Abstract

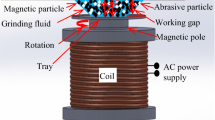

Magnetic abrasive finishing (MAF) is an effective surface finishing method. At present, most of the research on plane MAF focuses on finishing characteristics. However, due to the “edge effect” of the magnetic field and the rotational movement of the magnetic brush, the uniformity and flatness of the finished surface are poor. In order to further improve the accuracy of the finished surface, the surface uniformity and flatness are improved by changing the shape of the magnetic pole and the trajectory of the magnetic brush. At the same time, the surface flatness is evaluated not only by the maximum height difference of the cross section but also by the standard deviation to evaluate the surface uniformity and flatness. Through magnetic field simulation and experiments, it is proved that the bottom groove of the magnetic pole helps to make the magnetic particle distribution more uniform in the processing area, which can effectively improve the surface quality. In addition, through experiments, changing the trajectory of the magnetic brush can also effectively improve the surface flatness of the finished surface.

Similar content being viewed by others

References

Wang Y, Hu DJ (2005) Study on the inner surface finishing of tubing by magnetic abrasive finishing. Int J Mach Tools Manuf 45(1):43–49

Jain NK, Jain VK, Jha S (2007) Parametric optimization of advanced fine-finishing processes. Int J Adv Manuf Technol 34:1191–1213

Misra A, Pandey PM, Dixit US, Roy A, Silberschmidt VV (2019) Multi-objective optimization of ultrasonic-assisted magnetic abrasive finishing process. Int J Adv Manuf Technol 101:1661–1670

Shinmura T, Takazawa K, Hatano E, Matsunaga M, Matsuo T (1990) Study on magnetic abrasive finishing. CIRP Ann 39(1):325–328

Sun X, Zou YH (2017) Development of magnetic abrasive finishing combined with electrolytic process for finishing SUS304 stainless steel plane. Int J Adv Manuf Technol 92(9–12):3373–3384

Shinmura T, Aizawa T (1989) Study on magnetic abrasive finishing process-development of plane finishing apparatus using a stationary type electromagnet. Bull Jpn Soc Precis Eng 23(3):236–239

Shinmura T, Aizawa T (1988) Development of plane magnetic abrasive finishing apparatus and its finishing performance (2nd report) finishing apparatus using a stationary type electromagnet. J Jpn Soc Precis Eng 54(5):928–933 (in Japanese)

Shinmura T, Takazawa K, Hatano E, Aizawa T (1986) Study on magnetic-abrasive finishing (2nd report) finishing characteristics. J Jpn Soc Precis Eng 52(10):1761–1767 (in Japanese)

Yamaguchi H, Shinmura T (2000) Study of an internal magnetic abrasive finishing using a pole rotation system: discussion of the characteristic abrasive behavior. Precis Eng 24:237–244

Jain VK, Kumar P, Behera PK, Jayaswal SC (2001) Effect of working gap and circumferential speed on the performance of magnetic abrasive finishing process. Wear 250(1–12):384–390

Jain VK, Saren KK, Raghuram V, Ravi Sankar M (2019) Force analysis of magnetic abrasive nano-finishing of magnetic and non-magnetic materials. Int J Adv Manuf Technol 100(5–8):1137–1147

Yin SH, Shinmura T (2004) Vertical vibration-assisted magnetic abrasive finishing and deburring for magnesium alloy. Int J Mach Tools Manuf 44:1297–1303

Yin SH, Shinmura T (2004) A comparative study: polishing characteristics and its mechanisms of three vibration modes in vibration-assisted magnetic abrasive polishing. Int J Mach Tools Manuf 44:383–390

Wu JZ, Zou YH, Sugiyama H (2015) Study on ultra-precision magnetic abrasive finishing process using low frequency alternating magnetic field. J Magn Magn Mater 386:50–59

Zou YH, Xie HJ, Dong CW, Wu JZ (2018) Study on complex micro surface finishing of alumina ceramic by the magnetic abrasive finishing process using alternating magnetic field. Int J Adv Manuf Technol 97(5–8):2193–2202

Xie HJ, Zou YH, Dong CW, Wu JZ (2019) Study on the magnetic abrasive finishing process using alternating magnetic field: investigation of mechanism and applied to aluminum alloy plate. Int J Adv Manuf Technol 102(5–8):1509–1520

Misra A, Pandey PM, Dixit US (2017) Modeling and simulation of surface roughness in ultrasonic assisted magnetic abrasive finishing process. Int J Mech Sci 133:344–356

Feng M, Wu YB, Wang YL, Zeng J, Bitoh T, Nomura M, Fujii T (2020) Investigation on the polishing of aspheric surfaces with a doughnut-shaped magnetic compound fluid (MCF) tool using an industrial robot. Precis Eng 61:182–193

Feng M, Wu YB (2018) Fundamental investigation on the polishing aspheric elements with doughnut-shaped MCF slurry. Key Eng Mater 792:179–184

Zou YH, Jiao AY, Aizawa T (2010) Study on plane magnetic abrasive finishing process - experimental and theoretical analysis on polishing trajectory. Adv Mater Res 126:1023–1028

Jiao AY, Quan HJ, Li ZZ, Zou YH (2015) Study on improving the trajectory to elevate the surface quality of plane magnetic abrasive finishing. Int J Adv Manuf Technol 80(9–12):1613–1162

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zou, Y., Xie, H. & Zhang, Y. Study on surface quality improvement of the plane magnetic abrasive finishing process. Int J Adv Manuf Technol 109, 1825–1839 (2020). https://doi.org/10.1007/s00170-020-05759-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05759-z