Abstract

Vehicle weight reduction has been discussed by automotive industry for decades. The current solution for weight reduction purpose is the use of aluminum stamping and casting parts to replace the steel parts. However, joining aluminum with aluminum or aluminum with steel parts would be difficult to select a proper joining technology to ensure a qualified joint. Self-pierce riveting (SPR) as a mechanical joining technique has been used by automotive industry owing to its simplicity, versatility, and environment friendly nature. Although SPR can avoid the joining quality problems caused by welding to join aluminum with steel parts, the other joining problems from SPR still hinder the industry to widely use this joining technology. This article analyzed the cause of cracks on joint button from the understanding of joined material. The modified heat treatments were used to investigate the relationship between eutectic silicon morphology and cracking condition on joint button. In addition, the lap-shear strength according to the samples with various heat treatments was also tested and analyzed. Eventually, the results indicated that silicon content and its morphology take main responsibility on crack initiation and propagation on SPR joint button. But the influence of cracks on joining strength still needs to be investigated and studied in the future work.

Similar content being viewed by others

References

Cheah LW (2010) Cars on a diet: the material and energy impacts of passenger vehicle weight reduction in the US, Massachusetts Institute of Technology

Bandivadekar A et al (2008) On the road in 2035: reducing transportations petroleum consumption and GHG emissions, laboratory for energy and the environment, Massachusetts Institute of Technology

Sakiyama T, Murayama G, Naito Y, Saita K, Miyazaki Y, Oikawa H, Nose T (2013) Dissimilar metal joining technologies for steel sheet and aluminum alloy sheet in auto body. Nippon Steel Tech Rep 103:91–98

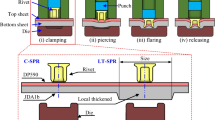

Li D, Chrysanthou A, Patel I, Williams G (2017) Self-piercing riveting-a review. Int J Adv Manuf Technol 92(5–8):1777–1824

Zhao X, Zhang J, Chu YL, Cheng P, Meng D (2020) Research on joining high pressure die casting parts by self-pierce riveting (SPR) ssing ring-groove die comparing to heat treatment method, SAE Technical Paper

Miller WS, Zhuang L, Bottema J, Wittebrood A, De Smet P, Haszler A, Vieregge A (2000) Recent development in aluminium alloys for the automotive industry. Mater Sci Eng: A 280(1):37–49

Porcaro R, Hanssen AG, Langseth M, Aalberg A (2006) The behaviour of a self-piercing riveted connection under quasi-static loading conditions. Int J Solids Struct 43(17):5110–5131

Li B, Fatemi A (2006) An experimental investigation of deformation and fatigue behavior of coach peel riveted joints. Int J Fatigue 28(1):9–18

Khanna SK, Long X, Krishnamoorthy S, Agrawal HN (2006) Fatigue properties and failure characterisation of self-piercing riveted 6111 aluminium sheet joints. Sci Technol Weld Join 11(5):544–549

Li D, Han L, Thornton M, Shergold M (2010) An evaluation of quality and performance of self-piercing riveted high strength aluminium alloy AA6008 for automotive applications. SAE technical paper (no. 2010-01-0223)

Han L, Chrysanthou A (2008) Evaluation of quality and behaviour of self-piercing riveted aluminium to high strength low alloy sheets with different surface coatings. Mater Des 29(2):458–468

Han L, Young KW, Hewitt R, Alkahari MR, Chrysanthou A (2006) Effect of sheet material coatings on quality and strength of self-piercing riveted joints. SAE Technical Paper (No. 2006-01-0775)

Li D, Han L, Thornton M, Shergold M (2012) Influence of edge distance on quality and static behaviour of self-piercing riveted aluminium joints. Mater Des 34:22–31

Li D, Han L, Thornton M, Shergold M, Williams G (2014) The influence of fatigue on the stiffness and remaining static strength of self-piercing riveted aluminium joints. Mater Des 54:301–314

Abe Y, Kato T, Mori K (2006) Joinability of aluminium alloy and mild steel sheets by self piercing rivet. J Mater Process Technol 177(1–3):417–421

Mori K, Kato T, Abe Y, Ravshanbek Y (2006) Plastic joining of ultra high strength steel and aluminium alloy sheets by self piercing rivet. CIRP Ann 55(1):283–286

Li DZ, Han L, Lu ZJ, Thornton M, Shergold M (2012) Influence of die profiles and cracks on joint buttons on the joint quality and mechanical strengths of high strength aluminium alloy joint. Int Adv Mater Res 548:398–405

Chung CS, Kim HK (2016) Fatigue strength of self-piercing riveted joints in lap-shear specimens of aluminium and steel sheets. Fatigue Fract Eng Mater Struct 39(9):1105–1114

Calabrese L, Proverbio E, Di Bella G, Galtieri G, Borsellino C (2015) Failure behaviour of SPR joints after salt spray test. Eng Struct 82:33–43

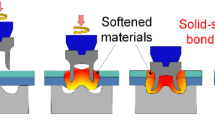

Hahn O, Horstmann M (2007) Mechanical joining of magnesium components by means of inductive heating-realization and capability. Mater Sci Forum 539:1638–1643

Durandet Y, Deam R, Beer A, Song W, Blacket S (2010) Laser assisted self-pierce riveting of AZ31 magnesium alloy strips. Mater Des 31:S13–S16

Tang D, Evans M, Briskham P, Susmel L, Sims N (2018) Modelling and characterisation of a servo self-piercing riveting (SPR) system. J Phys. https://doi.org/10.1088/1742-6596/1106/1/012021

Hartlieb M (2013) Aluminum alloys for structural die casting. Die Cast Eng 57(3):40–43

Jian X, Meek TT, Han Q (2006) Refinement of eutectic silicon phase of aluminum A356 alloy using high-intensity ultrasonic vibration. Scr Mater 54(5):893–896

Derin S, Aybarç U, Birol Y (2017) Effect of strontium addition on microstructure and mechanical properties of AlSi7Mg0. 3 alloy. Int J Met 11(4):688–695

Wang L, Shivkumar S (1995) Strontium modification of aluminium alloy castings in the expendable pattern casting process. J Mater Sci 30(6):1584–1594

Zhao X (2019) Research on applying the self-pierce riveting (SPR) for die casting aluminum alloys. Dissertation, Purdue University

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, X., Meng, D., Zhang, J. et al. The effect of heat treatment on die casting aluminum to apply self-pierce riveting. Int J Adv Manuf Technol 109, 2409–2419 (2020). https://doi.org/10.1007/s00170-020-05833-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05833-6