Abstract

Tool condition monitoring (TCM) during the manufacturing process is of great significance for ensuring product quality and plays an important role in intelligent manufacturing. Current TCM systems deployed in the local device or cloud computing environment unable meet the requirements of low response latency and high accuracy at the same time. The emerging fog computing provides new solutions for the above problem. This paper presents a tool wear monitoring and prediction (TWMP) system based on deep learning models and fog computing. In order to improve monitoring and prediction accuracy, we propose a multiscale convolutional long short-term memory model (MCLSTM) to complete the tool wear monitoring task and a bi-directional LSTM model (BiLSTM) to complete the tool wear prediction task. To reduce the response latency of the TWMP system, we deploy the MCLSTM model and the BiLSTM model in a fog computing architecture. The fog computing architecture consists of an edge computing layer, a fog computing layer, and a cloud computing layer. The edge computing layer undertakes real-time signal collection task. The fog computing layer undertakes real-time tool wear monitoring task. The cloud computing layer with powerful computing resources undertakes intensive computing and latency-insensitive tasks such as data storage, tool wear prediction, and model training. A twist drill wear monitoring and prediction experiment is conducted to test the performance of the proposed system in terms of accuracy, response time, and network bandwidth consumption.

Similar content being viewed by others

Abbreviations

- IIOT:

-

Industry internet of things

- TWMP:

-

Tool wear monitoring and prediction

- TCM:

-

Tool condition monitoring

- LSTM:

-

Long short-term memory

- CNN:

-

Convolutional neural network

- MCLSTM:

-

Multiscale convolutional long short-term memory

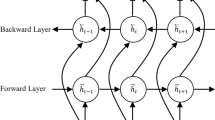

- BiLSTM:

-

Bi-directional long short-term memory

- DBN:

-

Deep belief network

- SAE:

-

Sparse autoencoders

- CBLSTM:

-

Convolutional bi-directional long short-term memory

- MCNN:

-

Multiscale convolutional neural network

- MLSTM:

-

Multiscale long short-term memory

- FC:

-

Fully connected

- BN:

-

Batch normalization

- MAPE:

-

Mean absolute percentage error

- RMSE:

-

Root mean squared error

- GRU:

-

Gated recurrent unit

- BiGRU:

-

Bi-directional gated recurrent unit

References

Fatemeh A, Antoine T, Marc T (2018) Tool condition monitoring using spectral subtraction and convolutional neural networks in milling process. Int J Adv Manuf Technol 98:3217–3227. https://doi.org/10.1109/ICSensT.2016.7796266

Lei Y, Jia F, Lin J, Xing SB, Ding SX (2016) An intelligent fault diagnosis method using unsupervised feature learning towards mechanical big data. IEEE Trans Ind Electron 63(5):3137–3147. https://doi.org/10.1109/TIE.2016.2519325

Scheffer C, Engelbrecht H, Heyns PS (2005) A comparative evaluation of neural networks and hidden Markov models for monitoring turning tool wear. Neural Comput Applic 14(4):325–336. https://doi.org/10.1007/s00521-005-0469-9

Yu J, Liang S, Tang D, Liu H (2017) A weighted hidden Markov model approach for continuous-state tool wear monitoring and tool life prediction. Int J Adv Manuf Technol 91(1-4):201–211. https://doi.org/10.1007/s00170-016-9711-0

Lu Z, Wang M, Dai W (2019) In-process complex machining condition monitoring based on deep forest and process information fusion. Int J Adv Manuf Technol 104(7-8):1953–1966. https://doi.org/10.1007/s00170-019-03919-4

Li N, Chen Y, Kong D, Tan S (2017) Force-based tool condition monitoring for turning process using v-support vector regression. Int J Adv Manuf Technol 91(1-4):351–361. https://doi.org/10.1007/s00170-016-9735-5

Cuka B, Kim DW (2017) Fuzzy logic based tool condition monitoring for end-milling. Robot Comput Integr Manuf 47:22–36. https://doi.org/10.1016/j.rcim.2016.12.009

Hinton GE, Salakhutdinov RR (2006) Reducing the dimensionality of data with neural networks. Science 313(5786):504–507. https://doi.org/10.1126/science.1127647

Bengio Y, Delalleau O (2011) On the expressive power of deep architectures. Proceedings of the 14th International Conference on Discovery Science 2011: 18-36

Gers FA, Schmidhuber J, Cummins F (1999) Learning to forget: continual prediction with LSTM. Neural Comput. Proceedings of the 1999 the 9th International Conference on Artificial Neural Networks 1999: 850-855. https://doi.org/10.1049/cp:19991218

Qiao H, Wang T, Wang P, Zhang L, Xu M (2019) An adaptive weighted multiscale convolutional neural network for rotating machinery fault diagnosis under variable operating conditions. IEEE Access 7:118954–118964. https://doi.org/10.1109/ACCESS.2019.2936625

Teerapittayanon S, McDanel B, Kung HT (2017) Distributed deep neural networks over the cloud, the edge and end devices. Proceedings of the 37th IEEE International Conference on Distributed Computing Systems 2017: 328-339. https://doi.org/10.1109/ICDCS.2017.226

Gao R, Wang L, Teti R, Dornfeld D, Kumara S, Mori M, Helu M (2015) Cloud-enabled prognosis for manufacturing. CIRP Ann 64(2):749–772. https://doi.org/10.1016/j.cirp.2015.05.011

Wu D, Jennings C, Terpenny J, Kumara S, Gao RX (2018) Cloud-based parallel machine learning for tool wear prediction. J Manuf Sci Eng, Trans ASME 140(4):041005–041015. https://doi.org/10.1115/1.4038002

Caggiano A (2018) Cloud-based manufacturing process monitoring for smart diagnosis services. Int J Comput Integr Manuf 31(7):612–623. https://doi.org/10.1080/0951192X.2018.1425552

Bonomi F, Milito R, Zhu J (2012) Fog computing and its role in the internet of things. Proc First Ed MCC Workshop Mobile Cloud Comput 2012:13–16. https://doi.org/10.1145/2342509.2342513

Bonomi F, Milito R, Natarajan P, Zhu J (2014) Fog computing: a platform for internet of things and analytics. Big Data Internet Things: Roadmap Smart Environ 2014:169–186. https://doi.org/10.1007/978-3-319-05029-4_7

Chen Y, Jin Y, Jiri G (2018) Predicting tool wear with multi-sensor data using deep belief networks. Int J Adv Manuf Technol 99(5-8):1917–1926. https://doi.org/10.1007/s00170-018-2571-z

Shi C, Panoutsos G, Luo B, Liu H, Li B, Lin X (2019) Using multiple-feature-spaces-based deep learning for tool condition monitoring in ultraprecision manufacturing. IEEE Trans Ind Electron 66(5):3794–3803. https://doi.org/10.1109/TIE.2018.2856193

Zhao R, Wang J, Yan R, Mao K (2016) Machine health monitoring with LSTM networks. Proc Int Conf Sens Technol 2016:1–6. https://doi.org/10.1109/ICSensT.2016.7796266

Wang J, Zhao R, Wang D, Yan R, Mao K, Shen F (2017) Machine health monitoring using local feature-based gated recurrent unit networks. IEEE Trans Ind Electron 65(2):1539–1548. https://doi.org/10.1109/ICSensT.2016.7796266

Tao Z, An Q, Liu G, Chen M (2019) A novel method for tool condition monitoring based on long short-term memory and hidden Markov model hybrid framework in high-speed milling Ti-6Al-4V. Int J Adv Manuf Technol 105(7-8):3165–3182. https://doi.org/10.1007/s00170-019-04464-w

Cao X, Chen B, Yao B, He W (2019) Combining translation-invariant wavelet frames and convolutional neural network for intelligent tool wear state identification. Comput Ind 106:71–84. https://doi.org/10.1016/j.compind.2018.12.018

Qiao H, Wang T, Wang P, Qiao S, Zhang L (2018) A time-distributed spatiotemporal feature learning method for machine health monitoring with multi-sensor time series. Sensors 18(9):2932. https://doi.org/10.3390/s18092932

Zhao R, Yan R, Wang J, Mao K (2017) Learning to monitor machine health with convolutional bi-directional LSTM networks. Sensors 17(2):273. https://doi.org/10.3390/s17020273

Wu D, Liu S, Zhang L, Terpenny J, Gao R, Kurfess T, Guzzo JA (2017) A fog computing-based framework for process monitoring and prognosis in cyber-manufacturing. J Manuf Syst 43:25–34. https://doi.org/10.1016/j.jmsy.2017.02.011

Li L, Ota K, Dong M (2018) Deep learning for smart industry: efficient manufacture inspection system with fog computing. IEEE Transact Industrial Inform 14(10):4665–4673. https://doi.org/10.1109/TII.2018.2842821

O’Donovan P, Gallagher C, Leahy K, O’Sullivan DTJ (2019) A comparison of fog and cloud computing cyber-physical interfaces for Industry 4.0 real-time embedded machine learning engineering applications. Comput Ind 110:12–35. https://doi.org/10.1109/TII.2018.2842821

Jiang G, He H, Yan J, Xie P (2018) Multiscale convolutional neural networks for fault diagnosis of wind turbine gearbox. IEEE Trans Ind Electron 66(4):3196–3207. https://doi.org/10.1109/TIE.2018.2844805

Glorot X, Bordes A, Bengio YS (2011) Deep sparse rectifier neural networks. Proceedings of the 14th international conference on artificial intelligence and statistics (AISTATS). J Mach Learn Res 2011:315–323

Loffe S, Szegedy C (2015) Batch normalization: accelerating deep network training by reducing internal covariate shift. Proceedings of the 32nd International Conference on Machine Learning 2015: 448-456

Matthew DZ (2012) Adadelta: an adaptive learning rate method. arXiv preprint. Computer Science, arXiv:1212.5701

Harun MHS, Ghazali MF, Yusoff AR (2017) Analysis of tri-axial force and vibration sensors for detection of failure criterion in deep twist drilling process. Int J Adv Manuf Technol 89(9–12):3535–3545

Funding

This work is supported by the National Natural Science Foundation of China (Grant No. 51975402).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qiao, H., Wang, T. & Wang, P. A tool wear monitoring and prediction system based on multiscale deep learning models and fog computing. Int J Adv Manuf Technol 108, 2367–2384 (2020). https://doi.org/10.1007/s00170-020-05548-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05548-8