant funded by the Korea Government (MSIT) (No. 2019R1A2C4070160), and “Human Resources Program in Energy Technology” of the Korean Institute of Energy Technology Evaluation and Planning (KETEP), granted by the Ministry of Trade, Industry, and Energy, Republic of Korea (no. 20174010201310).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Won, C., Lee, W., Lee, Hy. et al. Effect of two-stage press blanking on edge stretchability with third-generation advanced high-strength steels. Int J Adv Manuf Technol 110, 13–27 (2020). https://doi.org/10.1007/s00170-020-05854-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05854-1