Abstract

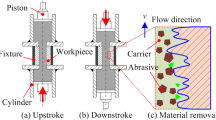

Abrasive flow machining (AFM) is a key internal polishing technology applied to workpieces with difficult-to-reach areas. With the complex viscoelastic responses of abrasive media, the media flow is difficult to predict when the channel geometry is complex. It follows that the process outcome is also difficult to predict. In the present works, we proposed to use both experimental observations and computational fluid dynamics (CFD) simulations to investigate the responses of abrasive media in different branching channels during AFM process. We conducted measurement of media pressure and velocity during AFM for branching channels of different shapes and diameters. These data were used to develop and validate the present numerical model. The CFD simulations were conducted using the viscoelastic solver in OpenFOAM extension version, and we implemented log-conformation tensor representation (LCR) to stabilize the solver for high Weissenberg number problem (HWNP). The benchmark of the present simulations with experiments shows good agreement indicating that the present model is validated. The free-slip phenomenon of the abrasive media on the workpiece was uncovered from experimental observation of media flow in transparent channels and a sudden pressure drop (instead of a linear pressure drop) occurring across the connection between the workpiece and the fixture. Analysis of the numerical data indicates that the first normal stress difference (N1) plays an important role in the mass flow rate distributions of abrasive viscoelastic media in branching channels. Degradation of media properties was also studied and analyzed, suggesting that the flow pattern distribution in the workpieces could be influenced by media property degradation.

Similar content being viewed by others

References

Rhoades L (1991) Abrasive flow machining:a case study. J Mater Process Technol 28:107–116. https://doi.org/10.1016/0924-0136(91)90210-6

Petare AC, Jain NK (2018) A critical review of past research and advances in abrasive flow finishing precess. Int J Adv Manuf Technol V97:741–782

Williams RE, Rajurkar KP (1992) Stochastic modeling and analysis of abrasive flow machining. J Eng Ind 114(1):74–81

Sankar MR, Jain VK, Ramkumar J (2009) Experimental investigations into rotating workpiece abrasive flow finishing. Wear 267(1):43–51

Kohut T (1988) Surface finishing with abrasive flow machining. SME Technical Paper, Proc. 4th International Aluminium Extraction Technology Seminar Washington DC, New York, USA. pp 35–42.

Jain RK, Jain VK, Kalra PK (1999) Modelling of abrasive flow machining process: a neural network approach. Wear 231(2):242–248

Kumar SS, Somashekhar SH (2016) A review on abrasive flow machining (AFM). Procedia Technol 25:1297–1304

Sambharia J,Mali HS (2017) Recent developments in abrasive flow finishing process: a review of current research and future prospects. Proc Inst Mech Eng B J Eng Manuf.

William RE, Rajurkar KP, Rhoades LJ (1989) Performance characteristics of abrasive flow machining. SME Technical paper, FC 89–806 Dearborn, MI, USA, pp 898–906.

Jain NK, Jain VK, Jha S (2007) Parametric optimization of advanced fine-finishing processes. Int J Adv Manuf Technol 34(11):1191–1213

Mali HS, Manna A (2009) Current status and application of abrasive flow finishing processes: a review. Proc Inst Mech Eng B J Eng Manuf 223(7):809–820

Rajeshwar G, Kozak J, Rajurkar KP (1994) Modeling and computer simulation of media flow in abrasive flow machining process. Proceedings of the International Mechanical Engineering Congress and Exposition, ASME, PED 68-2, Chicago, IL, pp 965–971.

Bremerstein T, Potthoff A, Michaelis A, Schmiedel C, Uhlmann E, Blug B, Amann T (2015) Wear of abrasive media and its effect on abrasive flow machining results. Wear 342:44–51

Sankar MR, Jain VK, Ramkumar J (2008) Abrasive flow machining (AFM): an overview, INDO-US Workshop on Smart Machine Tools, Intelligent Machining Systems and Multi-scale Manufacturing, PSG college, Coimbatore, India, pp 1–9.

Loveless TR, Williams RE, Rajurkar KP (1994) A study of the effects of abrasive-flow finishing on various machined surfaces. J Mater Process Technol 47(1):133–151

Petri KL, Billo RE, Bidanda B (1998) A neural network process model for abrasive flow machining operations. JManuf Syst 17(1):52–64

Jain RK, Jain VK, Dixit PM (1999) Modeling of material removal and surface roughness in abrasive flow machining process. Int J Mach Tools Manuf 39(12):1903–1923

Uhlmann E, Mihotovic V, Coenen A (2009) Modelling the abrasive flow machining process on advanced ceramic materials. J Mater Process Technol 209(20):6062–6066

Howard M, Cheng K (2013) An industrially feasible approach to process optimisation of abrasive flow machining and its implementation perspectives. Proc Inst Mech Eng B J Eng Manuf 227(11):1748–1752

Davies PJ, Fletcher AJ (1995) The assessment of the rheological characteristics of various polyborosiloxane/grit mixtures as utilized in the abrasive flow machining process. Proc Inst Mech Eng C J Mech Eng Sci 209(6):409–418

Jain RK, Jain VK (2001) Specific energy and temperature determination in abrasive flow machining process. Int J Mach ToolsManuf 41(12):1689–1704

Wang AC, Liu CH, Liang KZ, Pai SH (2007) Study of the rheological properties and the finishing behavior of abrasive gels in abrasive flow machining. J Mech Sci Technol 21(10):1593–1598

Wan S, Ang YJ, Sato T, Lim GC (2014) Process modeling and CFD simulation of two-way abrasive flow machining. Int J Adv Manuf Technol 71(5):1077–1086

Fu Y, Gao H, Yan QS, Wang XP, Wang X (2020) Rheological characterisation of abrasive media and finishing behaviours in abrasive flow machining. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-020-05288-9

Jain RK, Jain VK (2014) Finite element simulation of abrasive flow machining. Proc Instn Mech Engrs Part B: J Engineering Manufacture 21:1723–1736

Uhlmann E, Doits M, Schmiedel C (2013) Development of a material model for viscoelastic abrasive media in abrasive flow machining. Proceeding of 14th CIRP conference on modelling of Machining Operations.

Uhlmann E, Schmiedel C, Wendler J (2015) CFD simulation of abrasive flow machining process. Proceeding of 15th CIRP conference on modelling of Machining Operations. pp 209-214.

Cheng K, Shao Y, Bodenhorst R, Jadva M (2017) Modeling and simulation of material removal rates and profile accuracy control in abrasive flow machining of the integrally bladed rotor blade and experimental perspectives. Trans J Manuf Sci Eng 139(12):121020–121,028

Singh S, Ravi Sankar M, Jain VK (2017) Simulation and experimental investigations into abrasive flow nanofinishing of surgical stainless steel tubes. Mach Sci Technol:1–22

Jain VK, Kumar R, Dixit PM, Sidpara A (2009) Investigations into abrasive flow finishing of complex workpieces using FEM. Wear 267(1):71–80

Dong Z, Ya G, Liu J (2015) Study on machining mechanism of high viscoelastic abrasive flow machining for surface finishing. Proc ImechE Part B: J Engineering Manufacture 231(4, 608):–617

Buscall R (2010) Wall slip in dispersion rheometry. J Rheol 54:1177

Sergul AC, Ulku Y (2005) Effect of volume fraction and particle size on wall slip in flow of polymeric suspensions. J Appl Polym Sci 98(1):439–448

Guénette R, Fortin M (1995) A new mixed finite element method for computing viscoelastic flows. J Non-Newtonian Fluid Mech 60(1995):27–52

Fattal R, Kupferman R (2005) Time-dependent simulation of viscoelastic flows at high Weissenberg number using the log-conformation representation. J Non-Newtonian Fluid Mech 126(1):23–37

Balci N, Thomases B, Renardy M, Doering CR (2011) Symmetric factorization of the conformation tensor in viscoelastic fluid models. J Non-Newtonian Fluid Mech 166(11):546–553

Stewart PA, Lay N, Sussman M, Ohta M (2008) An improved sharp interface method for viscoelastic and viscous two-phase flows. J Sci Comput 35(1):43–61

Chen XY, Marschall H, Schafer M, Bothe D (2013) A comparison of stabilisation approaches for finite-volume simulation of viscoelastic fluid flow. Int J Comp Fluid Dynamics 27:229–250

Thien NP, Tanner RI (1977) A new constitutive equation derived from network theory J Non-Newtonian Fluid Mech, v2, n4, p 353 p365, ISSN 03770257

Bird RB, Armstrong RC, Hassager O (1987) Dynamics of polymeric liquids, Fluid Mechanics, vol 1. John Wiley, New York

Macosko C (1994) Rheology: principles, measurements and applications. Publishers, VCH

Patankar SV, Spalding DB (1972) A calculation procedure for heat, mass and momentum transfer in three-dimensional Parabolic flow. Int Heat Mass Transf 115:1787–1803

IHPC-TD-FD-2017-021. Method, apparatus and system for measuring the rheology of freely slipping AFM media

Acknowledgments

The authors would like to thank Dr. Kang Chang Wei (Deputy Director, Fluid Dynamics Department, Institute of High Performance Computing, Singapore) for his contributions to support and resolve the issues that arose during the conduct of the research reported here. His experience in guiding and improving the manuscript is very beneficial. We also acknowledge the support of computational facilities from the National Supercomputer Centre (NSCC) in Singapore, without which the simulations undertaken in the present work would not have been possible.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

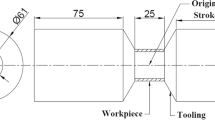

Drawings of branching geometries

Drawings of branching geometries

Rights and permissions

About this article

Cite this article

Chih-Hua, W., Chun Wai, K., Stephen Yee Ming, W. et al. Numerical and experimental investigation of abrasive flow machining of branching channels. Int J Adv Manuf Technol 108, 2945–2966 (2020). https://doi.org/10.1007/s00170-020-05589-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05589-z